Technical properties of beech wood from aged coppices in central Italy

iForest - Biogeosciences and Forestry, Volume 8, Issue 1, Pages 82-88 (2015)

doi: https://doi.org/10.3832/ifor1136-007

Published: Jun 04, 2014 - Copyright © 2015 SISEF

Technical Advances

Abstract

The aim of this study is to assess the features of timber from aged coppices in transition to high forests to provide a basis for their more efficient utilisation. The introduction of a territorial protection policy and improvements in the socio-economic conditions of people living in mountain areas have led to a transition towards less intensive use of forests, which has resulted in the conversion of beech coppices into transitional high forests. The suspension of cutting has produced so-called “aged coppices”, now at the stage of thinning. In this condition, high-quality timber is difficult to obtain and the wood supply is highly variable, making efficient processing during manufacture difficult. To investigate features of the timber, clear specimens from two sites, Prati di San Bartolomeo and Fontenova, were analysed. Physical and mechanical characteristics were as follows: dry density, 719 and 688 kg m-3; basic density, 585 and 560 kg m-3; radial shrinkage, 7.06 and 7.17%; tangential shrinkage, 12.43 and 11.72%; volumetric shrinkage, 19.05 and 18.51%; axial compression strength, 54.7 and 54.4 MPa; static bending strengths, 100.9 and 108.4 MPa; and Brinell hardness, 29.8 and 27.7 N mm-2. Wood colour was also measured, as it is an important parameter for the end users. It was assessed with the CIELAB system. The wood colour coordinates before ageing exhibited the following values: L*=82.06, a*=4.92, and b*=17.36. After 504 hours of light exposure, wood became darker (L* =68.99) and more yellow (a*=9.49; b*= 29.57). The results of this study highlight that beech wood from aged coppice in Central Italy shows interesting qualitative features, suggesting that it can be put to more profitable use than as firewood.

Keywords

Coppice in Transition, Density, Shrinkage, Mechanical Properties, Brinell Hardness, Wood Colour, Fagus sylvatica L., Central Italy

Introduction

Coppice management has been deeply affected by economic and social changes in Europe since the 1950s. During the last century, the replacement of firewood with fossil fuels and the massive migration of people from mountain villages to towns has led to a change from traditional management of coppice to irregular coppicing or abandonment of management. Coppices have been progressively neglected in Italy ([12], [47]), and the suspension of their exploitation has produced “aged coppices”, leading to alternative forms of traditional coppice management, such as the conversion to high forest systems ([3]). Conversion consists of thinning out the shoots from the aged coppices to produce a transitory high forest stand.

In the last 50 years, different approaches to coppice conversion have produced variable results in Europe, depending also on the stand conditions ([72], [70], [34], [43], [55], [2], [50], [56]). The transition towards a less intensive use of forests, which was considered more productive and more ecologically functional ([7]), was also due to the introduction of policies aimed at a territorial protection ([6], [18], [10], [25]). As a consequence, such forests were actively or passively converted into high forest stands, as their management switched to other goals, like timber production, biodiversity conservation, etc. Thus the transition to less intensive managing regimes with different environmental features is important, particularly for mountainous areas of the Mediterranean countries ([11], [74], [20], [13], [33], [32]).

Coppices under natural evolution show a great structural variability, though a trend to conform to the typical structures of high forests is fairly clear. High forests have a prominent role in safeguarding biodiversity and promoting the non-productive functions of forests ([47], [14]). New silvicultural approaches are being applied to aged coppices with the aim of favoring their natural development, improving their stability and functionality, and enhancing their natural regeneration by seeds. As a result, coppice conversion is expected to increase further ([12]).

In Italy, coppices that are no longer exploited in the traditional way cover a large area. At present, aged coppices represent 89% of the whole Italian coppice surface area, and transitory high forests occupy about 150 000 ha ([29]). On the Apennines (central Italy) beech usually grows at altitudes above 900-1000 m, though relict sites are located at lower altitudes, providing evidence for a larger diffusion in the past ([41], [4], [5], [26]). According to the Italian National Forest Inventory ([29]), beech forests cover approximately 1 035 107 ha, and coppices in conversion are more than 78 000 ha, mainly located in the Apennines (61%). Many state beech stands are currently in the transition phase from coppice to high forest.

