Mechanical and physical properties of Cunninghamia lanceolata wood decayed by brown rot

iForest - Biogeosciences and Forestry, Volume 12, Issue 3, Pages 317-322 (2019)

doi: https://doi.org/10.3832/ifor2922-012

Published: Jun 06, 2019 - Copyright © 2019 SISEF

Research Articles

Abstract

The relationship between the mechanical properties of Cunninghamia lanceolata (Chinese fir) wood and the development of fungal decay was investigated with the aim of implementing a statistical model useful as a non-destructive and a fast method for determining the state of conservation of in-service timber structures. Artificial decay due to brown rot fungi was induced on wood specimens and physical and mechanical test were performed periodically, as well as anatomical observation of wood, FT-IR spectroscopic and XRD diffraction analysis. As a result, Chinese fir was confirmed to have a good durability against fungi, showing a mass loss percentage of 7.21% on average after 14 weeks of exposure. On the contrary, the mechanical properties reduced dramatically during the decay test: a 19% decrease was observed for compression strength and 21% for tensile strength. The mechanism of decay was explored and the corresponding damage constitutive model was proposed.

Keywords

Wooden Construction, Brown Rot, Mass Loss Rate, Wood Decay, Wood Strength

Introduction

In China, wood has been utilized since antiquity as building material for civil and cultural heritage architecture. Especially in the South of the country, Chinese fir (Cunninghamia lanceolata [Lamb.] Hook.) was often the timber species chosen to this aim ([20]). Indeed, Chinese fir is a fast-growing straight tree whose content in extractives confers to the wood a good natural durability ([12], [2]).

At present, in the country the performance of the materials used for historical building construction and the structural and mechanical behaviour of the wooden buildings are determined principally during emergency reparations and strengthening research projects. Instead, it would be highly desirable to assess the performance of wood based on the knowledge of both the inherent durability and the climatic conditions (climate and microclimate) where the building is placed. This can also help planning the proper interventions of maintenance during the service life ([22]).

The aim of this study is to find the relationships between the mechanical properties of Chinese fir wood and the development of fungal decay, aimed at the implementation of a statistical model useful as a non-destructive and a fast method for determining the state of conservation of in-service timber structures.

In the past, Wilcox ([24]) reviewed the effect of the early decay on wood strength and reported that, referred to brown rot decay on softwood, toughness and impact bending decreased of 60-80% when the fungal decay, measured as mass loss percentage was around 5-10%. Later, Winandy & Morrell ([25]) found a linear relationship between the weight losses due to brown rot and the bending strength losses in Douglas fir (Pseudotsuga menziesii). A drastic decrease in bending strength and modulus of elasticity (MOE) was observed in Scots pine during the initial phase of decay and this change was exponential: a 50% decrease in bending strength for 7% of mass loss in the case of brown rot and 20% for white rot; MOE values were reduced by about 50% in the case of white rot for a mass loss of 40%, while for brown rot a 50% decrease in MOE was found after a mass decrease as low as 20% ([26]). Looking at these findings, other authors proposed to use wood MOE as an indicator of rot-fungal attack, and the results showed actually that it is a sensitive and reliable indicator of rot-fungal attack, regardless of fungus or wood species. The MOE analysis of untreated wood reduced the 12- to 16-week exposure time necessary for the standard mass loss measurement to four weeks ([13]).

In the same context, Chen ([1]) performed accelerated decay tests on Chinese fir by brown rot Gloeophyllum trabeum, finding that, when the wooden mass loss rate was 1.35%, 5.03% and 10.12%, the tensile strength parallel to grain of the decayed specimens was reduced of 5.52%, 13.21% and 29.86% respectively. He also found a relationship among decay, wooden chemical components and the corresponding mechanical strength and suggested that brown-rot fungus reduced the wooden strength for cellulose’s depolymerization by combining the evidences found through the FT-IR spectroscopy, the electron-scanning microscope, and the X-ray powder diffraction techniques ([1]). Cowling ([3]) added that, even when the wooden mass loss rate is low, brown-rot fungus can reduce the wooden degree of polymerization rapidly (from 1800-2000 to 150-200 glucose units). Moreover, Curling et al. ([4]) explored the relationship between the degradation of hemicelluloses and the reduction of wooden mechanical strength, i.e., the reduction of arabinose and galactose can be associated to an early mechanical strength decrease (up to 40%), whereas the reduction of mannose and xylan can be observed when the mechanical strength loss is over 40%. Contrastigly, Pizzo et al. ([19]) demonstrated that the strength reduction is imputable to both the mass loss occurred in the wood and the different chemical composition between fresh and decayed material; namely, the residual strength of the wood is strongly associated to the effective content of holocellulose.

Little research has been done on the development of a constitutive model for decayed wood. Tagarielli et al. ([21]) implemented a constitutive model of undamaged wood and developed the corresponding formulations. Wang ([23]) divided the constitutive model into two stages, and simplified them to a linear equation. Working with aged wood, Yokoyama et al. ([27]) found that the ultimate flexural capacity, rupture energy and fracture strain limits were all lower than those of the original wood, whereas the elastic limit strain was higher. Furthermore, Li ([10]) established the aged wooden strength formulation and suggested a calculation method for degenerated strength of timber structural element by comparing aged and fresh Cathay poplar. Finally, it was recently reported that multivariate analyses of biochemical and physic-chemical data allowed the prediction of wood strength with accuracy, validated by experimental measurement of the compression parallel to the grain ([9]).

