Improving sustainability in wood coating: testing lignin and cellulose nanocrystals as additives to commercial acrylic wood coatings for bio-building

iForest - Biogeosciences and Forestry, Volume 14, Issue 6, Pages 499-507 (2021)

doi: https://doi.org/10.3832/ifor3782-014

Published: Nov 11, 2021 - Copyright © 2021 SISEF

Research Articles

Collection/Special Issue: Research Project PRIN-MIUR 2015

The forest-wood value chain: biomass supply, traceability, C-footprint. Innovation for bioarchitecture and energy efficiency

Guest Editors: Scarascia Mugnozza G, Maesano M, Romagnoli M

Abstract

Wood use in bio-building should be considered as one of the main pillars of sustainability. According to international standards, beech wood (Fagus sylvatica L.) is a rather less durable species as it is subject to degradation due to weathering, though it is abundantly available to a more intense use. Service life of beech products and wood products in general can be enhanced by different methods, such as heat treatments, but new chances are offered by coating technologies. However, to ensure protection from wood-destroying organisms, most commercial coatings include components that could harm human health, other organisms and the environment. Therefore, coating industry has to develop more eco-friendly solutions in order to decrease its impact on human health and environment. The objective of this article was to modify commercial acrylic varnish by adding cellulose nanocrystals (CNC) and lignin (LN) extracted from beech wood and investigate their effect on water sorption, additive dispersion in the coating matrix and coating resistance to bacterial attack. Contact angle, weight gain and colour difference were analysed and FT-IR mapping was applied. The performance of CNC was promising, as it enhanced water sorption of the modified coating. However, protection against bacterial attack was not satisfying. On the other hand, chemically unmodified lignin did not show positive effects as component in the coating formulation. Nevertheless, the currently limited usage of these two renewable and abundant resources urgently calls for their more efficient utilization, in order to create additional value with industry side-streams producing novel bio-based materials. Further experiments are needed in order to obtain better dispersion of the particles and higher resistance to bacterial attacks.

Keywords

Acrylic Waterborne Coating, Beech Wood, Fagus sylvatica, Lignin, Cellulose Nanocrystal (CNC), FT-IR Mapping, Antibacterial Activity

Introduction

Utilization of wood in bio-building could be considered as one of the main pillars of sustainable construction. Yet, the full exploitation of wood as a construction material still requires some weak points to be solved. Indeed, the risk of degradation caused by weathering and biotic attacks is currently the most limiting factor. Moreover, several mechanical properties of wood are lower compared to synthetic and not-renewable materials. A further important concept towards a more sustainable approach is the use of wood from short supply chains ([6], [29]), but so far it has been mainly applied to biomass production for energy purposes ([8], [22]). Nevertheless, recent findings on the use of non-durable wood, such as beech and Corsican pine, in bio-building applications were fairly promising ([4], [33]). According to UNI-EN-350 ([37]), beech has less durable wood as it is susceptible to degradation by weathering. The service life of beech products must be addressed especially when used in the most severe conditions (i.e., risk class 4, according to [36]). Increasing the durability of beech wood by sustainable methods is still one of the major challenges. To this aim, the successful use of physical methods such as heat treatments ([6], [28]) have been recently reported, but the novel and greener generation of wood coatings offer new interesting opportunities. Coating technology provides surface protection, decorative finishes and numerous special functions for commodities. To ensure protection from wood-destroying organisms, coatings are often composed of synthetic compounds with biocidal functions ([46]) that were proved to be harmful for human health. Many attempts were carried out to replace fossil-based components of coatings with natural compounds ([35]), but still much work is required for their industrial use in high-technology applications. Currently, a reasonable compromise is the addiction of natural compounds to commercial coatings which can maintain or even increase their performances. Among the bio-based additives which could be successfully used in wood industry, lignin and cellulose-based compounds are the most sustainable in terms of circular economy ([19], [45], [43]). Several studies demonstrated that lignin, due to its antioxidant properties, increases the natural decay resistance of wood and the performance of coating in outdoor conditions. To this purpose, promising results were obtained using Kraft lignin ([5], [35]), Organosolv ([10]) and Acidolysis lignin ([35]). The performance of lignin as coating component largely depends on its source, the method of extraction, and its application to the woody substrate. So far, all the tests have been carried out in the laboratory, showing promising performances ([16], [45], [43]). Indeed, several properties of lignin, such as low toxicity, biodegradability, low cost and high availability ([1]), make it a very promising candidate as an additive to synthetic or inorganic materials for wood coatings. Other promising compounds for coating industry are cellulose nanocrystals (CNC). Vardanyan et al. ([40]) reported that the addition of CNC to wood coatings did not lower their colour stability and increased weathering performance of the varnished wood surface. Furthermore, multifunctional coatings have been recently developed for wood-based composites or CNC-coating of glass fibres for fibre-reinforced composites ([13]). CNC also represent a promising component for the development of innovative reinforced wood adhesives, due to their high strength and low weight ([19]). Among the commercial coatings, waterborne synthetic acrylic varnishes are one of the most used for both indoor and outdoor applications. They show high transparency and good UV-resistance, but they do not penetrate wood as deep as oils do. Their main advantage is their resistance to yellowing, but photostability needs to be increased to improve their suitability, e.g., for window frames ([39], [26], [2]).

The main objective of this study is to investigate the effect of CNC and beech lignin added to commercial acrylic varnish on colour change, wettability and resistance to bacterial attack. Antibacterial activity was investigated considering a product end use as kitchen tops in contact with food or children’s toys, where contact with the mouth cannot be excluded. The selected support was beech wood (Fagus sylvatica L.) which is the most promising species for innovative bio-building applications and the most sustainable thanks to its short supply chain, being widely spread all across Europe.

Materials and methods

Material

Flat-grained beech wood samples 10 × 10 × 3 mm (L×T×R) were taken in tangential direction from one board cut, which was dried in an industrial dry kiln. Wood samples were conditioned in the lab at about 65% relative humidity (RH) and 21 °C for one year. Just before coating, the wood samples were sanded with 120 grit sandpaper and wiped clean before measuring the contact angle of the coating.

A commercial water-borne acrylic coating provided by the company Finedin S.r.l. (Taviano, LE, Italy) was applied onto samples. This transparent coating is based on poly (methyl acrylate/methyl methacrylate/butyl acrylate), copolymer dispersion; its solid content is 34%, viscosity is 40-50" F/4, and gloss at 60° is 75-85, while the pH was 8.5. The main function is the protection of wood against impacts and scratches in indoor and outdoor conditions. In the commercial formulation some additives (antimold compounds) were present.

Commercial acrylic coating was modified with CNC (chemically: cellulose hydrogen sulphate sodium salt) that were purchased from CelluForce Inc. (Montreal, QC, Canada). The spray-dried CNC powder has bulk density of 0.7 g m-3, moisture content of 4-6% and particle size spanning from 1 to 50 μm. CNC crystallites (particle diameter: 2.3-4.5 nm, particle length: 44-108 nm) have a hydrodynamic diameter of 70 nm ([19]).