A common question is: might the aging coppices be a cost-effective source of wood other than firewood? At present, the main product from coppices under conversion to high forests is firewood ([38], [48]). In fact, coppices in transition produce a large amount of low-quality wood, i.e., branched and buckled stems, and discoloration of beech wood due to wounds, root die-back and dead branches is common ([59], [31], [71]). The red heartwood restricts the application of beech from coppices in transition to low-value products, with a consequent loss of financial value ([49], [71]). It seems to be difficult to obtain high-quality timber from coppices in transition, and wood supply is highly variable, making efficient processing during manufacture difficult. However, local public owners (e.g., Municipalities) would greatly benefit from a more profitable use of coppice wood.

In this paper, several physical and mechanical properties of beech wood from coppice converted into transitional high forest of central Italy were analyzed. Density, moisture shrinkage, dimensional shrinkage, and color variation were considered, and data obtained compared to literature. The potential uses of such wood for purposes other than energy production is also discussed.

Materials and methods

Two sites characterized by beech coppices converted into a transitional high forest were sampled on the Terminillo mountain (Leonessa Municipality, Rieti province, central Italy - Fig. 1): Fontenova (about 1460 m a.s.l.) and Prati di San Bartolomeo (about 1471 m a.s.l. - Tab. 1). Four trees from each site were randomly selected and felled; their main characteristics are displayed in Tab. 2. Log sections were collected from the whole tree at heights between 2 and 4 m. Test specimens were prepared from the logs according to the general requirements for physical and mechanical tests ([62]). The logs and the specimens were conditioned at 65% relative humidity and 20°C, to equilibrate at 12% moisture content.

Tab. 1 - Main features of the two aged beech coppices in central Italy from which samples were taken. Values in parentheses are standard deviations. (DBH): diameter at breast height.

| Characteristics | Fontenova | Prati di San Bartolomeo |

|---|---|---|

| Mean elevation (m a.s.l.) | 1460 | 1471 |

| Exposure | N | S-SE |

| Mean slope (%) | 30 | 40 |

| Soil | Middle clay soil. Deep soil with calcareous skeleton |

Middle clay soil. Deep soil with calcareous skeleton |

| Phyto-climate (Pavari) | Fagetum | Fagetum |

| Coordinates | 12°56’19” E / 42°32’51” N | 12°56’43” E / 42°30’41” N |

| Mean tree age (years) | 120 | 100 |

| Mean DBH (cm) | 49 (0.9) | 44 (0.6) |

| Mean height (m) | 21 (4.1) | 22 (7.3) |

| Trees (n ha-1) | 520 | 550 |

Tab. 2 - Main characteristics of the beech trees selected for sampling, and results of a comparison between the trees from each site (Mann-Whitney U-tests). (DBH): diameter at breast height.

| Sampled stand | Tree | Tree age (year) |

DBH (cm) | Height (m) |

|---|---|---|---|---|

| Fontenova | 1 | 150 | 54 | 24 |

| 2 | 135 | 50 | 22 | |

| 3 | 110 | 47 | 22 | |

| 4 | 97 | 45 | 20 | |

| Prati di San Bartolomeo | 1 | 130 | 58 | 23 |

| 2 | 100 | 43 | 22 | |

| 3 | 85 | 40 | 18 | |

| 4 | 107 | 46 | 22 | |

| p-value | - | 0.248 | 0.386 | 0.758 |

In accordance with UNI ISO 3131 standard ([65]), basic and dry density were calculated on a set of 223 specimens (20×20×30 mm). Tangential, radial and volumetric shrinkage were calculated considering the total dimensional variation from the fully swollen to the oven dry condition on the 223 specimens. Samples were cut, dried, and measured according to UNI ISO 4469 and UNI ISO 4858 standards ([68], [69]). In addition, the coefficient of shrinkage was calculated for each variable measured as the shrinkage value when moisture content decreases by 1% below the fiber saturation point, under the assumption of a linear relationship ([38]).

The compression strength (σy) was determined for a set of 231 specimens (20×20×30 mm) at 12% moisture content, according to UNI ISO 3787 ([67]), and the bending strength (σb) was obtained for a set of 80 specimens (20×20×30 mm) at 12% moisture content, according to UNI ISO 3133 ([66]).

The resistance to indentation (formerly Brinell hardness) was quantified by the Brinell method for a set of 80 specimens (50×50×40 mm) at 12% moisture content, according to UNI EN 1534 ([63]).