In this paper, the relationship between different degrees of wood decay and the corresponding mechanical properties has been explored and a model for fungal decayed Chinese fir was proposed. At the same time, the deterioration mechanism of wood decay was investigated by combining the FT-IR, electron-scanning microscope, and XRD analysis.

Material and methods

Specimen preparation

Cunninghamia lanceolata (Chinese fir) 30-year-old trees were sampled from Jiangxi (27 ° 44′ 32″ N, 144° 39′ 13″ E). Totally, 10 logs (average diameter of 24 cm) were collected from the forest according to the Chinese standard GB/T1927-2009, which provides the methods to sample trees for physical and mechanical characterization of the wood. Briefly, the sampled trees had a normal growth, without visible defects and with round and straight trunks; no samples from neighbouring trees were collected.

The wood specimens were then prepared from the logs according to the pattern provided in the Chinese standard GB/T1929-2009 ([15], [16]). Two sets of specimens were prepared, one for compression tests parallel to the grain and the other for tensile tests parallel to the grain. The laths for preparing the specimens were sawn from well-chosen logs following the sawing pattern described by the Chinese standard (GB/T1929-2009). The section size of finish-cutting specimen for compression tests was 20 × 20 mm, while the corresponding height of specimen parallel to the grain was 30 mm. The minimum section size of the effective part of each specimen for tensile test was 15 × 4 mm. Only specimens clear from defects such as pith, cracks, knots and local grain deviation were kept for the study. For each specimen, the ring number, density, location within laths and log were recorded.

Decay induction

The fungus Gloeophyllum trabeum Murr. was cultivated by the Institute of Microbiology of Chinese Academy of Sciences (Beijing, China), according to the Chinese standard GB/T1394 2.1-92 ([17]), which describes the laboratory test method for determining the natural durability of wood.

At first, the culture dishes inoculated with the fungus were put into electro-heating standing-temperature cultivator for one week; the related wood specimens were sterilized in a high-pressure steam sterilization pot in which the normal temperature is 138 °C. The sterilized specimens were then put in contact with the fungus hyphae, maintained in a climatic chamber (T = 28 ± 2 °C; RH = 75-85%) and checked periodically.

A pre-test was performed to assess the time needed for the mycelium to degrade Chinese fir wooden specimens. Lin et al. ([11]) observed a reduction of mechanical strength of 50% already at an early stage of decay (less than 10% of mass loss). According to the pre-test results and the findings by Lin et al. ([11]), the mechanical tests (described below) were performed every 2 weeks, starting from the sound specimens (time 0, before any contact with the fungus) up to 14 weeks after inoculation.

Measurements and tests on decayed specimens

The measurements and the tests performed are summarized in Tab. 1. According to the goals of investigation, ring number, density and the location of each specimen within lath and log, wooden specimens were arranged into four different groups: group 1 for the calculation of the mass loss, groups 2 and 3 for the chemical and mechanical tests, and group 4 for anatomical observations (Tab. 1).

Tab. 1 - Number and type of specimens used for different tests. (N): Replicates per decayed period; (1): “compression type” specimen; (2): “tensile type” specimen.

| Group | Test | Specimen type | N |

|---|---|---|---|

| 1 | Mass loss | 1 | 3 × 8 |

| 2 | Compression parallel to the grain, Chemical components and cellulose crystallinity | 1 | 6 × 8 |

| 3 | Tensile parallel to the grain | 2 | 6 × 8 |

| 4 | Anatomical observations | 1 | 1 × 8 |

Before the tests, all the specimens were kept in the constant temperature-humidity chamber (T = 20 ± 2°C; RH = 60-70%); all specimens were marked and weighted. Only the specimens aimed to the calculation of the mass loss were formerly dried in the oven (T = 100 ± 5 °C) to determine the anhydrous weight and then put in the constant temperature-humidity chamber again to reach the equilibrium moisture content. Afterwards, specimens were inoculated with the fungus and put at constant conditions (T = 28 ± 2 °C; RH = 75-85%) for the scheduled period according to the test scheme.

At the end of each planned decay period, 3 specimens “compressive type” were took out from the chamber, cleaned from superficial mycelium, dried in the oven (T = 100 ± 5 °C), and weighted. The mass loss was calculated as (eqn. 1):

where γm is the mass loss of the specimen; M1 is the dried mass of the specimen after inoculation; M0 is the dried mass of the specimen before the test.

At the same time, 6 specimens for each decay period from group 2 and 3 were at first conditioned at T = 20 ± 2 °C and RH = 60-70% until constant mass, then underwent mechanical and chemical analysis.

The specimens “compression type” underwent the compression test and finally the determination of chemical composition and cellulose crystallinity.

The mechanical tests were performed using a universal testing machine (WDW-20KN®, HST, Jinan Hensgrand Instrument Co., Jinan, China) with an accuracy of 10 N. The compressive load was applied slowly with a loading rate between 200 and 300 kPa per second, in order to reach the failure within 1.5-2.0 minutes. Compression strength parallel to grain was calculated as the load at failure divided by the cross specimen area measured at the testing time. Compression modulus of elasticity (MOE) was determined in the straight line portion of the load-deformation curve.

The modifications of the chemical composition after the compression test were analysed by FT-IR spectrograms (infrared spectroscopic analysis), using the infrared spectrometer Varian® 670-IR+610-IR (Agilent, Santa Clara, CA, USA). For each decay period, 3 specimens “compression type” were chosen randomly and put into the oven up to their dry condition, then ground to powder and briquetted to the transparent ingot by potassium bromide pellet technique, so that the FT-IR spectrograms could be obtained.