Acrylic coating was also mixed with lignin, which was kindly provided by Fraunhofer Center for Chemical-Biotechnological Processes CBP (Leuna, Germany). The lignin was extracted from residues of beech wood using an Organosolv process with ethanol-water as solvent ([32]).

Methods

The different formulations of Acrylic coating (Av) mixed together with CNC and lignin are summarized in Tab. 1. Lignin and CNC were added also to pure water as additional control samples. The experimental plan is summarized in Fig. S1 (Supplementary material).

Tab. 1 - Formulation of acrylic- and water-based coatings and corresponding abbreviation in the text. (Av): Acrylic varnish; (CNC): Cellulose nanocrystals (LN): lignin (W): Water.

| Code | Formulation |

|---|---|

| Av | Commercial water-based acrylic coating |

| Av-2CNC | Commercial water-based coating plus cellulose nanocrystals (2%) |

| Av-2LN | Commercial water-based acrylic coating plus lignin powder (2%) |

| Av-5CNC | Commercial water-based acrylic coating plus cellulose nanocrystals (5%) |

| Av-5LN | Commercial water-based acrylic coating plus lignin powder (5%) |

| W-2CNC | Distilled water plus cellulose nanocrystals (5%) |

| W-2LN | Distilled water plus lignin powder (2%) |

| W-5CNC | Distilled water plus cellulose nanocrystals (5%) |

| W-5LN | Distilled water plus lignin powder (5%) |

Samples were dip-coated for 5 minutes with each formulation and then left to open drying at room temperature for one week.

Colour measurement

Digital images of the samples were taken using an HP Scanjet 4800 scanner, in order to analyze their CIELAB colour space and coordinates using the open-source graphics software GNU Image Manipulation Program (GIMP v. 2.10.12). According to UNI-EN-ISO/CIE-11664-4 ([38]), three different spots per sample were selected and twelve samples per coating formulation were analyzed. The coordinates a*, b* and the lightness L* were measured on the tangential plane. The total colour difference (ΔE*) represents the difference in colour between virgin wood and the samples coated with commercial acrylic varnish and with the modified formulations, respectively. ΔE* was calculated according to the following formula (eqn. 1):

Weight and thickness

Weight of the samples was measured using an electronic analytical scale (model JA503, Jing xin, China). Samples were weighted before coating and after the drying period of one week (168 h). For determination of coating thickness, the coating layer was measured using a stereomicroscope (model MZ 16A, Leica Microsystems AG, Wetzlar, Germany) at micron level. Twelve samples per formulation were weighted. A representative sample was cut in half and then the thickness of the coating layer was measured on three spots per sample.

Surface wettability test

Wetting analysis was executed at room temperature. A small droplet (4 μl) of distilled water was taken with a micropipette and dropped on the wood surface (tangential plane). The images were taken immediately after the drop was released and further until complete spreading using a camera (Coolpix® P7700, Nikon, Tokyo, Japan). Time intervals varied among groups. Contact angle was measured on every picture taken on two sides of the drop using GIMP software. Final contact angle was calculated as an average of both sides of the droplets to compensate for sample surface variations. The time needed until complete surface wetting was recorded. One control and one representative sample per coating formulation were chosen for contact angle measurement.

Antibacterial activity test

The antibacterial test was made using the bacteria-inhibiting ring method (agar plate diffusion test, as described in [11]). Pseudomonas aeruginosa (gram-negative) was used to evaluate the antimicrobial activity. P. aeruginosa is an opportunistic bacterial pathogen with ecological relevance in bioremediation. This species is ubiquitous in nosocomial environment and widely diffused in water and soil. It exhibits also relevant phenotypic traits in biocontrol and in sessile growth (i.e., biofilm formation on material - [34]). We used an environmental isolate, P. aeruginosa strain AP02-1, that is able to degrade crude oil and byproducts was used ([23]).

Two parallel tests were performed. In the first test, a 20 μl drop of each coating formulation was spotted on cetrimide agar plates, which were previously inoculated with bacterial suspension (~ 1.5 × 105 CFU ml-¹ diluted in salt solution from ON liquid culture). In the second part of the experiment, one representative wood sample for each formulation was placed on an agar plate with the same amount of bacterial suspension. In this case, the selected groups were the highest percentages of CNC and lignin with both Av and W as matrix. The chosen formulations were compared with virgin wood as control sample.

Cetrimide agar (CET 45.5 g l-1 - Merck, USA) plus 10 ml l-1 of glycerol is the selective growth media for P. aeruginosa that was used to avoid the growth of microbial cells accidentally introduced with the coating or the wood samples that were not subjected to prior sterilization. After inoculation, the CET plates were incubated at 37 °C.

FTIR spectroscopy and mapping analysis

Samples of the coating formulations and coated wood samples were analyzed with a FTIR-4100® Fourier Transform Infrared spectrometer (Jasco Corp., MD, USA) in the range of 2000-1000 cm-1. One representative sample from each group was analyzed in absorbance mode within a surface of 50×50 μm, using a Jasco IRT-7000® Irtron Infrared microscope. The number of scans was 500.

Statistical analysis

Statistical analyses were carried out with Minitab® Statistical software v. 18.1 (Minitab Inc., State College, PA, USA) to determine the effect of lignin and cellulose addition to the acrylic coating. The differences between the various coating modifications were subjected to principal component analysis (PCA), considering the colour and weight change between virgin wood and treated wood. For the colour variation 3 spots × 12 samples × 9 formulations were analyzed for a total of 324 replicates. Weight data included 1 measurement for each sample × 12 samples × 9 formulations, totalling 108 replicates.

Results

Colour measurement

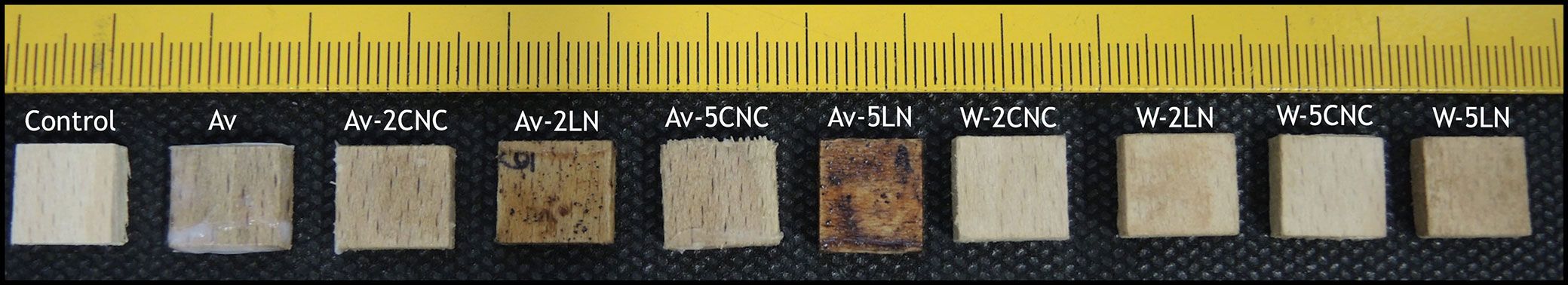

In Fig. 1 the wood samples treated with the different coating formulations are shown.