Thirty samples were chosen for color analyses, and three measurements for each sample were performed after exposure to 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 24, 48, 72, 96, 120, 144, 168, 216, 312, 408 and 504 hours of irradiation carried out in a Model 1500E Solar Box (Erichsen Instruments). The system is equipped with a 2.5 kW xenon-arc lamp and a UV filter that cuts off the spectrum at 280 nm. The samples were exposed in the Solar Box chamber at 550 W m-2, 55 °C, with the UV filter at 280 nm. The experimental conditions were chosen to simulate exposure to full sunlight.

Color was quantitatively characterized by an X-Rite CA 22 reflectance spectrophotometer. The characteristics of the color-measuring instrument are as follows: color scale CIEL*a*b*; illuminant D65; standard observer 10°; geometry of measurement 45°/0°; spectral range 400-700 nm; spectral resolution 10 nm; measurement diameter 4 mm; and white reference supplied with the instrument. The CIELAB color system was used, where L* describes the lightness, while a* and b* describe the chromatic coordinates on the green-red and blue-yellow axes, respectively. The differences in lightness (ΔL*), chromatic coordinates (Δa* and Δb*), and total color (ΔE*) were then calculated using these parameters according to UNI-EN-15886 ([64]). The total color difference (ΔE*) between two measurements (L*1 a*1 b*1 and L*2 a*2 b*2) is the geometric distance between their positions in CIELAB color space. It is calculated as (eqn. 1):

Statistical analysis was performed using the Statistica® 2007 (StatSoft Inc., Tulsa, OK, USA ) software package. ANOVA and MANOVA were applied when data were normally distributed; non-parametric Kruskal-Wallis and Mann-Whitney U-tests ([53]) were used when data were not normally distributed or showed a lack of homogeneity of variance after the Bartlett and Levene’s test ([75]). Differences among means were tested using the Tukey’s HSD post-hoc test (α = 0.05). Linear regression was applied on order to predict the variation of every chromatic coordinate (L* or a* or b*) as a function of the exposure time. Non-linear regression was used to predict the exposure time based on the three above chromatic coordinates.

Results and discussion

Physical properties

The physical properties of the beech wood from the two sites considered in this study are shown in Tab. 3. Significant differences between the two sites exist in dry density (p < 0.01), basic density (p <0.05), tangential shrinkage (p <0.05), and related coefficients (p <0.05). Statistically significant differences in the physical properties of wood from the two sites are mainly due to density, which seems the factor underlying the differences observed for the other parameters.

Tab. 3 - Physical properties of beech wood from aged coppices on the Terminillo mountain. Results of MANOVA and Tukey’s tests applied to each parameter. (SD): standard deviation; (ns): non significant (p>0.05).

| Property | Prati di San Bartolomeo | Fontenova | MANOVA results p-value |

||

|---|---|---|---|---|---|

| Sample no. |

Average value (SD) |

Sample no. | Average value (SD) |

||

| Dry wood density (kg m-3) | 124 | 719 (41.9) | 99 | 688 (40.6) | <0.01 |

| Basic density (kg m-3) | 124 | 585 (18) | 99 | 560 (28.2) | <0.05 |

| Radial shrinkage (%) | 124 | 7.06 (1.1) | 99 | 7.17 (1.0) | ns |

| Tangential shrinkage (%) | 124 | 12.43 (2.1) | 99 | 11.72 (1.6) | <0.05 |

| Volumetric shrinkage (%) | 124 | 19.054 (2.8) | 99 | 18.51 (2.5) | ns |

| Radial shrinkage coefficient | 124 | 0.24 (0.04) | 99 | 0.24 (0.04) | ns |

| Tangential shrinkage coefficient |

124 | 0.41 (0.07) | 99 | 0.39 (0.05) | <0.05 |

| Volumetric shrinkage coefficient |

124 | 0.64 (0.09) | 99 | 0.62 (0.08) | ns |

| Tangential and radial shrinkage ratio |

124 | 1.78 (0.26) | 99 | 1.66 (0.23) | <0.05 |

Growth conditions and site ecological factors, in particular elevation, soil and climate, may determine variations in wood properties. In addition, tree age and ring width, which are affected by the managing practices, may influence wood physical properties ([77]). Bouriaud et al. ([9]) found a weak though significant correlation between stand density and ring width or ring age in beech. Indeed, each tree reacts independently to environmental and anthropic factors, thus determining the mechanical properties of its wood. Moreover, forestry interventions aimed at regulating the diametrical growth are discontinuous, leading to individual differences in growth.