The cellulose crystallinity was measured by D8 Advance X-ray Powder Diffractometer (Bruker, Billerica, MS, USA). The powder was scanned by the XRD in the scan range 5°-45° and at the 0.1° sec-1 scan speed in triplicates.

As for the specimens of group 3, six specimens per decay period were tested in tension parallel to the grain using the same machine described above for the compression tests. The two ends of the specimens were clamped in the grips of the testing machine so that the wider side was in contact with the grips and at a distance of at least 20-25 mm from the gauge portion. The specimens were mounted vertically. The load was applied slowly with a loading rate between 200 and 300 kPa per second. Tensile strength parallel to grain was calculated as the load at failure divided by the cross area of the gauge portion measured at the testing time; tensile modulus of elasticity was determined in the straight-line portion of the load-deformation curve.

Finally, one specimen “compression type” per each decay period was kept for the anatomical analysis, performed by an environmental scanning electron microscope (XL-30 ESEM, FEI/Philips, Hillsboro, OR, USA). A transverse section (1 mm thick) was cut from the decayed surface of the specimens, polished and observed by the ESEM.

Data analysis and definition of Decay Constitutive Model (DCM)

Data analysis

The results of mechanical tests were used to calculate the loss of mechanical performance as the ratio between the mechanical property of sound specimens (before the inoculation with fungi) and the same property measured at several times along the decay period. The loss of performance was related to the mass loss, hereafter indicated as “decay ratio”. The values were fitted with linear and polynomial regression.

Definition of DCM

The stress-strain curves of each specimen were obtained directly during the mechanical test. Thus, the average stress-strain curve of specimens of each decayed condition for compression and tensile tests were calculated. The DCM consisted of the average stress-strain curves of 8 different decayed condition for “compressive type” and “tensile type”.

Results and discussion

Artificial decay

After decay induction, the mass loss rate at each decay period was calculated and the results are shown in Tab. 2. These results confirmed the good natural durability of Chinese fir against rot fungi ([12], [2]), since after 14 weeks of exposure to fungal attacks, the wood material lost only 7.21% of its mass, on average.

Tab. 2 - Average mass loss of the wood samples at different stages of decay after inolculation.

| Decay period (weeks) | Mass loss rate (%) |

|---|---|

| 0 | 0 |

| 2 | 0.24 |

| 4 | 0.9 |

| 6 | 1.4 |

| 8 | 2 |

| 10 | 3.34 |

| 12 | 5.36 |

| 14 | 7.21 |

The percentage of mass loss is hereafter indicated as decay ratio (γm). The consequent reduction in mechanical properties was analysed to establish the relationship between the decay ratio and the loss of performance of the material.