Fig. 1 - Samples treated with different formulations based on acrylic coating (Av) mixed with CNC and LN, as well as control samples treated with water mixed with CNC and LN, respectively. For sample labels, see Tab. 1.

In Tab. 2 the mean values of the determined CIELAB colour coordinates with the corresponding ΔE* values for the samples before and after dip-coating are reported.

Tab. 2 - CIELAB coordinates mean values (± standard deviation) of virgin wood and treated wood before and after dip coating, respectively, and corresponding ΔE* values.

| Treatment | Before dip-coating | After dip-coating | ΔE* | ||||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | ||

| Av | 86.1 ± 2.6 | 2.5 ± 0.6 | 14.3 ± 1.2 | 79.0 ± 4.4 | 6.0 ± 0.8 | 20.4 ± 0.9 | 10.30 ± 3.48 |

| Av-2CNC | 82.4 ± 5.4 | 2.7 ± 0.8 | 12.0 ± 1.4 | 78.4 ± 5.7 | 5.3 ± 1.0 | 18.3 ± 0.8 | 8.76 ± 2.91 |

| Av-2LN | 83.9 ± 6.7 | 2.4 ± 0.9 | 12.3 ± 1.0 | 48.6 ± 14.0 | 6.8 ± 1.8 | 18.0 ± 5.1 | 37.06 ± 15.24 |

| Av-5CNC | 84.1 ± 6.2 | 2.5 ± 0.9 | 12.5 ± 1.3 | 80.5 ± 7.5 | 5.3 ± 1.2 | 18.3 ± 0.9 | 7.93 ± 2.53 |

| Av-5LN | 86.0 ± 2.8 | 2.0 ± 0.5 | 13.1 ± 1.1 | 27.1 ± 11.0 | 5.3 ± 2.5 | 9.8 ± 5.0 | 59.37 ± 11.38 |

| W-2CNC | 85.7 ± 6.3 | 2.3 ± 0.9 | 12.9 ± 1.6 | 86.5 ± 4.6 | 2.6 ± 0.8 | 14.0 ± 1.2 | 3.64 ± 3.62 |

| W-2LN | 84.5 ±4.4 | 2.2 ± 0.7 | 11.7 ± 0.9 | 78.5 ± 7.5 | 6.0 ± 1.4 | 18.3 ± 1.1 | 11.05 ± 5.69 |

| W-5CNC | 84.5 ± 5.0 | 2.2 ± 0.8 | 13.1 ± 0.9 | 85.9 ± 4.6 | 2.1 ± 0.9 | 13.8 ± 0.9 | 3.04 ± 1.87 |

| W-5LN | 87.4 ± 3.7 | 2.1 ± 0.7 | 13.3 ± 1.0 | 69.4 ± 7.8 | 8.1 ± 1.3 | 20.3 ± 1.1 | 20.71 ± 6.54 |

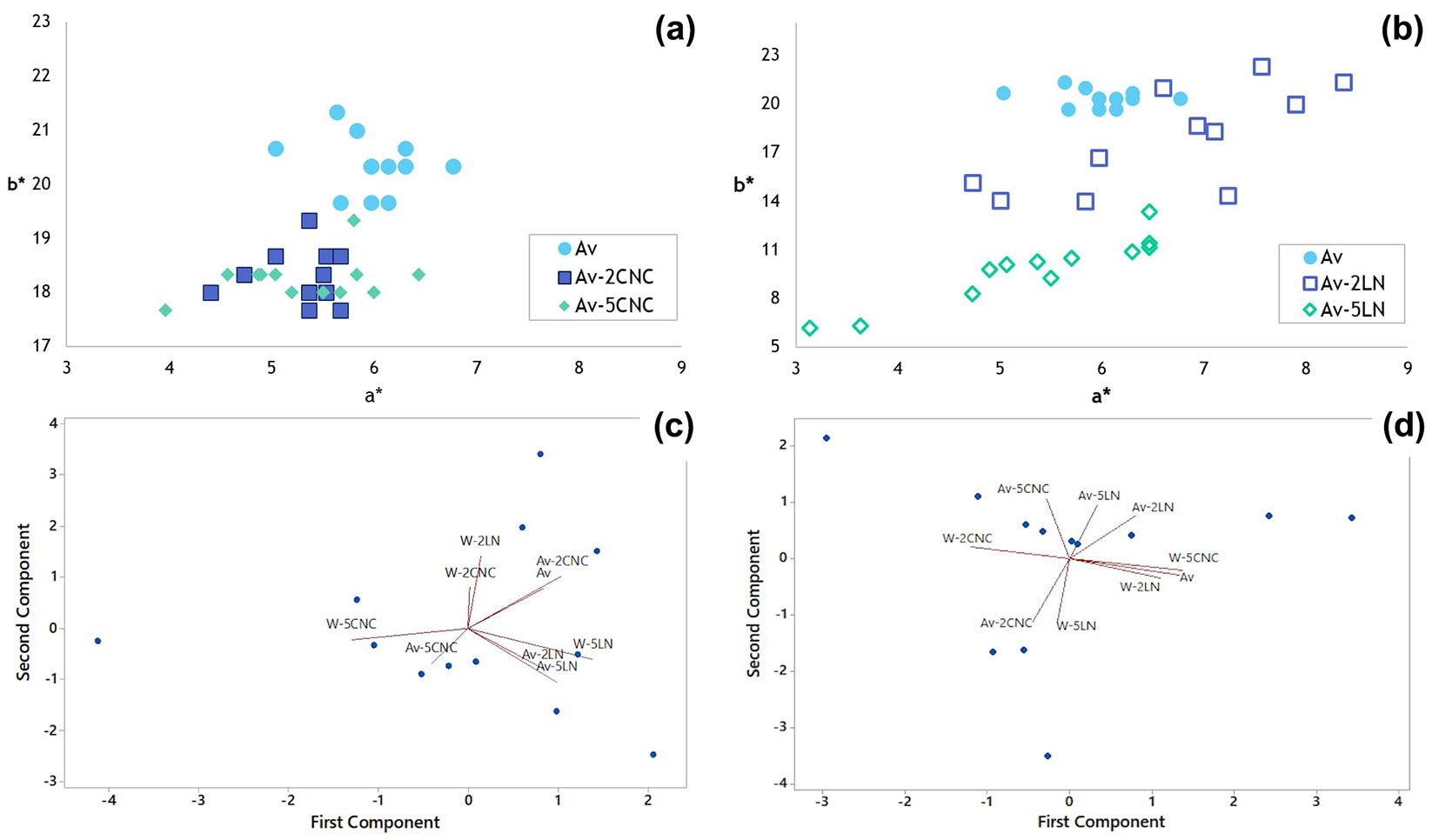

From Tab. 2 and Fig. 2, it is evident that beech wood coated with Av showed an increase in the two parameters a* and b*, displaying a colour drift towards red-orange, while brightness decreased towards slightly darker tones (L* shifted from 86 to 79). CNC did not significantly affect brightness, though a certain decrease in L* was observed at both concentrations (L* before treatment was 82.4 and after dip-coating was 78.4 for Av-2CNC and for Av-5CNC was 84.1 and then became 80.5). In contrast, when water was used as matrix, L* increased in both concentrations (L* shifted from 85.7 to 86.5 in W-2CNC and from 84.5 to 85.9 in W-5CNC). CNC addition in AV (treatments Av-2CNC and Av-5CNC) was characterized by higher values of a* and b* (red orange tones) compared to the similar formulation in W (W-2CNC and W-5CNC, respectively).

