Identification of wood from the Amazon by characteristics of Haralick and Neural Network: image segmentation and polishing of the surface

iForest - Biogeosciences and Forestry, Volume 15, Issue 4, Pages 234-239 (2022)

doi: https://doi.org/10.3832/ifor3906-015

Published: Jul 14, 2022 - Copyright © 2022 SISEF

Research Articles

Abstract

The identification of Amazonian timber species is a complex problem due to their great diversity and the lack of leaf material in the post-harvest inspection often hampers a correct recognition of the wood species. In this context, we developed a pattern recognition system of wood images to identify commonly traded species, with the aim of increasing the accuracy and efficiency of current identification methods. We used ten different species with three polishing treatments and twenty images for each wood species. As for the image recognition system, the textural segmentation associated with Haralick characteristics and classified by Artificial Neural Networks was used. We verified that the improvement of sandpaper granulometry increased the accuracy of species recognition. The developed model based on linear regression achieved a recognition rate of 94% in the training phase, and a post-training recognition rate of 65% for wood treated with 120-grit sandpaper mesh. We concluded that the wood pattern recognition model presented has the potential to correctly identify the wood species studied.

Keywords

Wood Identification, Amazon, Technology, Pattern Recognition, Digital Image Processing, Artificial Neural Networks

Introduction

According to Procópio & Secco ([29]), forest inventory in the Amazon is carried out by traditional people, who identify the trees to be harvested using popular names. Afterwards, these common names are replaced by “probable” scientific names from specialized lists, without considering any scientific, morphological or ecological criteria for species identification.

The use of popular nomenclatures in forest inventories makes the true geographical occurrence of species inconsistent since the vernacular denomination differs according to region, culture or, commercial use ([27]). Noteworthy that the grouping of several species under a single popular name may generate losses of genetic resources and biodiversity of Amazonian species. This also contributes to the sale of high-value species as others not so commonly exploited. When the tree is fallen, the species identification is carried out based on physical, macroscopic, and microscopic wood characteristics. However, professionals in the field of wood identification able to solve these problems are increasingly scarce nowadays.

According to Pedrini & Schwartz ([28]), automated recognition is one of the most complex processes in digital image processing, where information extracted from existing patterns in an image can support the decision-making process. In the literature, several applications have been developed for the botanical identification of species using wood sample images ([36], [11], [33], [35], [15], [18], [16], [7], [1], [12], [24], [21], [34], [37], [22], [26], [8]). However, none of them are focused on Amazonian timber, the main supplier of tropical timber from the Amazon rainforest, or even any other species of Amazon rainforest woods.

Artificial Neural Networks (ANN) are among the most widely applied methods for pattern recognition, providing advanced supervised and unsupervised classification methods. ANN is an artificial intelligence technique based on nonlinear computational models that seeks to reproduce human characteristics, such as learning, association, generalization, and abstraction, being effective in learning patterns from non-linear, incomplete, noise or, composed of contradictory examples ([14]). As an example, Khalid et al. ([18]) used ANN to classify forest species based on more than 1900 images of wood samples of 20 different species from Malaysia.

In this study we aimed to develop a computational tool based on pattern recognition of wood images to support decisions inherent to the identification of timber species commercialized in the Amazon.

Material and methods

Study area

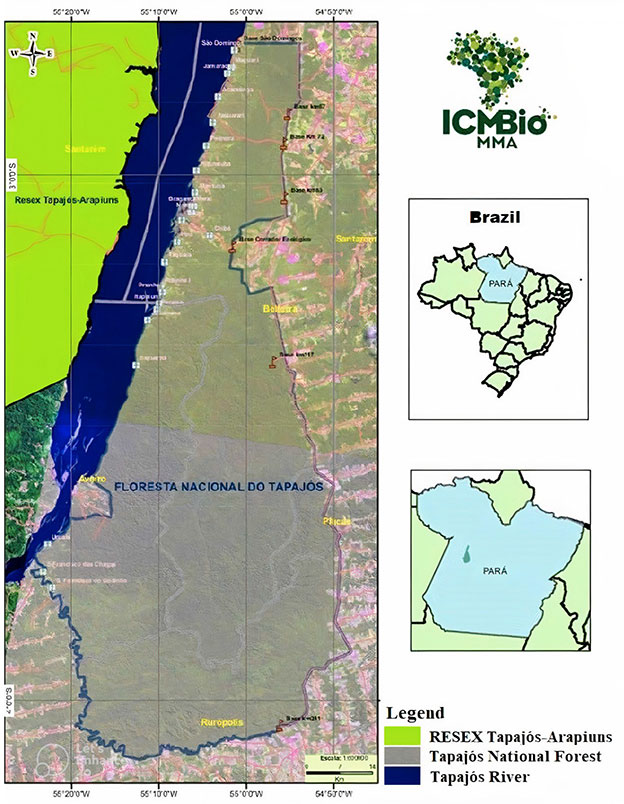

The present study was carried out in the Tapajós National Forest (TNF), a conservation unit (CU) created by the Brazilian Governmental Decree no. 73,684 of February 1974, with an area of approximately 545,000 ha, managed by the Chico Mendes Institute for Biodiversity Conservation (ICMBio). This CU is located near the west boundary of the Pará State, at the counties of Belterra, Aveiro, Rurópolis, and Placas. The area borders are the Tapajós River, the BR 163-Santarém-Cuiabá highway, and the Cupari river.