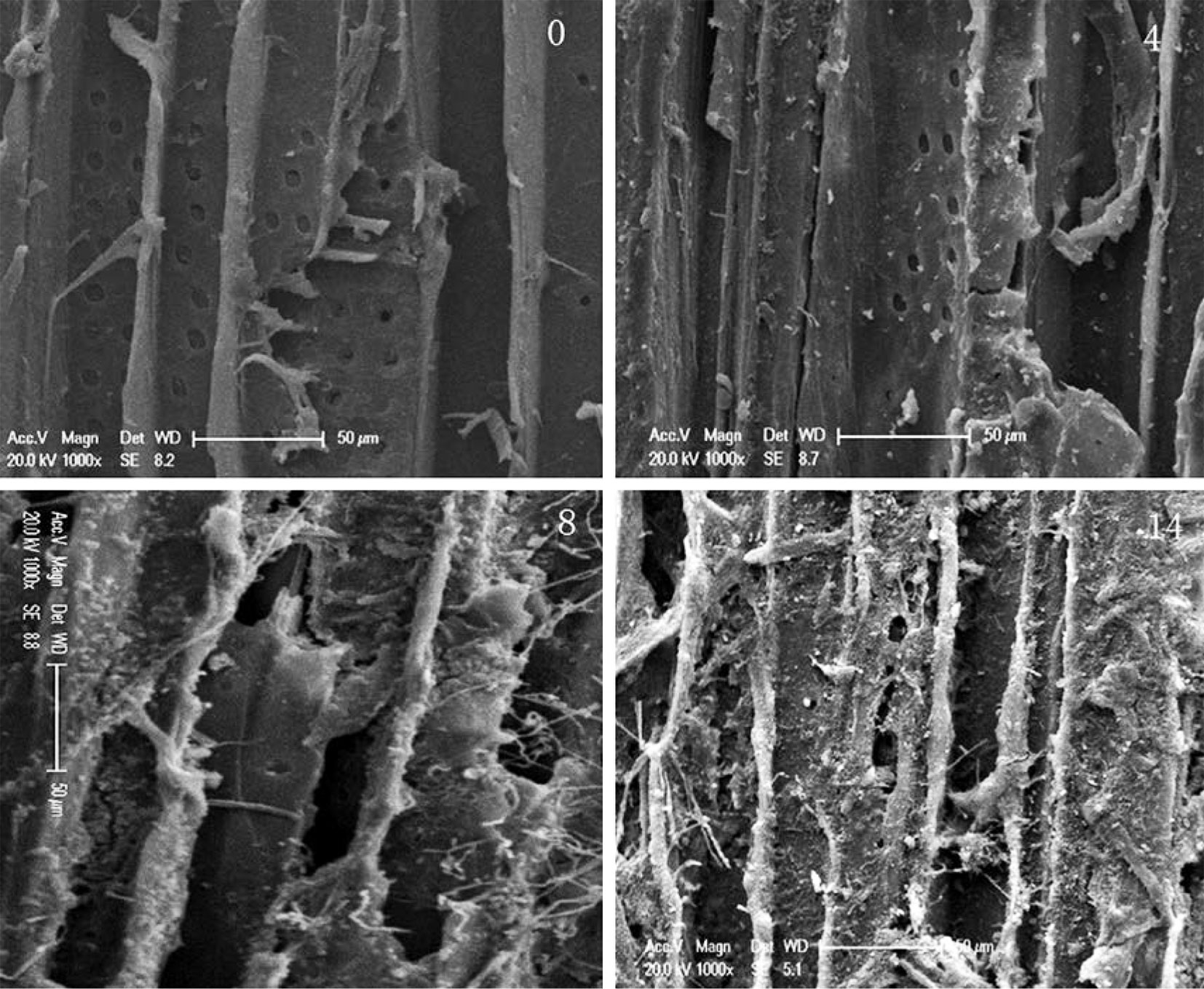

The anatomical analysis showed the evolution of microstructure pattern of Chinese fir wood. Some longitudinal anatomical pictures of samples at 0, 4, 8 and 14 week of fungal exposure are shown in Fig. 1. There were no hyphens visible within the tracheid walls at the beginning, but during the first four weeks of degradation brown-rot fungi spread into the wood and multiplied rapidly, scattering around the pits and spreading to other cells through pits. The bordered pits seemed damaged, in facts most of the torus disappeared. At this stage, apparently only bordered pits showed traces of the attack, while fungus did not degrade the cell wall seriously. After 8 weeks, there was mass hyphae within the lumina of the tracheids and the hyphae had invaded and damaged the cell walls. At the same time, the mass and the mechanical properties of those specimen decrease rapidly. After 14 weeks, the tracheid walls appeared decayed and damaged, even if the mass loss was less than 10%. According to the literature ([6]), brown rot fungi mostly depolymerize the holocellulose, causing the reduction in the strength and elastic property of wood, though the mass loss was below 10% ([19]).

Fig. 1 - Changes in anatomical characteristics of a Chinese fir wood specimens inoculated with the fungus Gloeophyllum trabeum at several stages of decay (0, 4, 8, and 14 weeks after inoculation).