The mean values of beech wood parameters obtained in this study were compared with values from the literature (Tab. 4). Dry density values were similar to the average values reported for beech wood from high forest stands in Italy ([24], [17]), Greece ([52]), France ([15]), Hungary ([40]) and Croatia ([51]). Tsoumis ([61]) gives a dry density value of 700 kg m-3 for beech of unknown provenance. Basic density values were also similar to the average value (0.575 g cm-3) of wood from coppice stands of beech in the northern Apennines ([8]). On the other hand, values of shrinkage were higher than those reported from beech wood in other parts of Europe ([42], [40], [73], [51], [15], [52]), but similar to values reported for Greece by Tsoumis ([60]), and within the range reported by Giordano ([24]) for the Italian beech.

Tab. 4 - Physical and mechanical properties of beech wood derived from this study (last two columns) and from the literature. Measurement units were converted when necessary.

| Property | CIRAD ([15]) | Cividini ([17]) | Giordano ([24]) | Molnár et al. ([40]) | Nardi Berti ([42]) | Pöhler et al. ([49]) | Skarvelis & Mantanis ([52]) | Tsoumis ([60]) | Yilgor et al. ([73]) | Prati di San Bartolomeo |

Fontenova |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dry wood density (kg m-3) | - | 669 | 690 | 712 | - | 695 | 640 | 700 | - | 719 | 688 |

| Basic density (kg cm-3) | - | 547 | 610 | - | - | - | - | - | - | 585 | 560 |

| Radial shrinkage (%) | 5.7 | 5.55 | 2-5 | 6.4 | 5.8 | - | 5.5 | 5.8 | 5.3 | 7.1 | 7.2 |

| Tangential shrinkage (%) | - | 14.27 | 9-20 | 12.3 | 10.0 | - | 9.9 | 11.8 | 11.4 | 12.4 | 11.7 |

| Volumetric shrinkage (%) | - | 22.15 | - | 18.1 | 17.0 | - | 15.1 | - | - | 19.5 | 18.5 |

| Tangential and radial shrinkage ratio | - | - | 2.3-2.9 | - | - | - | - | - | - | 1.8 | 1.6 |

Compression strength (σy - MPa) |

- | 51.7 | 61.0 | 63.6 | 58.0 | - | 55.4 | - | 54.2 | 54.7 | 54.4 |

Static bending strength (σb - MPa) |

111.0 | 108.1 | 118.0 | - | 68-149 | 127.0 | 105.5 | 104.4 | 104.0 | 100.9 | 108.4 |

| Brinell hardness (Nmm-2) | - | - | - | 25.1 | - | 26.9 | - | - | - | 29.8 | 27.7 |

The shrinking behavior of the wood is a key factor in many uses. As an anisotropic material, wood presents differential dimensional changes in the three anatomical directions. The tangential/radial shrinkage ratio measures the tendency for wood to split and warp when moisture content varies. The tangential/radial shrinkage ratio in the study site is lower than that of beech from other locations in Italy, resulting in greater stability ([24]), although the Terminillo’s beech wood maintains the tendency to warp. This behavior is more similar to that of Carpinus betulus L. and Ostrya carpinifolia L. than to that of beech from coppiced forests in Italy ([8]). The tangential/radial shrinkage ratio of beech wood studied is also lower than that of wood from Turkey oak coppices in central Italy ([38]) and from Picconia azorica Tutin ([21]).

Sinković et al. ([51]) showed that less shrinkage occurs in wood of higher density, but we found no correlation between density (oven dry condition or basic density) and shrinkage. Lo Monaco et al. ([38]) found a correlation between density and shrinkage in wood from Turkey oak coppices in central Italy. In this study, rings observed in transverse sections of beech wood are highly variable in width, likely due to several factors including tree age, silvicultural practices, site conditions etc. Therefore, even in beech coppices in transition, tree density is not necessarily a good estimator of wood quality, as already stated by Zhang et al. ([76]).

Mechanical properties

The mechanical properties of beech wood from the sampled sites are shown in Tab. 5. No significant differences in mechanical properties between sites were detected after ANOVA, with the exception of the Brinell hardness. This difference can be explained by the difference in wood density, and is in accordance to the observation by Skarvelis & Mantanis ([52]) that hardness is more tightly correlated with density than with other mechanical properties.