The botanical identification of timber took place at kilometer 127 of the BR 163 highway Santarém-Cuiabá, where a research base is present and some previous timber identification activities have been carried out during the local forest inventory, thus providing better data for the professionals involved.

The region’s climate is classified by Köppen as AmW (Monsoon type with short dry season), with an average annual temperature of 25 °C, relative humidity of 85% and annual rainfall of 1909 mm, with a dry season between July and November ([10]). The site is situated in a relatively flat area with an elevation between 80 and 180 m a.s.l. ([3], [4]). In the TNF, the vegetation is formed mainly by dense and open ombrophilous rainforests. These forests are composed of a continuous canopy of perennial trees with heights between 25 and 30 m and occasional emergent trees that reach up to 50-60 m height ([4]).

Within the scope of the Tapajós National Forest (Fig. 1), the vegetation types along the Tapajós River have some diverse characteristics, with igapós (blackwater-flooded forests), scrub, rubber, and tall forests. The Tapajós National Forest contains several species of commercial value, such as cedar (Cedrela fissilis), copaiba (Copafeira langsdorfii), rubber tree (Hevea brasiliensis), chestnut (Bertholletia excelsa), among others, distributed over flat reliefs and soft undulations, which are accentuated in the interfluves on the right bank of the Tapajós, south of the Unit of Conservation ([17]).

Fig. 1 - Location of the Tapajós National Forest (adapted from [17]).

Material collection and selection

We made a survey of the timber’s marketed in the state of Pará between 2007 and 2015 ([32]). In addition, twenty samples of each species selected, including Bagassa guianensis (tatajuba), Carapa guianensis (andiroba), Cedrelinga cateniformis (cedrorana), Dipteryx ferrea (cumaru), Goupia glabra (cupiúba), Handroanthus spp. (ipê), Hymenolobium petraeum (angelim), Manilkara spp. (massaranduba), Peltogeny spp. (purple), Vataieropsis sp. (fava), were collected in different sawmills of Rurópolis, State of Pará, Brazil. The samples were 2.5 × 2.5 × 5 cm (w × h × l) specimens. It is noteworthy that woodworking specialists later duly identified each sample.

The specimens were polished using a portable belt sander in the 40, 80, and 120-grit mesh granulometry. In each phase of polishing, images were obtained using a digital microscope equipped with a USB 2.0 megapixel camera (Electronic Magnifier), with the standard magnification of 500×. The image acquired had a resolution of 600 × 600 pixels in the visible spectrum in a sample quadrant measuring 0.5 × 0.5 cm as scale element for the characterization of the wood’s dimensions. For this reason, the distance between the wood sample and the digital microscope in the image capture was approximately 7 cm.

For this study, we also gathered images from a bank of macroscopic wood images collected at the Wood Technology Laboratory of the Federal University of West Pará, Brazil. For ANN training (Tab. 1), 20 images per species were collected, totaling 60 images per polishing method, with an overall total of 480 training images in the whole experiment. For the ANN validation step, some images were used for measuring the accuracy level in the trained ANN. To this purpose, 5 images per species were used, totaling 120 images in the validation experiment; therefore, the overall image bank contained 600 images.

Tab. 1 - Number of wood samples analyzed in this study, according to the three different polishing methods (treatments).