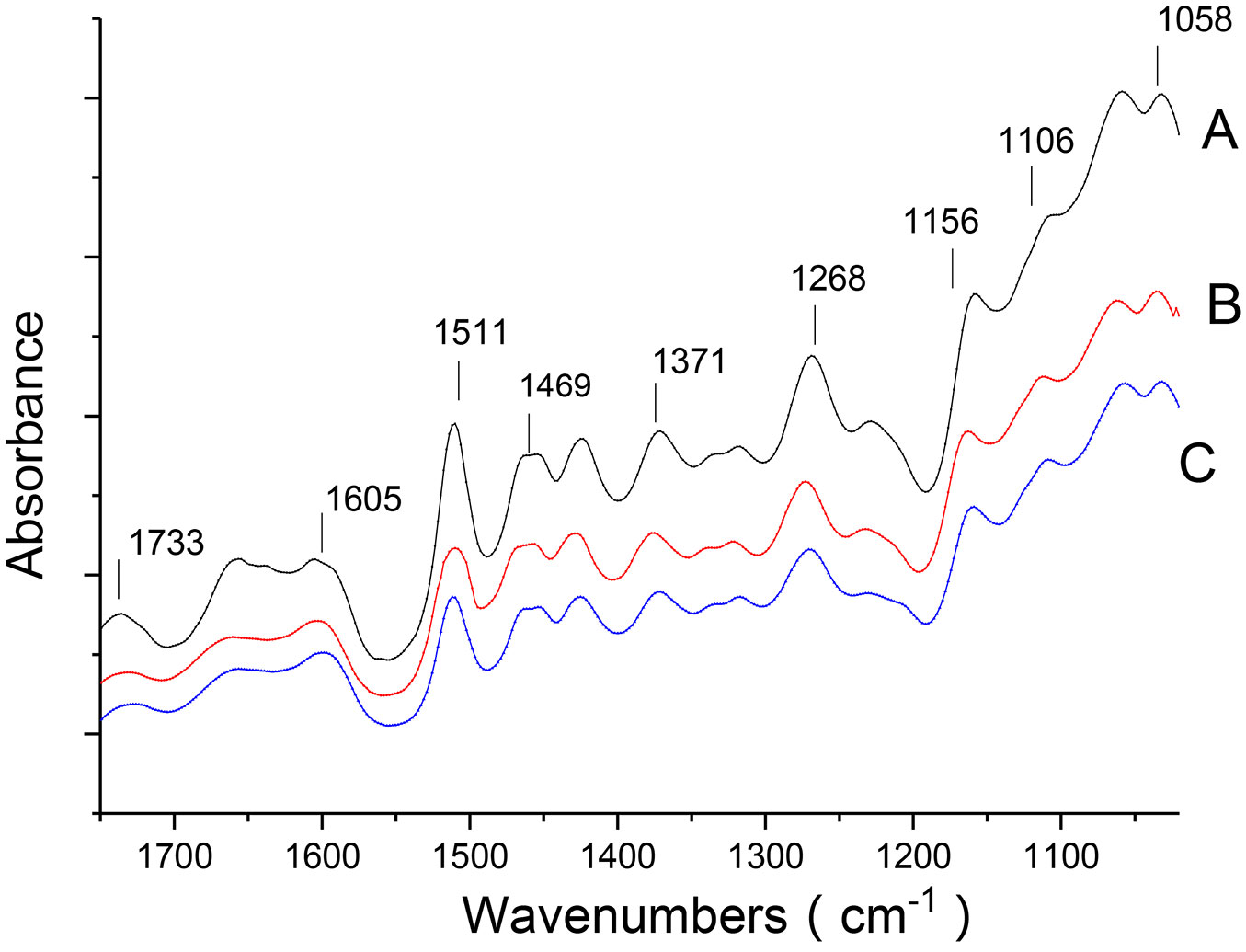

There is a wide scientific literature about the use of infrared spectroscopic analysis as a tool for deep investigations on the decay of wood constitutive molecules by fungal rot ([8]), through the evaluation of the molecular interaction between wood polymers and hydrogen bonding within and between cellulose chains ([14]). Using FTIR and XRD analysis, changes in the molecular structure and cell wall composition due to brown rot attack can be studied ([7], [5]). FTIR spectrograms (Fig. 2) of the specimens at 0, 6, 14 weeks of decay period revealed that the peaks at 1156 cm-1 (C-O-C), 1106 cm-1 (C-OH), and 1058 cm-1 (C-O), which are corresponding to holocellulose bonds, decreased with increasing the degradation by fungi. In particular, the intensity dropped more rapidly after 6 weeks. This is due to the fact that in the initial decay period, the fungus feeds on the nutriment of culture medium and wooden cell; but after 6 weeks, when the agar nutrients are exhausted, the fungus degrades more intensely the cell wall, leading to the reduction of the mass and mechanical properties. Moreover, the peak at 1511 cm-1 (C=C), corresponding to lignin, did not change so much during the experiment. Therefore, the chemical analysis confirmed that the cellulose and hemicellulose were degraded by the fungus, whereas the lignin was less degraded, as expected by a brown rot agent ([6]). On the opposite, the intensity of 1371 cm-1 (C-H, associated to polysaccharide), 1469 cm-1 (C-H, associated to lignin) peaks did not change so much during the test, which is in agreement with the findings by Witomski et al. ([26]). Compared to the decayed wood in the waterlogged conditions ([11], [18]), the intensity of 1370 cm-1 (C-H), 1158 cm-1 (C-O-C), and 1104 cm-1 (O-H) was decreased, while the 1733 cm-1 (C=O) was also decreased, which is contrasting with out results. This may be due to the fact that the wood here was less decayed out and in different conditions.

Fig. 2 - FTIR spectrogram of the specimens for o (A), 6 (B), 14 (C) weeks of contact with brown rot fungi.

The XRD diffraction analysis of the specimens after 0, 6, 10, 14 weeks of exposure to fungi degradation revealed that the cellulose crystallinity decreased rapidly during the test. The peak dropped more rapidly in later periods, because at that time the fungi all survived depolymerizing cellulose and hemicellulose, as already detected by FTIR analysis.