Fig. 2 - Graphs of colour change of beech wood samples after coating treatment. (a) Biplot of CIELAB coordinates a* and b* for Av to Av-2CNC and Av-5CNC; (b) biplot of coordinates a* and b* for Av to Av-2LN and Av-5LN; (c) PCA results for ΔE*; (d) PCA results for weight changes.

Lignin affected colour change after dip-coating much more compared to the CNC samples, as indicated by the highest ΔE* values, with an increase of ΔE* when lignin concentration rises from 2% to 5%. The most evident changes were decreasing brightness and a strong drift towards blue (increasing b*).

While colour changes were strong when using lignin and CNC as additives for acrylic varnish, the differences in colour before and after dip-coating are less evident when water is used as medium for the respective coating formulations.

It is important to remark that when adding lignin to the used acrylic coating, a colour change towards green was observed, which might be due to lignin structural modification during polymerization of the acrylic resin.

A PCA analysis was performed on 324 replicates for colour measurements (Fig. 2c). The PCA showed three different clusters, whose grouping depended mainly on the concentration but also on the type of additive (LN or CNC). In fact, formulations with lignin were mostly grouped together (AV-2LN, AV-5LN, W5LN). However, W-2LN clustered together with the other formulations with 2% concentration. The last group is formed by the highest percentage of CNC for both commercial acrylic coating and water formulations (AV-5CNC and W-5CNC). This means that colour change is influenced by both additive type and concentration.

Weight and thickness

In Tab. 3 the weight of the samples before and after dip-coating is reported, as well as the final coating thickness measured using an optical microscope.

Tab. 3 - Mean values (± standard deviation) of weight before and after dip-coating in coatings and coating thickness after fully drying.

| Treatment | Before dip-coating (g) |

After dip-coating (g) |

Weight gain (%) |

Thickness (μm) |

|---|---|---|---|---|

| Av | 0.244 ± 0.028 | 0.316 ± 0.026 | 23 | 7.11 ± 0.05 |

| Av-2CNC | 0.249 ± 0.027 | 0.279 ± 0.028 | 11 | 6.70 ± 0.03 |

| Av-2LN | 0.256 ± 0.014 | 0.285 ± 0.014 | 10 | 4.98 ± 0.05 |

| Av-5CNC | 0.254 ± 0.016 | 0.291 ± 0.019 | 13 | 5.14 ± 0.04 |

| Av-5LN | 0.263 ± 0.011 | 0.289 ± 0.013 | 9 | 6.96 ± 0.02 |

| W-2CNC | 0.238 ± 0.026 | 0.275 ± 0.028 | 14 | 3.84 ± 0.01 |

| W-2LN | 0.239 ± 0.025 | 0.252 ± 0.027 | 14 | - |

| W-5CNC | 0.238 ± 0.028 | 0.252 ± 0.028 | 6 | 2.72 ± 0.02 |

| W-5LN | 0.246 ± 0.021 | 0.251 ± 0.021 | 2 | - |

Samples dipped in Av showed an increase in weight of about 23%, whereas a lower weight gain was observed when CNC or lignin were added to the acrylic coating (Tab. 3). Further, no significant difference in weight gain between the two concentrations of CNC and LN used was recorded. Surprisingly, CNC addition decreased the thickness of the final coating with increasing CNC concentration. This might be due to a chemical reaction between CNC and the acrylic resin; after water evaporation, there might be a curing between CNC particles due to hydrogen bonds. Higher hydrophobicity of lignin, limiting the homogenization with acrylic varnish and water, could explain the higher final thickness compared to the CNC-modified coatings.

A PCA analysis was performed also on weight variation (Fig. 2d). In this case, only Av, W-5CNC and W-2LN formed a cluster. This means that Av affected the weight variation as well as W-2LN and W-5CNC. In fact, since lignin has a high molecular weight, CNC-modified coating can be comparable to lignin only if CNC concentration is 5%.

The thickness of the coating was negligible, especially when using water as medium.

Surface wettability test

Tab. 4 shows internal contact angle, wetting time and solid content of the different coating formulations tested.

Tab. 4 - Contact angle of coated wood after water drop was released and wetting time needed for complete absorption. Solid content is also reported.

| Treatment | Contact angle (deg) |

Wetting time | Solid content (%) |

|---|---|---|---|

| Control | 0 | 5′ 30″ | - |

| CNC | - | - | 92.6 |

| LN | - | - | 95.6 |

| Av | 44.3 | 45′ | 34 |

| Av-2CNC | 56.33 | 25′ | 35.17 |

| Av-2LN | 39.55 | 30′ | 35.23 |

| Av-5CNC | 54.16 | 45′ | 36.93 |

| Av-5LN | 49.9 | 45′ | 37.08 |

| W-2CNC | 28.5 | 2′ 30″ | 1.85 |

| W-2LN | 53.5 | 1′ 30″ | 1.91 |

| W-5CNC | 37.15 | 9′ | 4.63 |

| W-5LN | 52.45 | 3′ | 4.78 |

Wetting tests showed that Av-5LN increased the contact angle making the surface more hydrophobic. Such effect is even stronger when only water was used as medium instead of Av (W-2LN, W-5LN). However, their respective wetting times are strongly reduced compared to the acrylic coatings.

Surprisingly, CNC at 2% led to an increase of the contact angle showing a more water-repellent behaviour. By adding 5% of CNC, a similar increase in contact angle was observed, but additionally wetting time was comparable to the acrylic coating (Av). Likely, CNC forms intensive hydrogen bonds with the waterborne acrylic coating, making the OH groups in wood less accessible for water. Indeed, increase of contact angle corresponds also to a small increase in solid content.