| Treatment | Species | Training | Validation | ||

|---|---|---|---|---|---|

| By species | Total | By species | Total | ||

| Sandpaper 40 | 8 | 20 | 160 | 5 | 40 |

| Sandpaper 80 | 8 | 20 | 160 | 5 | 40 |

| Sandpaper 120 | 8 | 20 | 160 | 5 | 40 |

| Total | - | 60 | 480 | 15 | 120 |

Software development

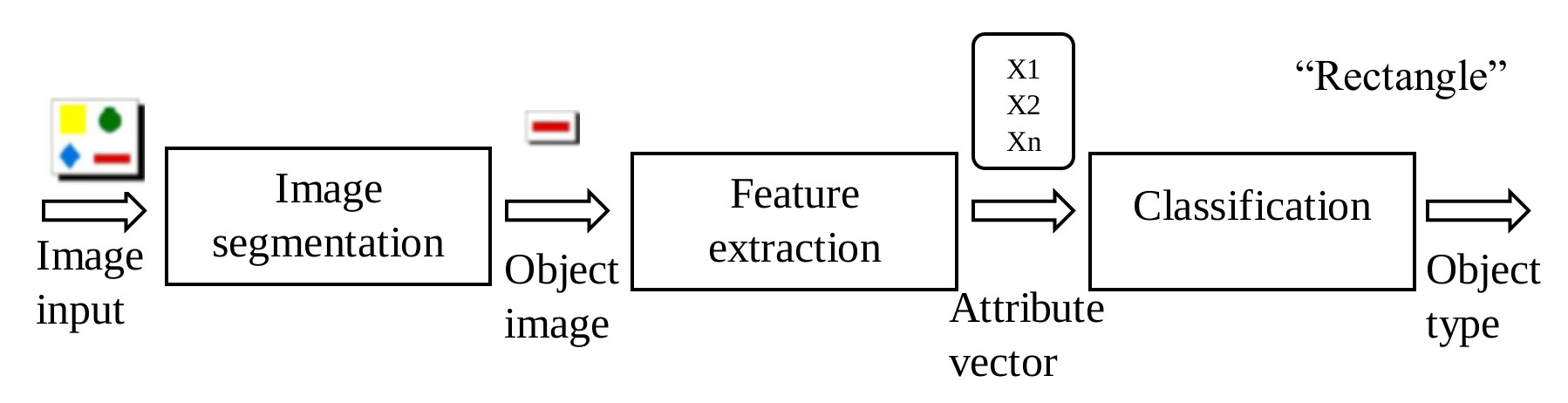

The pattern recognition of images from treated wood samples was subdivided in three steps, according to the methodology developed by Bishop ([2]) and Castleman ([5]): image segmentation, feature extraction, and classification, the latter being the recognition itself (Fig. 2). Any useless information in image segmentation that could make recognition work difficult was discarded. In the extraction of characteristics, the objects to be recognized were removed for further classification.

Fig. 2 - The three phases of digital images source pattern recognition (adapted from [5]).

For the segmentation step, we adopted a routine image processing with texturing segmentation based on the co-occurrence of the grayscale matrix.

Regarding the characteristic extraction step, we followed the recommendations of Haralick et al. ([13]) who suggested to calculate the attributes of co-occurrence matrices by counting the shades of gray in the image. This serves a measure to different textures that do not follow a certain pattern of repeatability, providing relevant information for their classification. Haralick’s characteristics are: homogeneity, maximum probability, entropy, a moment of difference of order k, an inverse moment of difference of order k, an inverse variance, energy, contrast, variance, correlation, among other descriptors.

There are several diverse neural paradigms ([23]) with different structure, training procedure, and capabilities. For example, the network may be trained in either a supervised ([30]) or unsupervised way ([19]). The choice of the particular neural network model depends on the application goals and requirements. Here, we chose the multilayer perceptron (MLP) approach to perform the recognition task. The main advantage of the MLP is the creation of clustering shapes that are highly nonlinear. MLP with two hidden layers are capable of forming arbitrary decision regions between classes ([23]). These decision regions can be as smooth as required by using the proper number of hidden nodes in each layer. Furthermore, it has been proven by Gish ([9]) that minimizing the mean square error by means of the backpropagation algorithm results in an approximation of the class posterior probabilities.

Regarding the classification or pattern recognition stage, we used the Artificial Neural Networks by the Multilayer Perceptron technique (MLP), with the backpropagation supervised training algorithm. Using this algorithm, the learning step is performed in two phases. In the first one (forward) the output values of the network are calculated from the input values supplied. In the second one (backward) the weights associated with each connection are updated according to the differences between the obtained output values and the desired values.

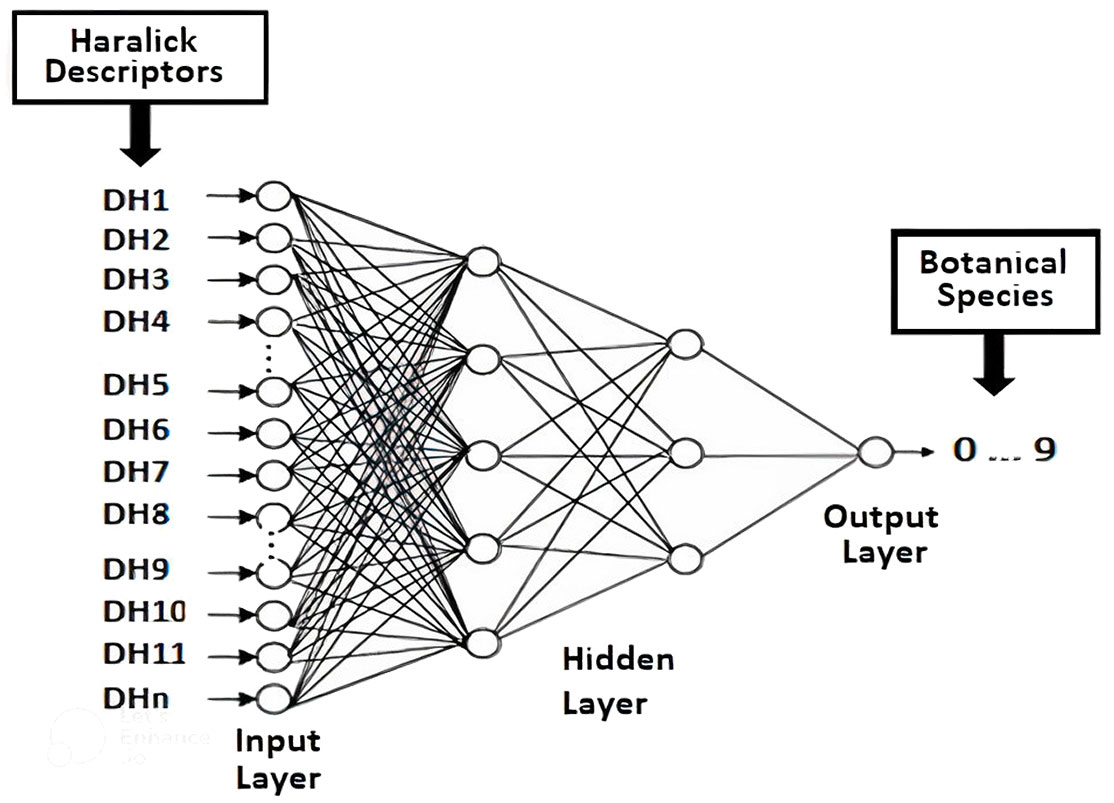

The ANN architecture developed (Fig. 3) includes input parameters which refer to an image composed of Haralick’s texture descriptors. The values obtained in the segmentation step permeate through the hidden layer with neuronal synapses resulting in a standardization structure, which allow to recognize the botanical species of the analyzed wood samples through these groups’ values. Next, supervised learning occurs with evidence that the standardization refers to species of the specific taxon, which in this case is represented by a value ranging from 0 to 9.