Mechanical properties

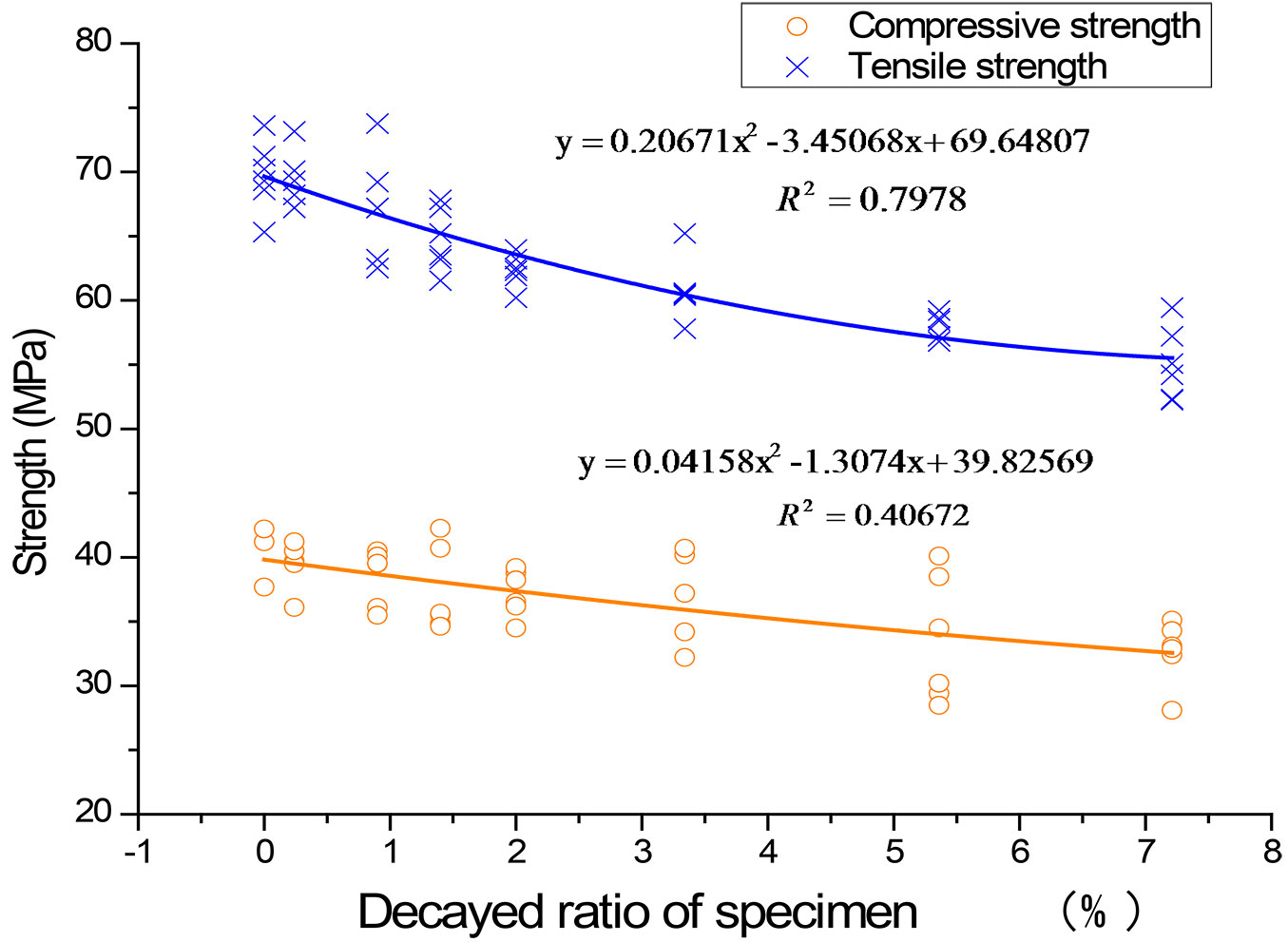

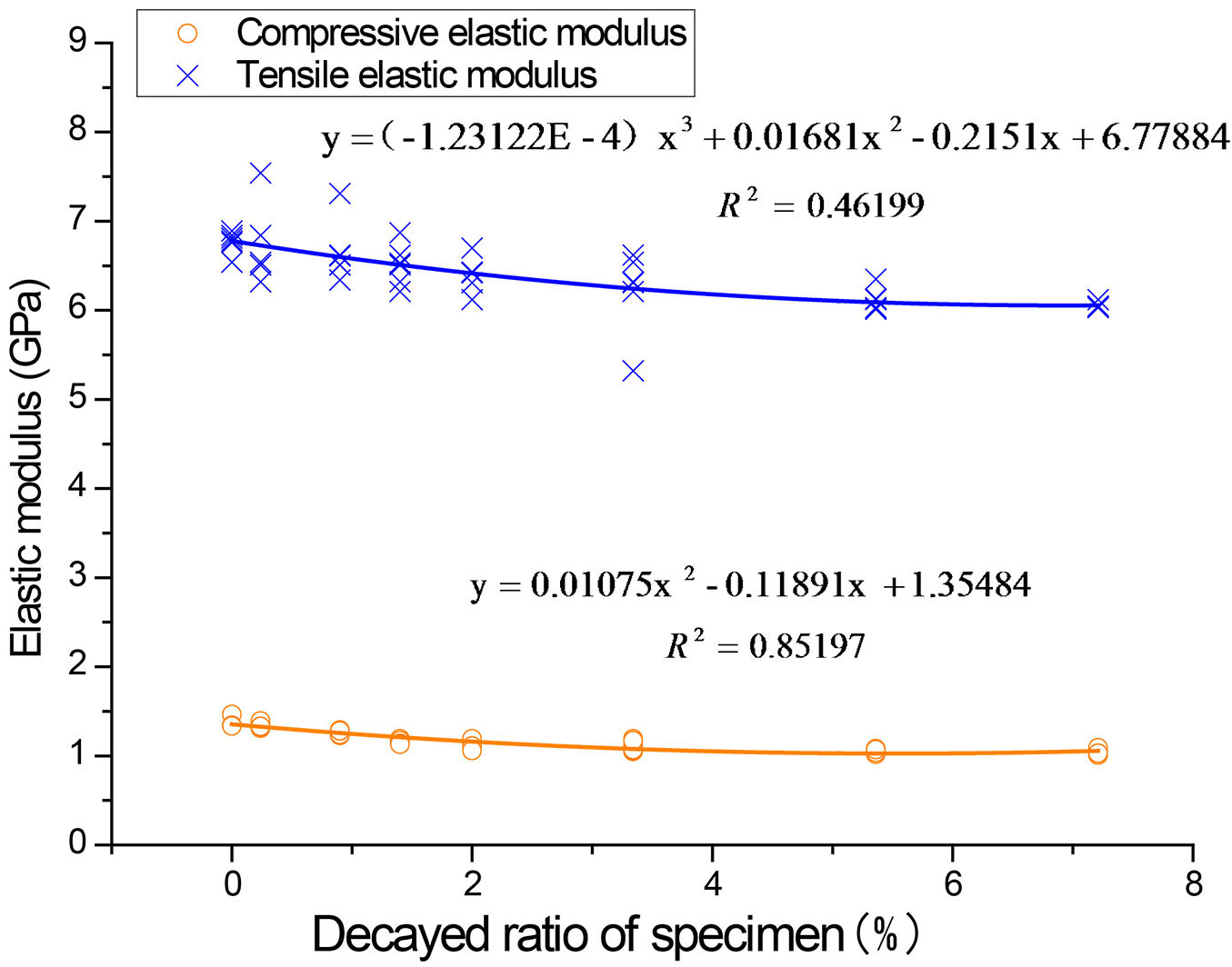

The relationship between mechanical performances (strength and modulus of elasticity) and relative decay ratio was fit based on the test data (Fig. 3, Fig. 4). As expected, both compressive and tensile properties decreased with increasing the decay rate. The loss of strength properties, both tensile and compressive, can be described as merely constant with the development of degradation by fungi. A linear relationship between mass loss and strength properties was found for Douglas fir in bending ([25]) and for Scot pine in compression ([26]), while for the last species, the relationship between bending strength and mass loss was better described by an exponential function ([26]).