Tab. 5 - Mechanical properties of beech wood from aged coppices on the Terminillo Mountain, and results of MANOVA and Tukey tests applied to each parameter. (SD): standard deviation; (ns): not significant.

| Property | Prati di San Bartolomeo | Fontenova | MANOVA results p-value |

||

|---|---|---|---|---|---|

| Sample no. |

Average value (SD) |

Sample no. |

Average value (SD) |

||

| Compression strength ( σy - MPa) |

124 | 54.7 (5.3) |

107 | 54.4 (8.3) |

ns |

Static bending strengths (σb - MPa) |

40 | 100.9 (19.9) |

40 | 108.4 (13.5) |

ns |

| Brinell hardness (Nmm-2) |

40 | 29.8 (2.5) |

40 | 27.7 (3.1) |

<0.05 |

The mean values of beech wood mechanical properties obtained in this study were compared with values from the literature as reported in Tab. 4. The average value for the axial compression strength of the Terminillo’s beech wood is similar to the value reported by Berti et al. ([8]), Skarvelis & Mantanis ([52]) for Fagus orientalis and Fagus sylvatica, and Yilgor et al. ([73]) for Fagus orientalis., though higher than those reported by Cividini ([17]), Stoyanoff & Entcheff ([54]), and Horvat ([28]).

Similarly, the average value for the static bending strength in this study is close to the value reported by CIRAD ([15]), Tsoumis ([61]), Yilgor et al. ([73]), and Skarvelis & Mantanis ([52]). However, it is lower than those obtained for wood from other sites in Italy ([24], [8]) and those for beech from central Europe ([49]).

Wood hardness is measured as the residual deformation representing the resistance to indentation, and is useful in determining whether a material is suitable for flooring. In this study, hardness values were lower than those reported for beech used in parquet flooring by Cividini ([16]), but higher than values obtained by Molnár et al. ([40]) and Pöhler et al. ([49]).

Color

Wood color is an important factor for the end-user, influencing the final price of the wood products. In this study, we quantified color changes in beech wood after light exposure. No significant differences were detected in color parameters between the two sites (Kruskall-Wallis test, p>0.05); therefore, the two data sets were pooled together for further analysis.