Fig. 3 - The ANN architecture developed in this study for the identification of Amazon wood species.

The method applied was repeated for each of the three tested treatments (images sanded by 40, 80, and 120-grit) in terms of image segmentation (co-occurrence matrix), characteristic extraction (Haralick descriptors), and pattern recognition (ANN classification).

In the training step of ANN, the linear regression was used, defined as an equation estimating the conditional (expected value) of a variable y, given the values of some other variables x ([31]). Thus, we presents the linear regression graphs including the scatterplots of observed data, to better illustrate their dispersion and evaluate the model performances in pattern recognition in the ANN training phase.

For the pattern recognition analysis, the images not used in training were submitted to the ANN model (verification step). The ANN model performance was assessed by comparing them with the results inferred by the specialists on the same samples, and the model recognition rate was evaluated as the percentage of images correctly identified by the ANN model, i.e., matching the species identification provided by wood specialists.

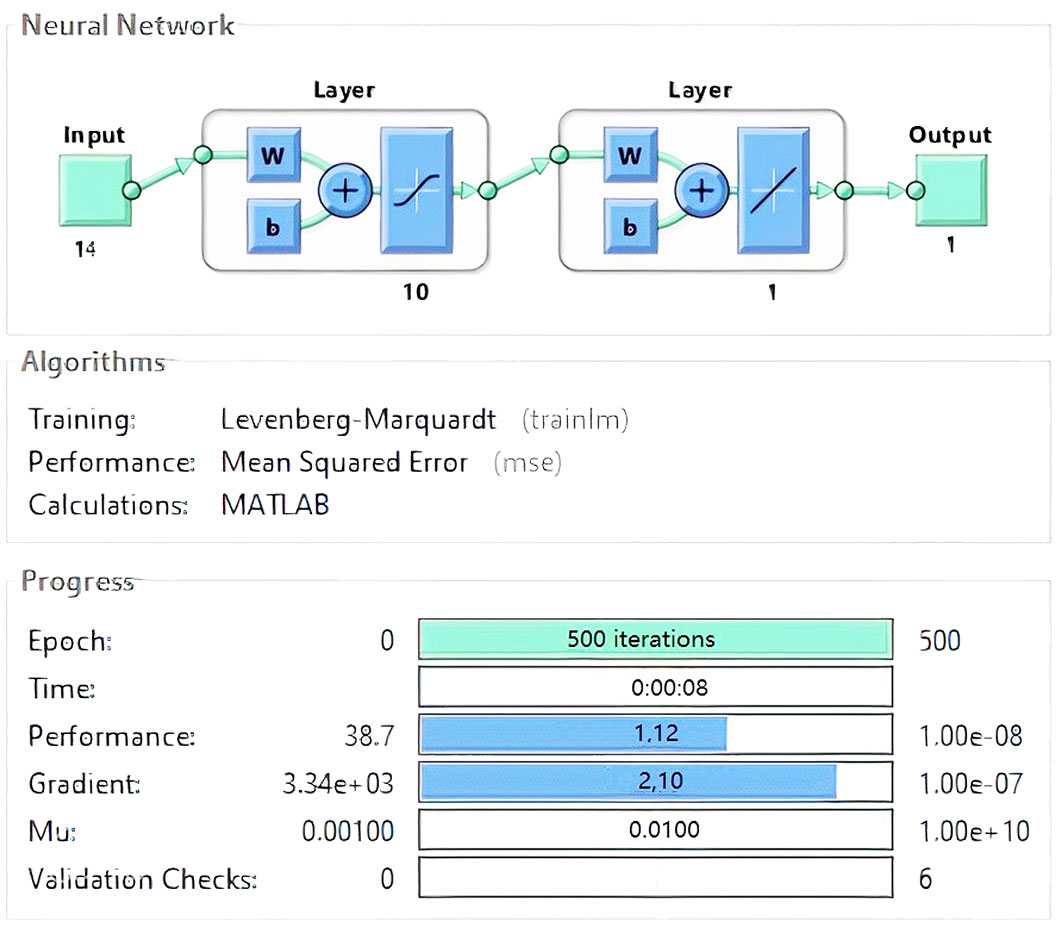

The architecture of the ANN developed in this study had ten neurons in the hidden layer (Fig. 4), providing greater adequacy in pattern recognition. The number of epochs is defined as the number of times (cycles) the learning algorithm works through the entire training dataset. The configuration of the developed ANN had 500 epochs for training with exhibition every 50 epochs. The higher and lower values were applied as tests, however, such values were paired for a satisfactory result. The maximum error rate of the model was set to 0.000000001, and the training algorithm was optimized using the Levenberg-Marquardt method ([20], [25])