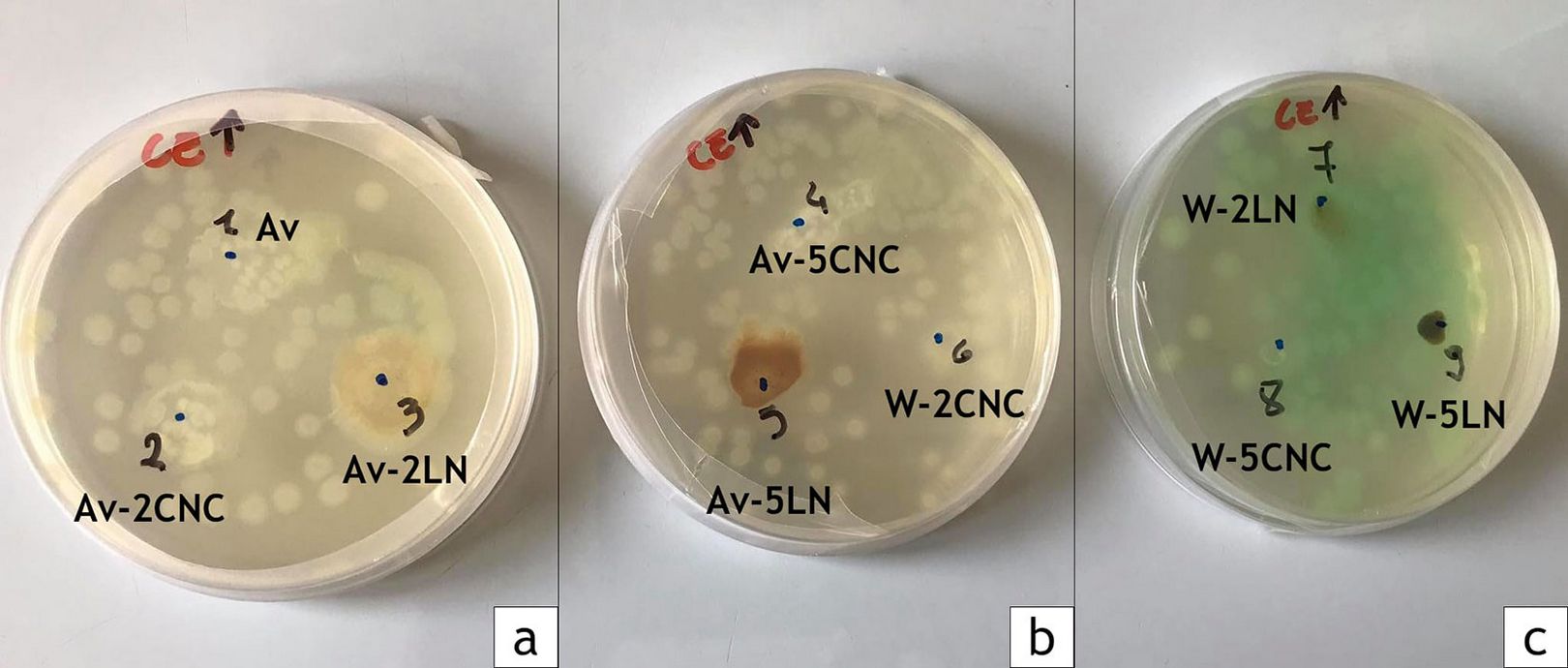

Antibacterial activity test

As mentioned above, two parallel tests were conducted in order to monitor the antibacterial activities of the samples, one using only the coating formulations and the other using the coated wood samples. In Fig. 3 the first part of the test is shown, where the varnish solutions were placed on agar plates, previously inoculated with bacterial suspension, and the image was taken after 20 h of incubation at 37 °C. In the samples W-2LN, W-5LN and W-5CNC a blue-green colouring appeared after 12 h, which can be attributed to the production of phenazines (i.e., pyocyanin and other “accessory respiratory pigments” - [9]).

Fig. 3 - Bacterial activity of the various coating formulations after 20h of incubation at 37 °C. (a) Samples Av, Av-2CNC and Av2-LN; (b) samples Av-5CNC, Av-5LN and W-2CNC; (c) samples W-2LN, W-5CNC and W-5LN.

As shown in Fig. 3, bacterial growth was observed soon after the coating samples were placed on agar plates. Bacterial colonies were well developed in every formulation, but a significant difference was noticed between the samples in the first two plates (Fig. 3a, Fig. 3b) and the samples in the last plate (Fig. 3c). A more intense bacteria activity is indicated by the green-blue colour of the agar plate in Fig. 3c, corresponding to the water-based formulations mixed with lignin and cellulose nanocrystals. However, also in the first two plates, containing the formulations Av, Av-2CNC, Av-2LN, Av-5CNC, Av-5LN and W-2CNC, bacterial colonies were numerous and large. Thus, it could be concluded that none of the coatings proved an antibacterial effect. The blue-green colour in Fig. 3c derives from the bacterial redox state, because P. aeruginosa produces pigments as secondary metabolites (i.e., pyocyanin, fluorescein, pyorubrin and pyomelanin) when reaching a stationary growth phase, often related to quorum sensing (QS) responses and modulation of pyocyanin as virulence factor ([31]). This response was more visible around the sample spots where the formulation contains lignin (sample 3 in Fig. 3a).

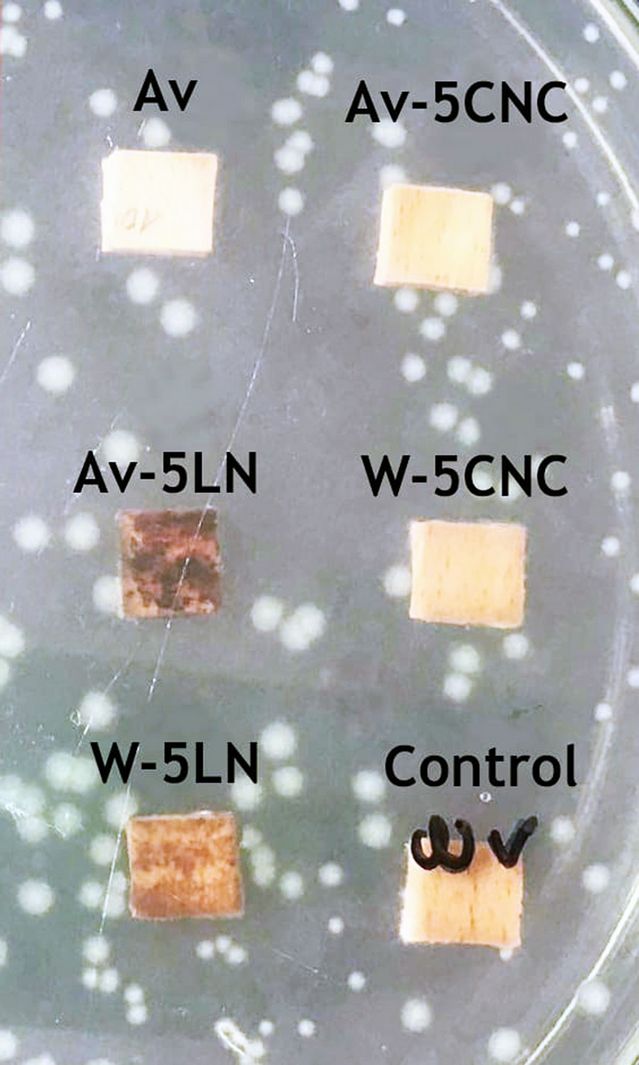

In the second part of the experiment, the coated wood specimens of the selected formulations were analyzed in comparison with virgin wood as control sample. The results showed that all of the treated samples were subjected to bacterial attack, although it seems that in the sample coated with pure Av an alteration in colony morphology occurred. The colony sizes near the control and distanced from Av were smaller (about 1 mm in diameter) in comparison to the size observed around the Av sample spots (diameter > 3 mm). Additionally, in the lignin-coated samples, even larger colonies with diameter > 4 mm were observed (Fig. 4).