After 14 weeks there was 7.21% of mass loss. Correspondingly, the compression strength decreased by 19.1% and the tensile strength by 21%. The results are consistent with previous similar analysis on Chinese fir wood ([1]). On the contrary, elastic properties were better described using polynomial regression (Fig. 3, Fig. 4); both compression and tensile elastic moduli decreased more rapidly until the 10th week of fungus exposure, after which the reduction in stiffness showed a smaller rate. At the end of the experiment, the modulus of elasticity in compression and tension decreased by 24.6% and 10.6%, respectively.

Decay Constitutive Model (DCM)

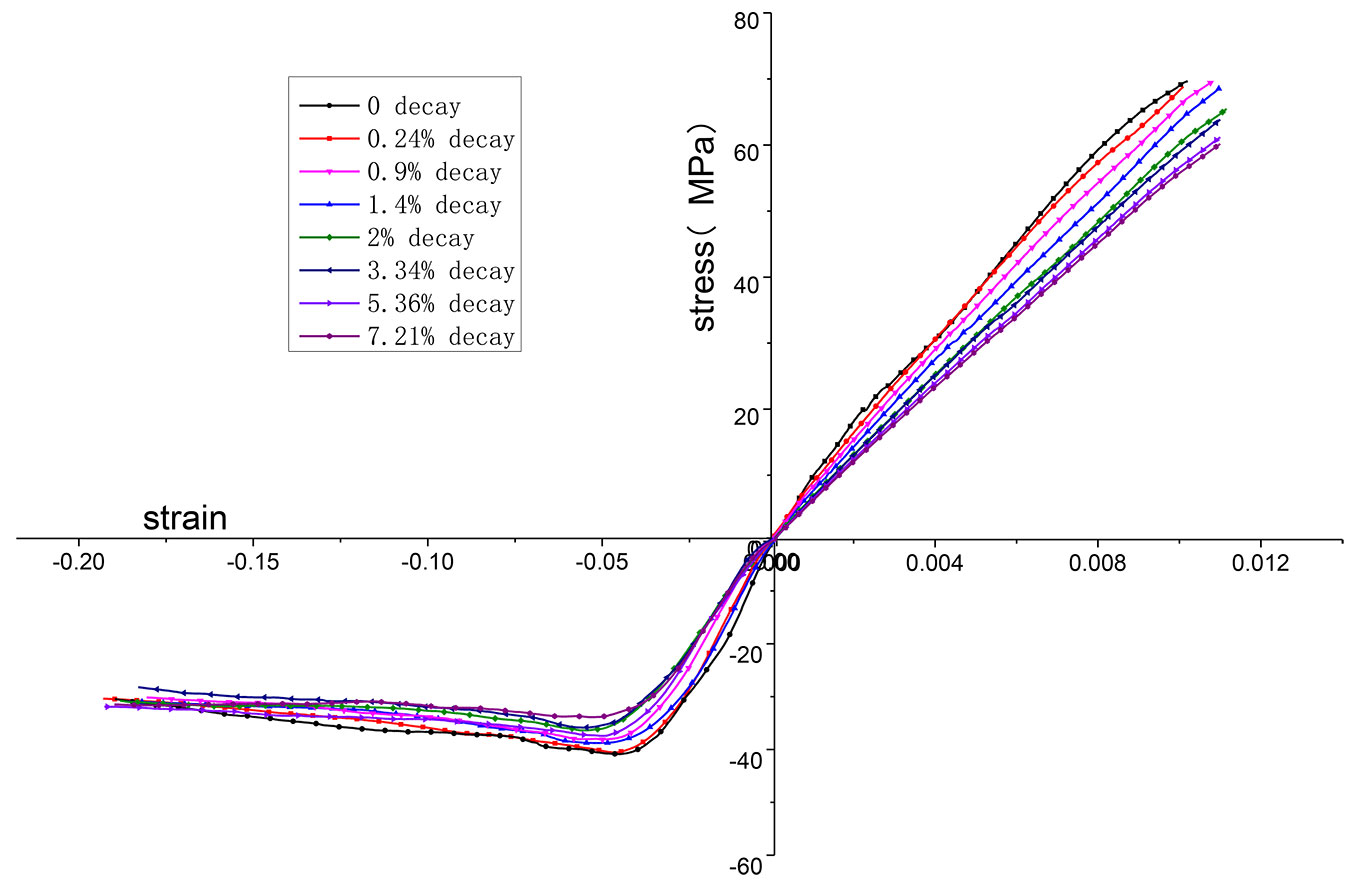

A constitutive model describes the stress-strain (σ-ε) relationship of a material. It is a key attribute, which is applied for structural analysis. The stress-strain curves were obtained during the mechanical tests. Fig. 5 shows the average curve for all the 8 decay periods.

The constitutive model followed the basic relationships of wood material. In order to reflect the influence of the different decay grade on the stress-strain relationship, the decay ratio of the specimens along the entire experiment was included in the model. The decay ratios and the stress-strain curves observed in the mechanical tests were used to establish the mechanical degenerated rule in the so called Decay Constitutive Model. The model obtained is the following (eqn. 2):

Here, γm is the decay obtained from eqn. 1 (mass loss) and the values of ε1, ε2 and ε3 were calculated as follows (eqn. 3):

The model can be divided into four phases: when the values of strain and stress are positive, the wood material is in the stage of tension: (1) the relationship of σ-ε follows the elastic constructive relation. When the values of strain and stress are negative, the wood material is in the stage of compression and the relationship of σ-ε present three kind of stages with different features. That is, (2) ε2 ≤ ε ≤ 0, the relationship of σ-ε follows elastic constructive relation; (3) ε1 ≤ ε ≤ ε2, the relationship of σ-ε follows elastic-plastic constructive relation; (4) ε ≤ ε1, the relationship of σ-ε follows plastic constructive relation.