Results

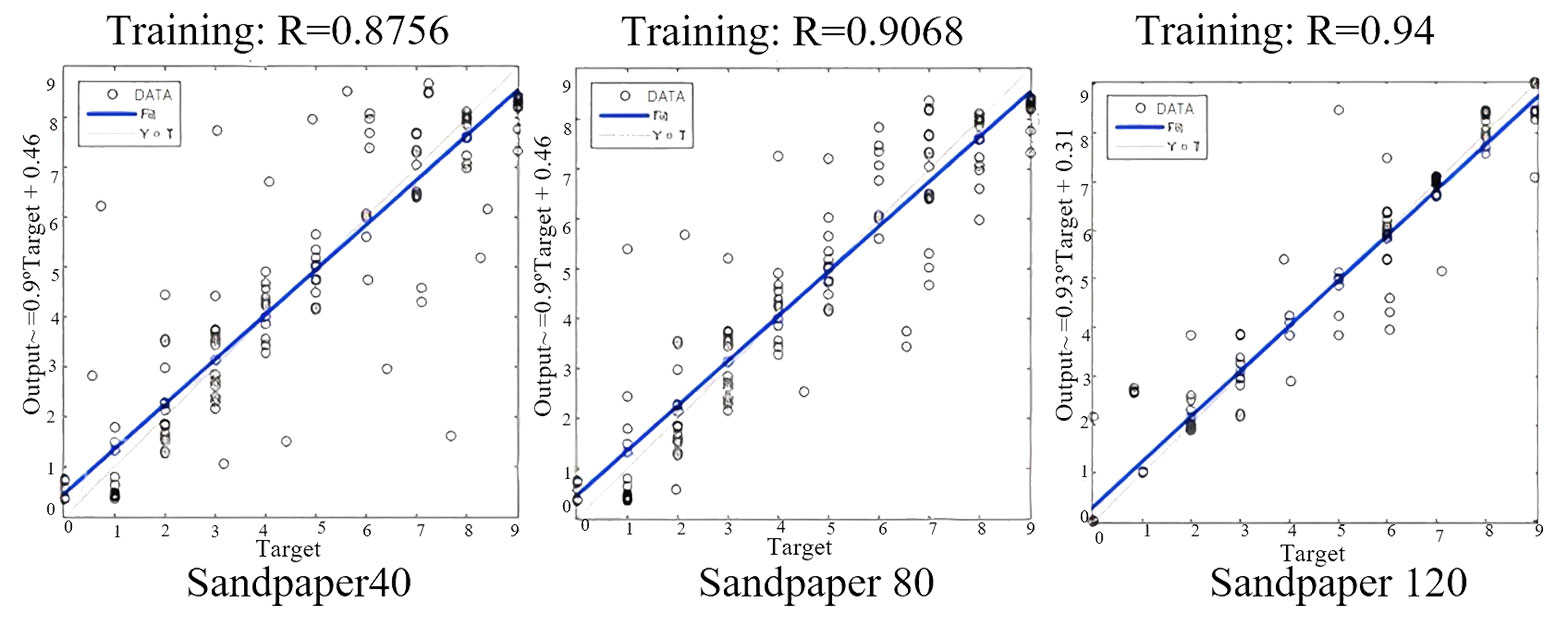

The analysis of ANN performances in the training step allowed to verify the dispersal of the results obtained by the model in term of pattern recognition (Fig. 5). The wood samples treated with 120-grit mesh sandpaper showed a lower dispersion of pattern recognition results (Fig. 5c). In this graph, the y-axis represents the segmented image data outputs after applying the neural network. The regression analysis indicated that the increase in sandpaper granulometry used for polishing wood sample surface resulted in a greater accuracy of wood species recognition using the ANN model developed.

Fig. 5 - Performances of the ANN model (training phase) for the different treatments (wood sample surface treated with 40-, 80-, and 120-grit mesh sandpaper).

The ANN training stage is a critical step in the model development, as at this stage the specialist’s knowledge is transferred to the recognition system. In order to evaluate the model performances in wood species recognition using sample images, it was necessary to carefully analyze the ANN behavior in this phase.

After the ANN training, the recognition performance was 87%, 90% and 94% for the treatments in 40, 80 and 120-grit mesh treatments, respectively (Fig. 5).