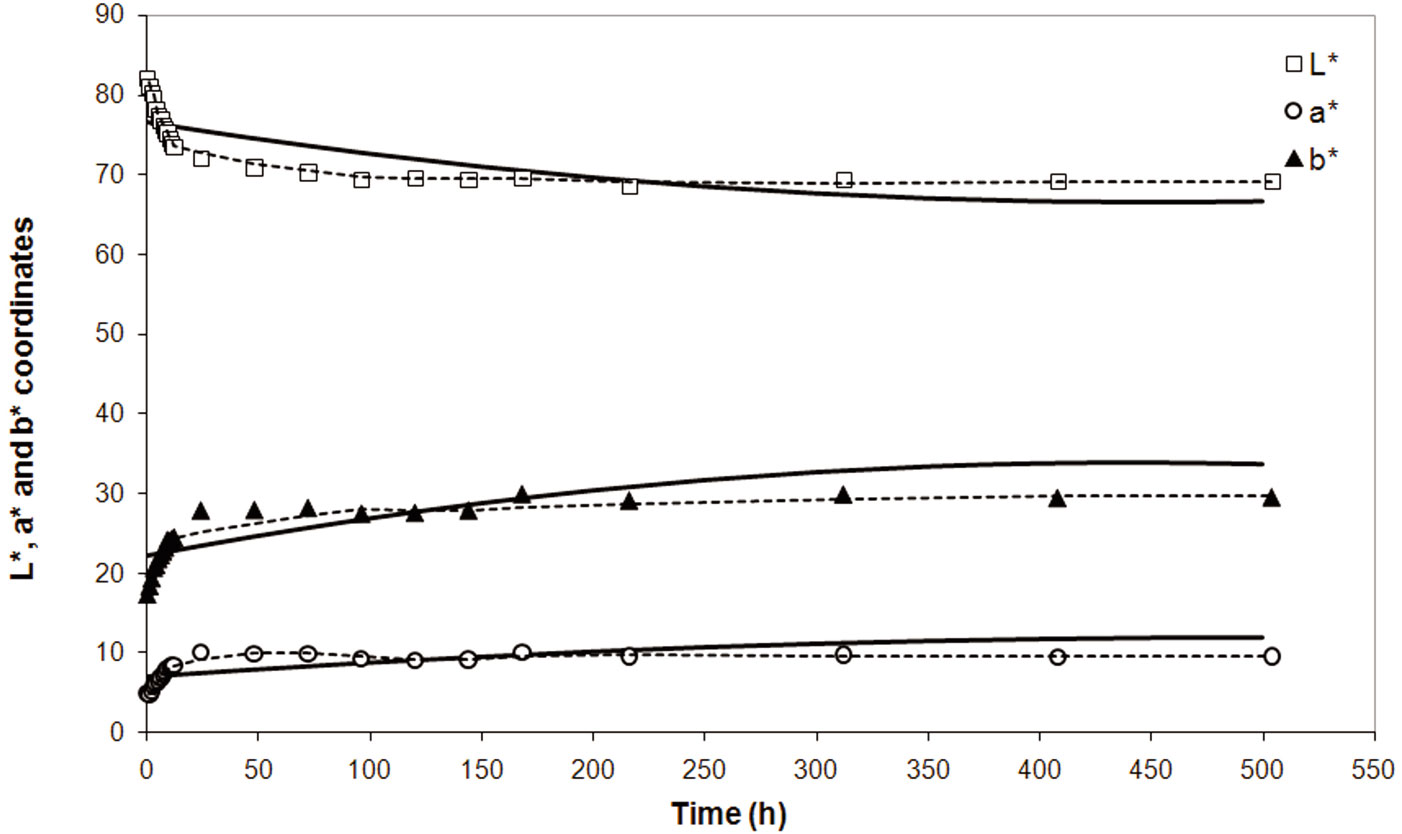

Wood color coordinates before the aging treatment were: L* = 82.06 ± 0.60; a* = 4.92 ± 0.15; b* = 17.36 ± 0.53 (Fig. 2). Such values are fairly similar to those reported for beech by Liu et al. ([35]) and Todorović et al. ([57]). Contrastingly, Miklečić et al. ([39]) found a slightly darker color (L* = 73.9 ± 1.0).

Fig. 2 - Changes in L*, a* and b* values in beech wood from aged coppices due to light exposure in a Solar Box for up to 504 hours. The dotted lines represent the interpolated values from the rolling average (L: n=2; a: n=2; b: n=4); the solid lines are from the regression analysis in Tab. 6.

Fig. 2 shows the variation in chromatic coordinates through time of treatment (light exposure). With increasing irradiation time, lightness (L*) clearly decreases, varying from 82.06 to 68.99 after 504 hours of exposure. The greatest change in lightness occurs within the first 48 hours of exposure, indicating a conspicuous darkening of the wood surface, and then L* reaches a steady state. Contrastingly, the parameters a* increased from 4.92 to 9.49 after 504 hours of irradiation, producing a slight change to red color in the treated material. Analogously, b* values increased from 17.36 (0 h) to 29.57 (504 h) during light exposure. Similar trends in color changes were also described for Fagus crenata ([58]).

Tab. 6 displays the results of the linear regression analysis carried out using the dependent variables L*, a*, b* as a function of the exposure time (t). All the models and coefficients were highly significant, indicating that the three color coordinates may be predicted quite accurately (R2adj = 0.49-0.68) based on the time to light exposure. Similarly, all the coefficient estimated by the regression analysis carried out for the dependent variable t as a function of the three color coordinates were highly significant (Tab. 7), suggesting that colorimetric parameters could be used to derive the exposure times of wood samples with a totally non-invasive approach.

Tab. 6 - Results of the three regression analyses for the dependent variables L*, a*, b* as a function of the light exposure time (t, expressed in hours).

| Variable | Parameter | Coefficient | p-value | R2-adj | Prob | Equation |

|---|---|---|---|---|---|---|

L*

|

Intercept | 76.615 | <0.01 | 0.541 | <0.01 | L* = 76.615 - 0.045 t + 0.00005 t2 |

t

|

-0.045 | <0.01 | ||||

t 2 |

0.00005 | <0.01 | ||||

a*

|

Intercept | 6.963 | <0.01 | 0.489 | <0.01 | a* = 6.963 + 0.020 t - 0.00002 t2 |

t

|

0.020 | <0.01 | ||||

t 2 |

-0.00002 | <0.01 | ||||

b*

|

Intercept | 22.19 | <0.01 | 0.684 | <0.01 | b* = 22.19 + 0.053 t - 0.00006 t2 |

t

|

0.053 | <0.01 | ||||

t 2 |

-0.00006 | <0.01 |

Tab. 7 - Regression analysis for the dependent variable t (time) as a function of the L*, a*, b* color coordinates.