The model was based on the test data with a decay ratio between 0 and 7.21%, thus it should be applied for decay levels lower than 7.21%.

From DCM, the specimen for compressive strength parallel to grain were in the elastic stage under invariable original loads. At this time, the loads and the deformation were kept in a linear stage. After it reached the compressive yield stress, the specimen can turn into the elastic-plastic stage. Lastly, it was the failure stage when it reached the ultimate compressive strength with the obvious residual strength. Comparing the stress-strain curves of different decay situation, the ultimate compressive strength decreases during the test, so did the elastic modulus, and the decrease became faster after 6 weeks of exposure to brown rot fungus. However, the specimen for tensile strength parallel to grain were in the elastic stage under invariable original loads, and then turn into the failure stage when it reached the ultimate tensile strength with no residual strength. Comparing the stress-strain curves of different decay situation, the ultimate tensile strength and elastic modulus both decrease during the test, and the decrease became faster after 4 weeks of exposure to the fungus.

Conclusion

The decay test revealed that the mean mass loss percentage after 14 weeks was 7.21%, indicating that Chinese fir wood has a good intrinsic resistance against brown rot G. trabeum. The mechanical properties decreased more dramatically than the physical ones during the decay test: after fourteen weeks of decay, the compressive strength decreased by 19% and the tensile strength by 21%. The relationship between strength and mass loss can be described by a linear function, while the relationship between the modulus of elasticity and decay percentage is better described by a polynomial function.

The cell wall is seriously damaged by fungal rot, which drastically decreases hemicellulose and crystalline cellulose content, thus reducing the mechanical properties of wood.

The constitutive model of the decay specimen could be divided into four stages: compressive elastic stage, compressive elastic-plastic stage, compressive plastic stage, tensile elastic stage.

Acknowledgements

This paper is supported by the National Natural Science Foundation of China (Grant No. 51478409, 51338001), the State Administration of Foreign Experts Affair (Grant No. GDT20163200026), Program of 100 Foreign Experts in Jiangsu Province (Grant No. JSB2017029)

References

Online | Gscholar

Authors’ Info

Authors’ Affiliation

Yuewen Gao

School of Architectural Science and Civil Engineering, Yangzhou University (China)

Nicola Macchioni 0000-0001-8648-0073

Michela Nocetti

Sabrina Palanti 0000-0002-9033-8827

CNR-IVALSA, v. Madonna del Piano 6, I-50019 Sesto Fiorentino (Italy)

Corresponding author

Paper Info

Citation

Li S, Gao Y, Brunetti M, Macchioni N, Nocetti M, Palanti S (2019). Mechanical and physical properties of Cunninghamia lanceolata wood decayed by brown rot. iForest 12: 317-322. - doi: 10.3832/ifor2922-012

Academic Editor

Rodolfo Picchio

Paper history

Received: Jul 18, 2018

Accepted: Apr 03, 2019

First online: Jun 06, 2019

Publication Date: Jun 30, 2019

Publication Time: 2.13 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2019

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 48463

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 40005

Abstract Page Views: 4020

PDF Downloads: 3573

Citation/Reference Downloads: 0

XML Downloads: 865

Web Metrics

Days since publication: 2458

Overall contacts: 48463

Avg. contacts per week: 138.02

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

Total number of cites (since 2019): 12

Average cites per year: 1.71

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Research Articles

Physical and mechanical characteristics of poor-quality wood after heat treatment

vol. 8, pp. 884-891 (online: 22 May 2015)

Review Papers

Moisture in modified wood and its relevance for fungal decay

vol. 11, pp. 418-422 (online: 05 June 2018)

Research Articles

Density, extractives and decay resistance variabilities within branch wood from four agroforestry hardwood species

vol. 14, pp. 212-220 (online: 02 May 2021)

Research Articles

Characterization of VOC emission profile of different wood species during moisture cycles

vol. 10, pp. 576-584 (online: 08 May 2017)

Research Articles

The physicomechanical and thermal properties of Algerian Aleppo pine (Pinus halepensis) wood as a component of sandwich panels

vol. 15, pp. 106-111 (online: 21 March 2022)

Research Articles

Behavior of pubescent oak (Quercus pubescens Willd.) wood to different thermal treatments

vol. 8, pp. 748-755 (online: 16 February 2015)

Research Articles

Identification of wood from the Amazon by characteristics of Haralick and Neural Network: image segmentation and polishing of the surface

vol. 15, pp. 234-239 (online: 14 July 2022)

Research Articles

Kinetic analysis of poplar wood properties by thermal modification in conventional oven

vol. 11, pp. 131-139 (online: 07 February 2018)

Research Articles

NIR-based models for estimating selected physical and chemical wood properties from fast-growing plantations

vol. 15, pp. 372-380 (online: 05 October 2022)

Research Articles

Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal

vol. 10, pp. 669-679 (online: 11 July 2017)

iForest Database Search

Search By Author

Search By Keyword

Google Scholar Search

Citing Articles

Search By Author

Search By Keywords

PubMed Search

Search By Author

Search By Keyword