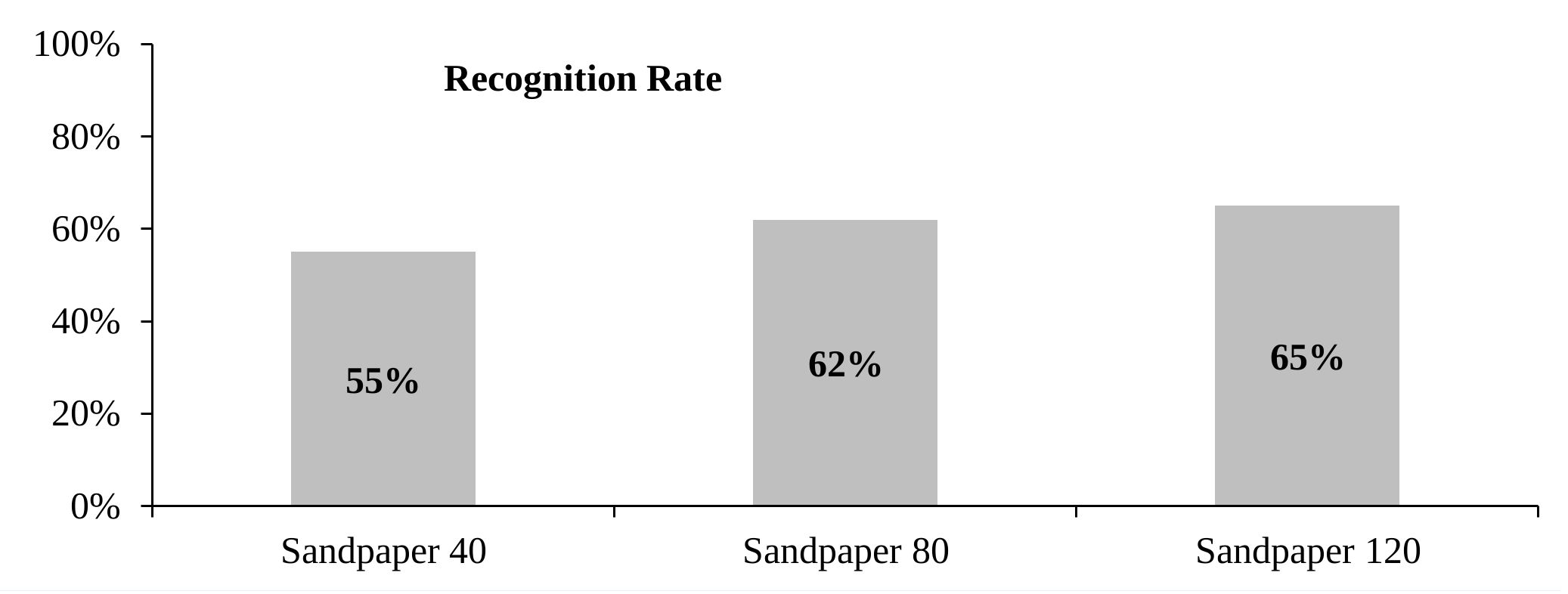

The results from the ANN model developed using pattern recognition analysis of wood images allowed to identify the botanical species with fairly high accuracy - 55%, 62%, and 65% for the treatments of 40, 80 and 120 mesh, respectively (Fig. 6).

Fig. 6 - Results of the different recognition rate obtained using the ANN model (validation step) for the different treatments (wood sample surface polished with 40-, 80-, and 120-grit mesh sandpaper).