| Parameter | Variable coefficient |

p-value |

|---|---|---|

| Intercept | 10525.09 | <0.01 |

L*

|

-256.27 | <0.01 |

a*

|

121.18 | <0.01 |

b*

|

-111.61 | <0.01 |

L* 2 |

1.67 | <0.01 |

a* 2 |

-11.27 | <0.01 |

b* 2 |

3.03 | <0.01 |

| R² adj | 0.891 | <0.01 |

| Equation | T = 10525.09 - 256.27L* + 121.18a* - 111.61b* + 1.67L*2 - 11.27a*2 + 3.03b*2 |

|

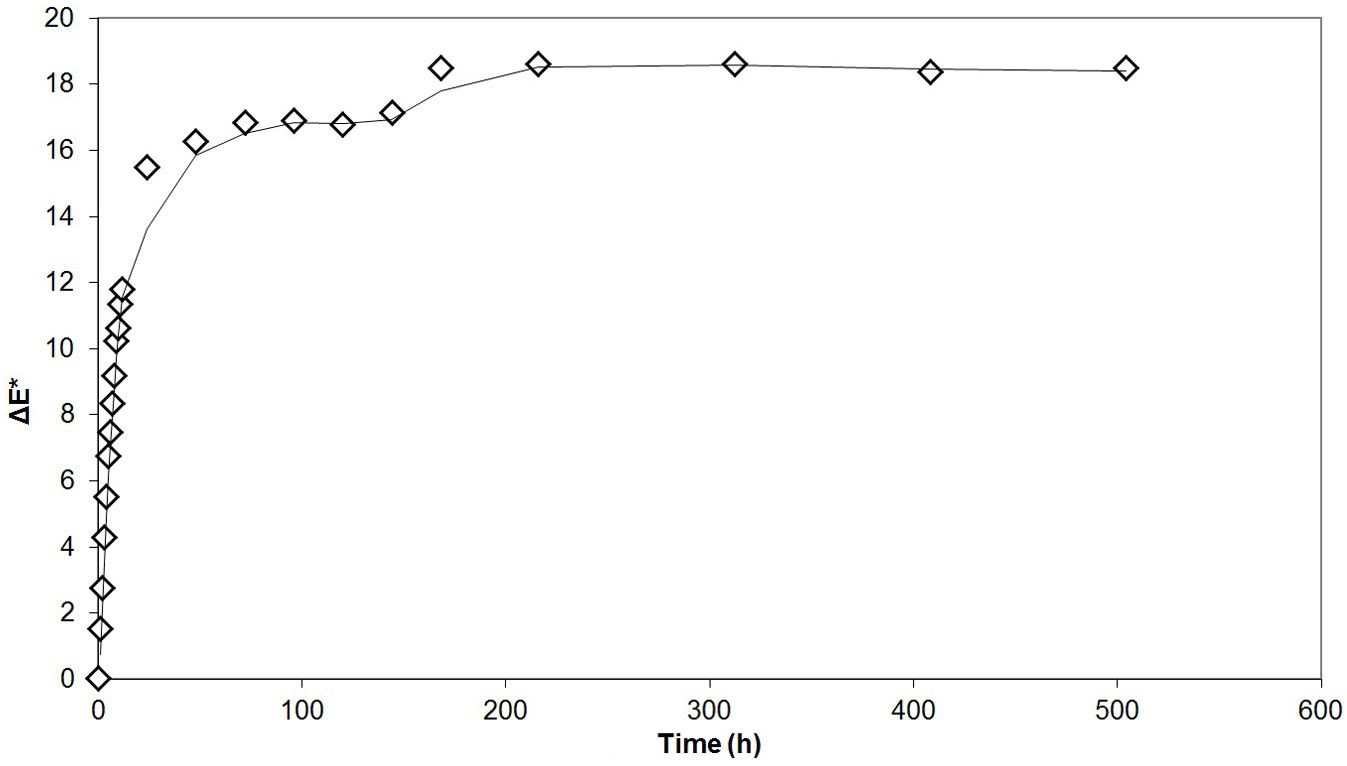

Color changes were also ascertained using ΔE* variations as functions of the time exposure to light (Fig. 3). After just 48 hours of exposure, ΔE* reached the value 16.23 and then continued to increase by small increments to reach the value of 18.46 at the end of irradiation. The rapid decrease of lightness and the increase in the chromatic coordinates can be ascribed to photo-degradation processes, which were also observed for other broadleaved tree species ([1], [22], [36], [37], [46]). The darker color indicates photo-degradation related to the decomposition of lignin due to the chromophore groups absorbing energy, especially in the UV part of the sunlight spectrum ([44], [45], [23], [27]).

Fig. 3 - Changes in ΔE* values in beech wood from aged coppices due to light exposure in a Solar Box for up to 504 hours.