FTIR spectroscopy and FTIR mapping analysis

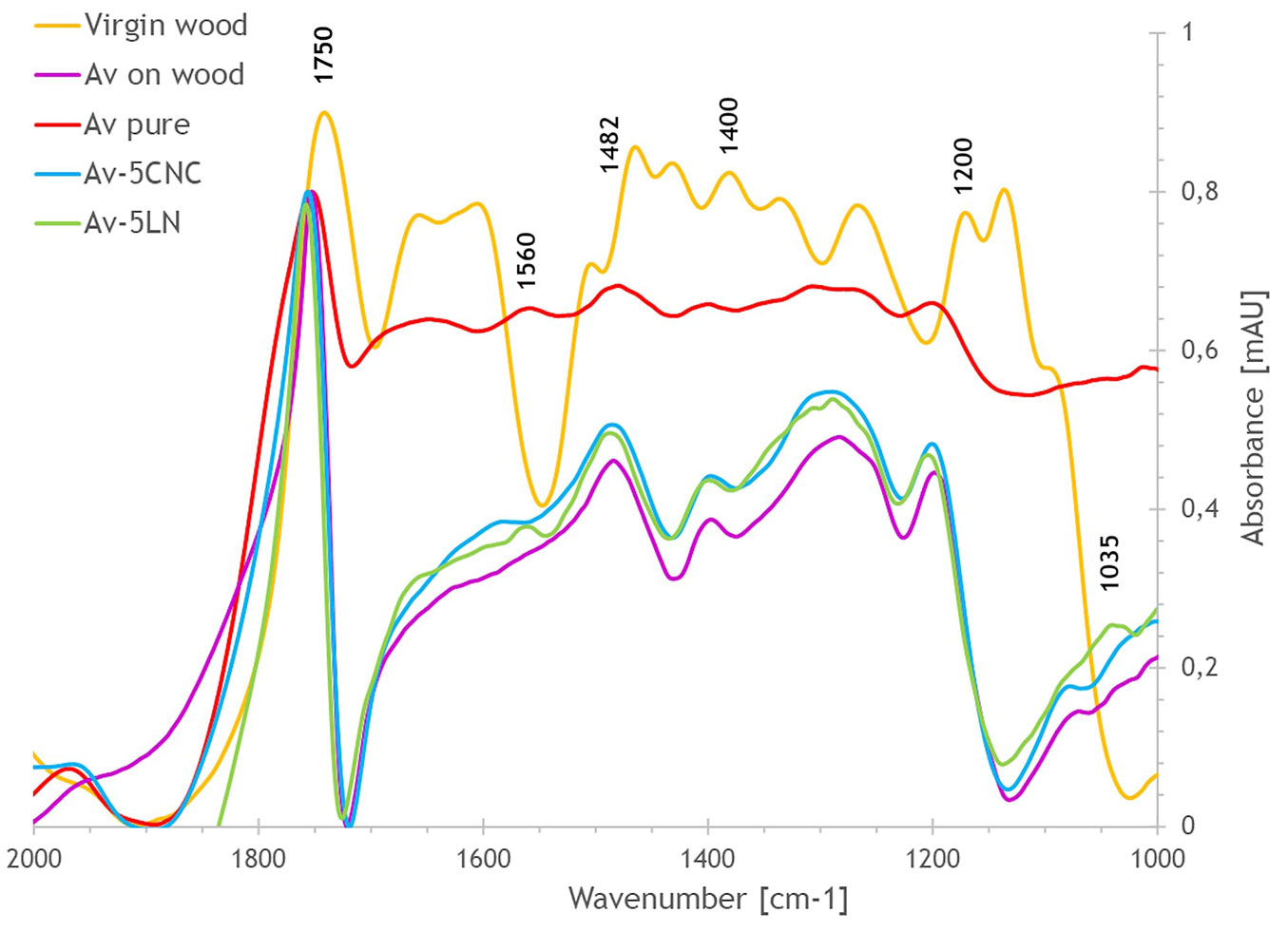

In Fig. 5 the FTIR spectra of untreated wood (Virgin wood), pure acrylic resin (Av pure) as well as coated samples (Av on wood, Av-5CNC and Av-5LN) are shown. IR band assignments for beech wood were listed according to Bodîrlau et al. ([3]) while acrylic IR band assignments were found in Rao et al. ([26]) and Akbarnezhad et al. ([2]). After wood coating, the IR bands which are exclusively attributed to wood, disperse under the Av signal, the spectrum becomes flat and the most prominent peaks (1750, 1482, 1400, 1200 cm-1) are related to acrylic varnish. Conversely, the peak at 1284 cm-1 in the spectrum of Av on wood seems to be the sum of several peaks related to both wood and acrylic coating. In Fig. 5 the spectra of the coatings Av-5CNC and Av-5LN did not show relevant differences since the predominant signal is still from the acrylic matrix of the coating. In particular, in Av-5LN peaks at 1560 and 1035 cm-1, also present in Av pure, are still evident. The peak at 1560 cm-1 in Av-5LN can be assigned to C-N ([42]) and the one at 1035 cm-1 can be attributed to the aromatic C-H in-plane deformations as well as C=O stretching of lignin ([44]). However, significantly more signal noise was registered for the lignin containing coating Av-5LN, which suggests heterogeneity of the prepared coating layer.

Fig. 5 - Comparison of FT-IR spectra of pure acrylic resin (Av), control sample (Virgin wood), and Av-coated wood (Av on wood); FT-IR spectra of CNC and LN mixed with Av (Av-5CNC, Av-5LN) and pure acrylic resin (Av pure) are displayed.

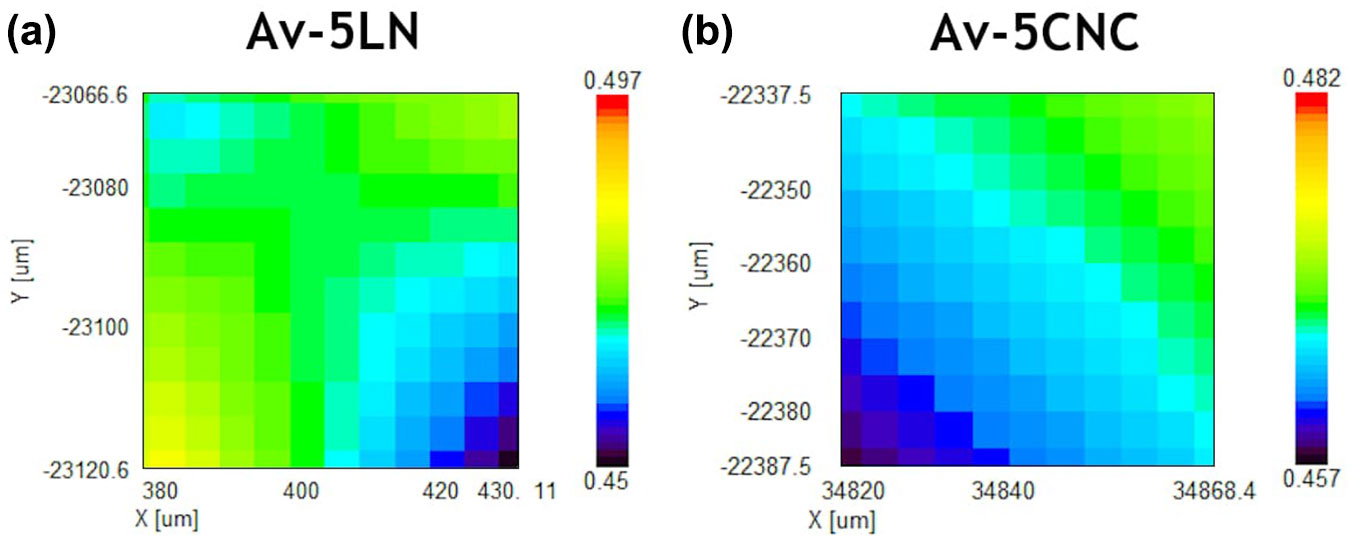

FTIR mapping was applied in order to investigate the homogeneity and distribution of the coatings and their CNC and lignin additives on the surface of the wood samples. In Fig. 6 the IR band at 1750 cm-1, assigned to carbonyl groups in methacrylate and holocellulose in beech wood ([3]), was used as the base for the image. In Fig. 6b, related to the sample containing cellulose nanofibrils, there are clearly areas with lower absorbance, attributed to CNC presence where the carbonyl band is less abundant relative to Av.