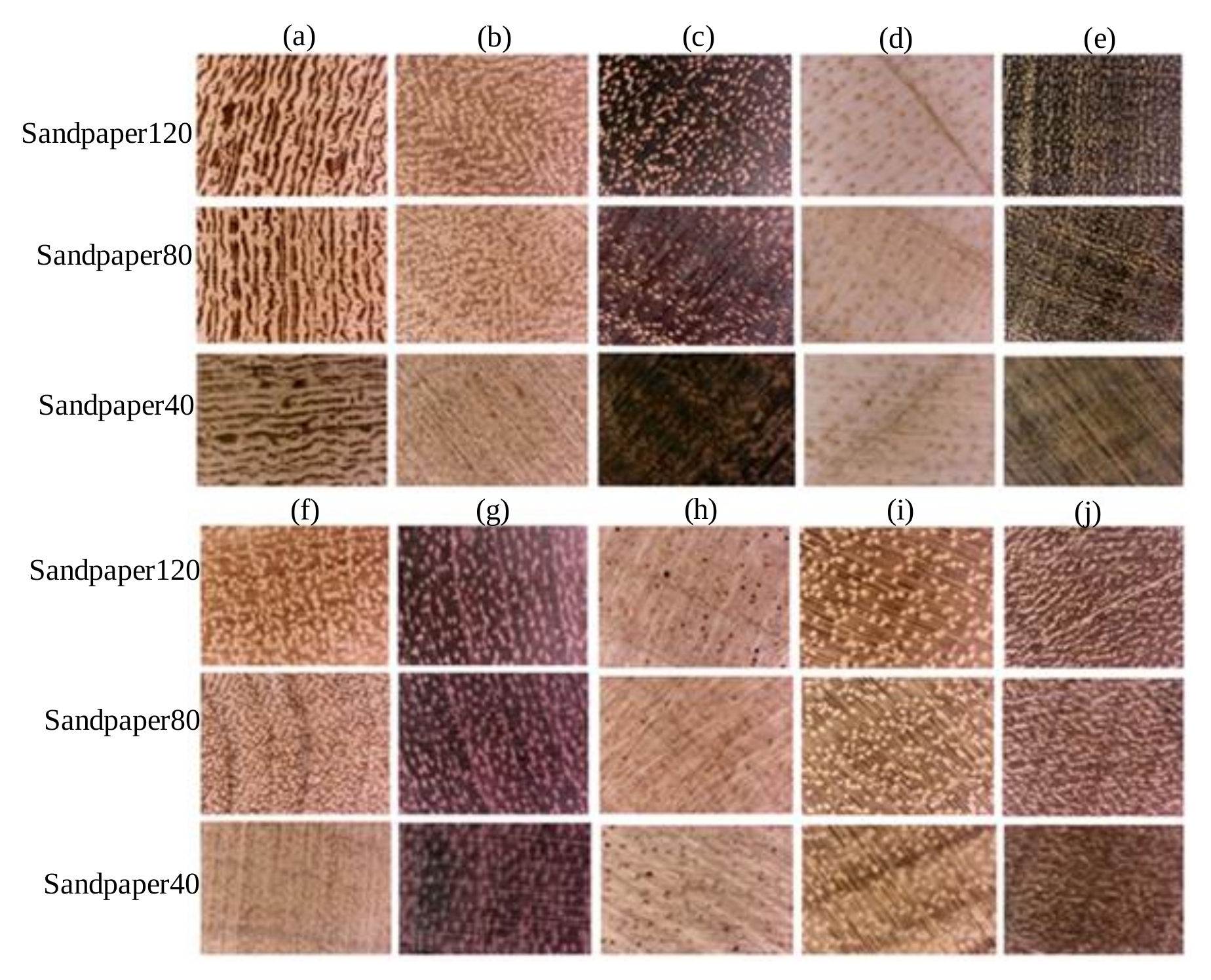

The 40, 80, and 120-grit sandpaper treatment caused a gradual gain in the removal of external characteristics such as grooves, defects, ripples, and marks from the wood cutting (Fig. 7). Further, we recorded an increase in surface clarity, and brightness, which affect the model performance in terms of extraction of characteristics for anatomical identification of the wood samples.

Fig. 7 - Macroscopic images of Amazonian wood samples (a-j), grouped by treatment (wood sample surface treated with 40-, 80-, and 120-grit mesh sandpaper).

We observed a satisfactory recognition rate in the three experiments during the validation step, proving the recognition ability of the model used. Moreover, we recorded that the refinement of wood surface by sandpaper treatment increases the recognition rate of wood species.

Discussion

The image acquisition process impacts any structure of the pattern recognition system. The image of wood samples as the main focus of the system may present varying characteristics, according to the technology used for its capture. In our study, macroscopic images of wood species were used for pattern recognition ([36], [11], [33], [35], [18], [16], [6], [7], [8]).

Image segmentation is the key stage of digital processing, since the recognition of the image obtained is based on the segmented image. According to Haralick et al. ([13]), the texture patterns found in wood images are characterized by spatial distribution, luminosity and structural arrangement of the surface in relation to the neighboring regions. The Haralick descriptors were used in this study for assessing the representativity of the texture in each wood species, as previously reported by Hang Jun & Bihui ([12]), Bi-Hui et al. ([1]) and Tou et al. ([35]).

When analyzing the differences among sandpaper treatments applied to wood samples surfaces by mechanical devices, we observed that the stronger is the surface treatment, the higher is the gain in pattern recognition, thus reducing the computational artifacts during the image segmentation stage. After the sandpaper application process, several improvements of the image were evident.

The 40-grit sandpaper application resulted in the removal of grooves, undulations, and defects due to the equipment used to cut the wood (Fig. 7). The wood surface became more homogeneous as regards the relief of the image capture zone. Despite this, the wood’s anatomical characteristics appeared inconspicuous or imperceptible even under a microscope in terms of the methodological standards followed in this study.

The 80-grit sandpaper application (Fig. 7) aimed to clean the viewing surface, removing small defects such as groove lines, thus making the wood surface’s characteristics more evident and increasing the sharpness of the captured image. Nonetheless, the captured image still showed a lack of brightness of the surface with opaque and slightly rough properties.

The 120-grit sandpaper had the purpose of finishing, aiming at the removal of any defects that still remain on the surface after 80-grit sandpaper, thus increasing the degree of sharpness and consequently the perception of the wood’s anatomical characteristics. This treatment favored the surface polishing, which is reflected by the increase in brightness and luminosity of the image obtained from wood samples (Fig. 7). Other surface treatment techniques may be applied, such as microtome planing or polishing with increasing granulometry up to 1200 mesh.

The lack of infrastructure and energy in some areas of the Amazonian roads makes it difficult to inspect and monitor wood loads. In this context, the methodology adopted in this study involved an energy generator which made the use of three belt sanders possible, as well as a digital magnifying glass and the recognition system properly installed on a laptop or mobile phone.

The results of recognition rate represents the balance between the quantity and relevance of the abstracted image characteristics, and the ability of the classification method to effectively recognize the standards. Previous studies focused on recognition patterns in wood images, showing differences as to the form of segmentation, extraction of characteristics, classification as well as objectives, scope, and application focus for different forest regions. The results of the above studies were fairly different and not always fully satisfactory, with a recognition rate ranging from 60% ([35]) to 65% ([8]), 80.9% ([7]), 88% ([36]), 91.7% ([1]), 93.3% ([21]) up to 95% ([18]).

Among the most applied methods in the above-mentioned studies, ANNs stand out because of their range of applicability and the possibility to apply both supervised and unsupervised classification. The highest accuracy in results using ANNs was attained by Khalid et al. ([18]), who analyzed more than 1900 wood images of 20 different forest species from Malaysia using an industrial standard and high-performance camera (JAI CV-M50) and a LED array developed ad-hoc for lighting. The higher recognition rate reported in their study (95%) compared to our analysis (65%) may be due to the larger amount of images analyzed (95 vs. 60 image per species, respectively) in the ANN learning process. However, Khalid et al. ([18]) do not present any mechanical intervention on sample woods (i.e., the treatment with mesh sandpaper) as it was applied in this work, which we proved to significantly increase the accuracy in pattern recognition. Moreover, we hypothesized that if the wood sanding method were applied in the study of Khalid et al. ([18]), the results obtained would be further improved.