Conclusion

The aim of this study was to assess the features of beech wood from aged coppices in central Italy to provide a basis for their more efficient and profitable exploitation.

Several physical and mechanical properties of beech wood from aged coppice from the study area were compared with information gathered from the literature. Beech wood from coppice in transition shows interesting qualitative characteristics, suggesting a more profitable use than firewood. Its mechanical properties make this material theoretically very attractive for industrial applications, such as in artifacts or floors. Moreover, the color analysis carried out on beech wood demonstrated that its characteristics are in the range reported for the species.

Nonetheless, defects exist that are a deterrent for the remunerative use of beech wood from aged coppices. For example, the red heartwood is an alteration making the wood from aged coppices unsuitable as industrial timber. Some physical parameters (e.g., shrinking) are also causes of concern, especially if the wood is not appropriately treated during drying.

In the short term, silvicultural practices could increase the production of wood with good technological qualities in aged coppices, though some timber defects are likely related to previous silvicultural management. More suitable silvicultural techniques, applications and choices are needed when planning interventions, since forestry actions aimed at regulating tree growth can deeply affect wood properties.

References

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

CrossRef | Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

CrossRef | Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

CrossRef | Gscholar

Gscholar

Gscholar

Gscholar

Authors’ Info

Authors’ Affiliation

Luca Calienno

Federica Balletti

Rodolfo Picchio

Department of science and technology for Agriculture, Forests, Nature and Energy, University of Tuscia, I-01100 Viterbo (Italy)

Giorgia Agresti

Department of Cultural Heritage Sciences, University of Tuscia , I-01100 Viterbo (Italy)

Corresponding author

Paper Info

Citation

Lo Monaco A, Calienno L, Pelosi C, Balletti F, Agresti G, Picchio R (2015). Technical properties of beech wood from aged coppices in central Italy. iForest 8: 82-88. - doi: 10.3832/ifor1136-007

Academic Editor

Giorgio Matteucci

Paper history

Received: Sep 23, 2013

Accepted: Feb 15, 2014

First online: Jun 04, 2014

Publication Date: Feb 02, 2015

Publication Time: 3.63 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2015

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 57516

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 47471

Abstract Page Views: 4034

PDF Downloads: 4368

Citation/Reference Downloads: 36

XML Downloads: 1607

Web Metrics

Days since publication: 4260

Overall contacts: 57516

Avg. contacts per week: 94.51

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

Total number of cites (since 2015): 25

Average cites per year: 2.27

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Research Articles

Hardness and contact angle of thermo-treated poplar plywood for bio-building

vol. 14, pp. 274-277 (online: 29 May 2021)

Research Articles

Kinetic analysis of poplar wood properties by thermal modification in conventional oven

vol. 11, pp. 131-139 (online: 07 February 2018)

Research Articles

Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal

vol. 10, pp. 669-679 (online: 11 July 2017)

Research Articles

The physicomechanical and thermal properties of Algerian Aleppo pine (Pinus halepensis) wood as a component of sandwich panels

vol. 15, pp. 106-111 (online: 21 March 2022)

Research Articles

Mechanical and physical properties of Cunninghamia lanceolata wood decayed by brown rot

vol. 12, pp. 317-322 (online: 06 June 2019)

Research Articles

Physical and mechanical characteristics of poor-quality wood after heat treatment

vol. 8, pp. 884-891 (online: 22 May 2015)

Short Communications

Effect of intensive planting density on tree growth, wood density and fiber properties of maple (Acer velutinum Boiss.)

vol. 9, pp. 325-329 (online: 22 October 2015)

Research Articles

Characterization of technological properties of matá-matá wood (Eschweilera coriacea [DC.] S.A. Mori, E. odora Poepp. [Miers] and E. truncata A.C. Sm.) by Near Infrared Spectroscopy

vol. 14, pp. 400-407 (online: 01 September 2021)

Research Articles

Testing common hornbeam (Carpinus betulus L.) acetylated with the Accoya method under industrial conditions

vol. 10, pp. 948-954 (online: 19 December 2017)

Research Articles

Improving sustainability in wood coating: testing lignin and cellulose nanocrystals as additives to commercial acrylic wood coatings for bio-building

vol. 14, pp. 499-507 (online: 11 November 2021)

iForest Database Search

Search By Author

Search By Keyword

Google Scholar Search

Citing Articles

Search By Author

Search By Keywords

PubMed Search

Search By Author

Search By Keyword