Fig. 6 - FT-IR mapping of acrylic coating mixed with (a) 5% lignin (Av-5LN) and (b) CNC (Av-5CNC), for the peak at 1750 cm-1.

Discussion

Acrylic varnishes have interesting properties, as they are available in water-borne formulations and are therefore considered less toxic than solvent-borne products. In general, acrylic coatings show a quite interesting colour stability, but they are sensitive to mold fungi on the wood surface during weathering ([2]) and for this reason increasing their resistance to biotic attack is a goal to be pursued. Water repellent coatings can contribute to its resistance, but in this case a sufficient water vapour permeability is necessary to allow moisture escaping from the wood surface after a wetting event ([12]).

The addition of nanocellulosic materials represents a viable approach to enhance the functionality and the end user value of coatings. Because of their morphology, nanocellulosic materials provide a large surface-to-volume ratio, which allows to interact intensively with the surrounding wood components, therefore enhancing the mechanical properties of wood ([18]).

While inorganic nanoparticles have already been implemented in various coating solutions, the addition of bio-based nanofillers is still at an early development stage and mostly studied at the laboratory level.

In this study, CNC showed a satisfying performance regarding water sorption, as indicated by the higher contact angle recorded. The best results were obtained with the highest percentage of CNC, which is consistent with Kluge et al. ([18]), who showed that water repellence of acrylic based formulations was not negatively affected by nanocellulose addition. Av resin polymerization in presence of CNC might have shielded the OH functional groups of CNC from water, while CNC could have served as a structural scaffold during polymerization, leading to a higher water repellence than observed for pure Av resin.

Further encouraging results from CNC addition to Av were that weight gain and solid content after dip-coating did not significantly increase compared to the original Av varnish, but CNC at 2% conferred a certain degree of hygroscopicity. Increasing CNC percentage, it was observed an increased wetting time, even if the solid content was at almost the same measured at 2% in CNC concentration. This result introduces a different perspective on the role of solid content, which in coating technology has proved to directly correlate with hydrophobicity ([18]), but in the specific application of CNC the network of nanocrystal add new properties less affected by the parameter of solid content.

The addition of CNC to wood coatings showed a weak impact on optical properties. In fact, ΔE* was low and a* was quite similar to the previous status, but b* decreases slightly. This might depend on the small size of the CNC particles, as previously reported by Kluge et al. ([18]). In other words, the nanocrystal dimensions allow the light to pass through the coating film without redirecting the beam. Therefore, if the aesthetical features of the product shall be preserved, coating with CNC additives is a valid approach.

Concerning bacterial interaction with CNC, cellulose nanofiber (with diameter range 2.3-4.5 nm and length 44-108 nm) were not able to hinder bacterial growth. This finding is in agreement with De Cesare et al. ([7]), who reported an adaptive growth interaction of bacterial cells with eco-compatible nanofibers with a higher diameter range of 10-100 nm. Nevertheless, it is well described that Burkholderia and Pseudomonas strains, but also E. coli isolates, are able to attack nanomaterials and produce biofilms on them via sessile growth ([27], [30], [7]).

Using CNC as an additive, a light (or at least a coating not heavier compared to pure Av) and thin coating but with interesting properties like transparency and uncompromised hydrophobicity can be obtained. However, since we registered no clear improvement of properties compared to the pure Av coating, no evident advantage for industry was found so far. To this aim, further analyses are needed aimed to investigate the effects of decreasing the solid content of the acrylic varnish on wood mechanical properties, which has proven quite promising ([18], [24], [41]).

In this study, the viscosity of coatings was not analysed, though this parameter should be taken in consideration for industrial applications, as it could compromise coating sprayability and additives dispersion. We analyzed CNC dispersion by FT-IR mapping and some areas with low absorbance were visible, likely due to CNC aggregation (Fig. 6). Similarly, Marini et al. ([19]) noticed that chemical modification of CNC needs to be considered to ensure the homogenous dispersion of CNC, even if it might affect costs and feasibility of the coating production at an industrial level.

Lignin has huge potential for future coating formulations because of its hydrophobic nature. In this study, lignin mixed with water gave better results than mixed with Av regarding the contact angle, but the wetting time using 2% of lignin (W-2LN) was too low compared to Av coating (Tab. 4). This could be explained by a not homogenous dispersion of lignin in the coating (see Fig. 1). Thus, the chemical modification of lignin seems more important than for cellulose in order to increase its miscibility. Several investigations focused on the addition of lignin to polyurethane-based coatings ([14], [17]), but studies on lignin in acrylic coatings are rare.

Concerning colour change, a content-depending shift to bluer and darker colour was recorded in all lignin-containing formulations. Therefore, lignin application on coated wood affects its original colour, but this permits additional wood protection against UV light as lignin acts as UV absorber ([35]). Hence, according to Ozgenç et al. ([21]), lignin can provide colour stabilization when a waterborne acrylic coating is applied in outdoor condition, because transparent coatings require more frequent maintenance than pigmented coatings, as UV light penetrates and degrades the film layer and decomposes the wood underneath ([20]).

Our results show that lignin did not add antibacterial activity to wood coating as expected. This finding seems to be in contrast with Teaca et al. ([35]), who reported that phenols leached from lignin can be absorbed by treated wood surfaces and act efficiently as biocides, when testing against rot fungi. However, P. aeruginosa strain AP02-1 is an environmental isolate with hydrocarbon-degrading abilities and able to tolerate and co-metabolize some aromatic compounds ([23], [25]). This could explain the limited efficacy of lignin in inhibiting PA02-1 growth. Surprisingly, the PA02-1 isolate can exploit lignin for accelerating the external production of QS factors (pyocyanin), often involved in the virulence and adaptive response to environment of P. aeruginosa ([31]). However, this effect might appear higher in W-LN formulations and less evident in the Av-LN ones, and this might suggest, at least for this strain, that Av is able to produce delaying effects in QS responses, specifically related in the production of phenazines. Interestingly, Av and lignin interact in the alteration of colony morphology. For P. aeruginosa, the different aspect of colonies may reflect difference in cell virulence. In this work morphological evolution of the CFU near the wood coated with Av and with Av-LN mixture show a larger colonies which can be associated with enhanced adaptive response to the stressing environment ([34]). However, in this case the Av coating is less related to size enlargement of the colonies in respect to Av-LN mixture, and this might indicate that wood interacts with some components of acrylic varnishes reducing eco-toxicity. On the other hand, the W-LN mixtures are not associated to relevant variation of morphotype, and thus we hypothesize that lignin was strongly adsorbed to the wood structure and not diffused around the material. The fast production of phenazines in P. aeruginosa induced by the W-LN formulations is intriguing, because pyocyanin has proved to be efficient against fungi and bacteria and it can be considered a relevant biotechnological metabolite with antimicrobial activity ([15]) which could be also used as a purified component of Av.