The recognition rate of wood samples found in this study (65%) is similar to that reported from similar studies in the literature, and fairly satisfactory for the identification of the botanical species from images taken from wood samples. However, the presented method needs improvements to increase the final accuracy. To that end, it is necessary to enhance the pattern recognition process, with possible incremental extraction of characteristics and other classification techniques, and the inclusion of attributes derived from color and geometry ([18], [1], [21]).

Conclusions

The pattern recognition system used in this study allowed for the identification of woods from the Amazon. The better the polishing of wood surface, the easier the recognition of the wood species. The ANN model developed in this study based on linear regression reached a recognition rate >90% in the training phase. Further, the recognition rate in the validation stage was >60% after polishing the wood surface with 120 grit sandpaper mesh.

We suggest the use of textural segmentation associated with Haralick’s features to wood classification by artificial neural networks for the following Amazon species: Bagassa guianensis (tatajuba), Carapa guianensis (andiroba), Cedrelinga cateniformis (cedrorana), Dipteryx ferrea (cumaru), Goupia glabra (cupiúba), Handroanthus spp. (Ipê), Hymenolobium petraeum (angelim), Manilkara spp. (massaranduba), Peltogeny spp. (Purple), Vataieropsis spp. (fava). However, other variables could be included in the image segmentation process to increase the accuracy of the result.

These findings will contribute to the inspection, monitoring, and classification of wood loads in the Amazon, simplifying the identification of species through artificial neural networks.

Conflicts of interest

The authors declare no conflicts of interest.

References

Gscholar

CrossRef | Gscholar

Gscholar

Online | Gscholar

Gscholar

Gscholar

Gscholar

CrossRef | Gscholar

Gscholar

CrossRef | Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Authors’ Info

Authors’ Affiliation

Márcio José Moutinho da Ponte 0000-0002-0724-3721

Victor Hugo Pereira Moutinho 0000-0001-7770-3087

Celson Pantoja Lima 0000-0002-8074-8566

Graduate Program in Intellectual Property and Information Transfer Technology for Innovation/Federal University of West Pará (Brazil)

Ricardo Jardim-Gonçalves 0000-0002-3703-6854

Universidade Nova de Lisboa (Portugal)

Massachusetts Institute of Technology, MA (United States of America)

Corresponding author

Paper Info

Citation

de Souza Vieira GL, Moutinho da Ponte MJ, Pereira Moutinho VH, Jardim-Gonçalves R, Pantoja Lima C, de Albuquerque Vinagre MV (2022). Identification of wood from the Amazon by characteristics of Haralick and Neural Network: image segmentation and polishing of the surface. iForest 15: 234-239. - doi: 10.3832/ifor3906-015

Academic Editor

Giacomo Goli

Paper history

Received: Jun 19, 2021

Accepted: May 06, 2022

First online: Jul 14, 2022

Publication Date: Aug 31, 2022

Publication Time: 2.30 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2022

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 30134

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 25944

Abstract Page Views: 2298

PDF Downloads: 1401

Citation/Reference Downloads: 5

XML Downloads: 486

Web Metrics

Days since publication: 1298

Overall contacts: 30134

Avg. contacts per week: 162.51

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

Total number of cites (since 2022): 1

Average cites per year: 0.25

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Research Articles

NIR-based models for estimating selected physical and chemical wood properties from fast-growing plantations

vol. 15, pp. 372-380 (online: 05 October 2022)

Research Articles

Mechanical and physical properties of Cunninghamia lanceolata wood decayed by brown rot

vol. 12, pp. 317-322 (online: 06 June 2019)

Research Articles

Changes in moisture exclusion efficiency and crystallinity of thermally modified wood with aging

vol. 12, pp. 92-97 (online: 24 January 2019)

Research Articles

Study on the chemical composition of teak wood extracts in different organic solvents

vol. 14, pp. 329-336 (online: 09 July 2021)

Research Articles

Characterization of VOC emission profile of different wood species during moisture cycles

vol. 10, pp. 576-584 (online: 08 May 2017)

Research Articles

Examining the evolution and convergence of wood modification and environmental impact assessment in research

vol. 10, pp. 879-885 (online: 06 November 2017)

Research Articles

Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal

vol. 10, pp. 669-679 (online: 11 July 2017)

Research Articles

The potential of using xylarium wood samples for wood density calculations: a comparison of approaches for volume measurement

vol. 4, pp. 150-159 (online: 11 August 2011)

Research Articles

Analysis of factors influencing deployment of fire suppression resources in Spain using artificial neural networks

vol. 9, pp. 138-145 (online: 19 July 2015)

Research Articles

Improving dimensional stability of Populus cathayana wood by suberin monomers with heat treatment

vol. 14, pp. 313-319 (online: 01 July 2021)

iForest Database Search

Google Scholar Search

Citing Articles

Search By Author

- GL de Souza Vieira

- MJ Moutinho da Ponte

- VH Pereira Moutinho

- R Jardim-Gonçalves

- C Pantoja Lima

- MV de Albuquerque Vinagre

Search By Keywords