FTIR mapping has proved to be an efficient tool to test the homogeneity of wood coatings with bio-based additives. Indeed, we observed a low absorbance in some areas where CNC and lignin apparently aggregated during coating. This could represent a fairly relevant problem which still hampers the industrial application of such bio-based additives.

Conclusions

In this study, the use of CNC as an additive to wood coatings showed promising results. A high percentage (5%) of CNC in acrylic coatings decreased water sorption of beech wood, with no weight gain and a low colour change. The main disadvantage was the lack of any bacterial resistance. Flocculation of CNC particles is also a well-known weakness which must be overcome before their industrial application.

Mixing lignin with Av did not add any significant improvement to coatings. Lignin showed a better water sorption with water as a formulation matrix (both in W-2LN and in W-5LN). Also, a colour change of wood samples was observed using lignin mixed with Av as coating, which indicates an unknown chemical reaction. For both cellulose and lignin, particle agglomeration was evident using FTIR mapping. The results obtained from bacterial resistance tests open new perspectives because the addition of lignin apparently promotes the production of secondary metabolites in the medium (i.e., pyocyanin, fluorescein, pyorubrin and pyomelanin) which could act as biocontrol agents against other pathogens.

From the point of view of coating industry, it seems more viaable to produce acrylic coatings mixed with CNC, also because CNC production is almost at pre-industrial scale and the investigated properties are quite interesting. Yet, further research is needed and several unresolved tasks need to be completed before the industrial application of coatings with lignin and acrylic formulations, while mixing lignin with polyurethane seems more feasible. Furthermore, lignin has a high variability and the final properties depend on the extraction process, so its use at industrial scale still needs to be improved.

CNC and lignin are renewable and highly abundant resources, but the currently limited usage of these two compounds urgently calls for their more efficient application, in order to add value to industry side-streams and create new bio-based materials for bio-building applications.

Author Contribution

Experimental plan MR. Data acquisition JJ and ST, Results and Discussion all the authors. First draft MR, EDM, ST and JJ. Reviewing, checking and improving the manuscript GSM, FZ and VV. Final version checked by all the authors.

Acknowledgements

This study started in the frame of PRIN-MIUR 2015 (Research Projects of National Interest by the Italian Ministry of Education, University and Research) “Wood value-chain” project, grant no. 2015YW8 JWA, coordinated by G. Scarascia Mugnozza. Further support was received by the “Departments of Excellence - 2018” program (Dipartimenti di Eccellenza) of the Italian Ministry of Education, University and Research for the project “Landscape 4.0 - Food, wellbeing and environment” of the Department for Innovation in Biological, Agro-Food and Forest Systems (DIBAF) of the University of Tuscia. This study has continued in the frame of the pfoject PON-MISE (“Imprese e Competitività”) F/2000 03/01-03/X45 “Innovazione e sostenibilità della filiera Foresta-Legno: bioeconomia circolare del legno e valorizzazione di foreste dell’Italia centro-meridionale”.

References

CrossRef | Gscholar

Gscholar

Gscholar

CrossRef | Gscholar

CrossRef | Gscholar

Gscholar

Gscholar

Gscholar

CrossRef | Gscholar

Supplementary Material

Authors’ Info

Authors’ Affiliation

Swati Tamantini 0000-0002-1244-064X

Manuela Romagnoli 0000-0002-2568-6411

Vittorio Vinciguerra 0000-0003-1037-3567

Florian Zikeli 0000-0002-7842-2655

Giuseppe Scarascia Mugnozza 0000-0003-0357-4360

Department of Innovation in Biological, Agro-Food and Forest Systems - DIBAF, University of Tuscia, Viterbo (Italy)

Department of Agricultural and Forest Sciences - DAFNE, University of Tuscia, Viterbo (Italy)

Institute of Chemical, Environmental and Bioscience Engineering, Technische Universität, Wien (Austria)

FINEDIN s.r.l., Taviano, LE (Italy)

Corresponding author

Paper Info

Citation

Jusic J, Tamantini S, Romagnoli M, Vinciguerra V, Di Mattia E, Zikeli F, Cavalera M, Scarascia Mugnozza G (2021). Improving sustainability in wood coating: testing lignin and cellulose nanocrystals as additives to commercial acrylic wood coatings for bio-building. iForest 14: 499-507. - doi: 10.3832/ifor3782-014

Academic Editor

Mauro Maesano

Paper history

Received: Feb 13, 2021

Accepted: Sep 02, 2021

First online: Nov 11, 2021

Publication Date: Dec 31, 2021

Publication Time: 2.33 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2021

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 34604

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 28338

Abstract Page Views: 3150

PDF Downloads: 2575

Citation/Reference Downloads: 10

XML Downloads: 531

Web Metrics

Days since publication: 1546

Overall contacts: 34604

Avg. contacts per week: 156.68

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

Total number of cites (since 2021): 14

Average cites per year: 2.80

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Research Articles

Validation of models using near-infrared spectroscopy to estimate basic density and chemical composition of Eucalyptus wood

vol. 17, pp. 338-345 (online: 03 November 2024)

Technical Advances

Technical properties of beech wood from aged coppices in central Italy

vol. 8, pp. 82-88 (online: 04 June 2014)

Research Articles

Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal

vol. 10, pp. 669-679 (online: 11 July 2017)

Research Articles

NIR-based models for estimating selected physical and chemical wood properties from fast-growing plantations

vol. 15, pp. 372-380 (online: 05 October 2022)

Research Articles

Characterization of technological properties of matá-matá wood (Eschweilera coriacea [DC.] S.A. Mori, E. odora Poepp. [Miers] and E. truncata A.C. Sm.) by Near Infrared Spectroscopy

vol. 14, pp. 400-407 (online: 01 September 2021)

Research Articles

Identification of wood from the Amazon by characteristics of Haralick and Neural Network: image segmentation and polishing of the surface

vol. 15, pp. 234-239 (online: 14 July 2022)

Research Articles

Study on the chemical composition of teak wood extracts in different organic solvents

vol. 14, pp. 329-336 (online: 09 July 2021)

Research Articles

Characterization of VOC emission profile of different wood species during moisture cycles

vol. 10, pp. 576-584 (online: 08 May 2017)

Research Articles

Examining the evolution and convergence of wood modification and environmental impact assessment in research

vol. 10, pp. 879-885 (online: 06 November 2017)

Research Articles

Mechanical and physical properties of Cunninghamia lanceolata wood decayed by brown rot

vol. 12, pp. 317-322 (online: 06 June 2019)

iForest Database Search

Google Scholar Search

Citing Articles

Search By Author

Search By Keywords