Testing common hornbeam (Carpinus betulus L.) acetylated with the Accoya method under industrial conditions

iForest - Biogeosciences and Forestry, Volume 10, Issue 6, Pages 948-954 (2017)

doi: https://doi.org/10.3832/ifor2359-010

Published: Dec 19, 2017 - Copyright © 2017 SISEF

Research Articles

Collection/Special Issue: COST action FP1407

Understanding wood modification through an integrated scientific and environmental impact approach

Guest Editors: Giacomo Goli, Andreja Kutnar, Dennis Jones, Dick Sandberg

Abstract

Hornbeam wood is known for its high density, hardness, toughness, and wear resistance, but due to its low durability (Class 5 according to EN 350), limited wood quality, and rather small sawmill yield, it is mainly utilized as firewood today. The potential for hornbeam to be used as solid, high-quality wood material exists if its durability and dimensional stability can be increased. Hornbeam boards were acetylated under industrial conditions and tests were carried out to evaluate the treatability of this wood species by acetylation. In this study, the examination of physical, mechanical, and durability properties of acetylated hornbeam wood are described and compared to untreated hornbeam and to acetylated beech, which has a similar anatomical structure to hornbeam. Acetylated hornbeam was also compared to acetylated radiata pine, which is the main product of Accsys Technologies. These comparisons include the determination of the equilibrium moisture content, density, dimensional stability, accelerated checking, color change, water uptake, decay resistance, compression strength, modulus of rupture (MOR), modulus of elasticity (MOE), impact bending strength, Janka hardness, Brinell hardness, and impact bending strength. The aim of this project is the creation of a new product thereby widening the usage of this species.

Keywords

Hornbeam, Acetylation, Accoya, Physical Properties, Mechanical Properties, Durability, Color

Introduction

Acetylation is a chemical modification process that has been studied by scientists around the world for almost 90 years ([16]). A pilot plant was built in the Netherlands in 2004, and after 3 years a large-scale commercial facility was constructed in 2007 and the production of acetylated wood began. Acetylated wood is now specified and used globally in residential and commercial applications.

During acetylation, acetic anhydride is used as a dehydrating agent. The hydroxyl groups are replaced by acetyl groups, which results in dimensionally stable wood. There are many characteristics of wood (like extractives, sample parameters, moisture, density, permeability and wood quality) and treatment settings (like catalysts, purity of the anhydride, initial moisture content, temperature, pressure, etc.) that influence the final products’ properties. After acetylation, the samples are taken for chemical quality assurance and the weight percentage gain is calculated (WPG).

The dimensional stability or anti-swelling efficiency (ASE) is produced by wood cell wall bulking. At 20% WPG, an impressive 70% ASE is found. This means that wood modified to a WPG of 20% will shrink and swell by about one-fourth of the amount exhibited with the same unmodified wood, which is a significant improvement. However, under normal service conditions the actual absolute swelling and shrinkage would be far less since wood in service is never oven dried for two days at 103 °C and then immersed continuously in water for five days ([17]). Cell wall bulking leads to smaller equilibrium moisture content (EMC) and swelling.

These phenomena were experienced by many researchers. The decrease in EMC was observed in acetylated beech, poplar, Scots pine, radiata pine ([2], [30]), and black locust ([30]).

The increased WPG enables better ASE in acetylated radiata pine, southern pine, ponderosa pine, hard maple, walnut, elm, cativo, eucalyptus ([40], [32]), beech ([25]), pine ([22], [38]), rubberwood ([37]), poplar, willow ([32]), black locust ([30]), and flakeboards ([41]). Nevertheless, this is not applicable to every species. For example, red oak and teak had weak ASE despite the high WPG ([40]).

As the weight percentage increases, density also increases in acetylated beech, poplar, Scots pine, radiata pine ([2], [30]), and black locust ([30]).

In the cases of poplar and black locust wood, Németh et al. ([30]) observed that the lightness (L*) decreased, the red hue (a*) increased, and the yellow hue (b*) decreased after acetylation.

Acetylated material is far more resistant against any biological attack. It is the WPG rather than OH substitution that determines the degree of decay resistance ([18]). Many studies have been performed using laboratory pure culture tests, sterile and non-sterile laboratory soil burial tests, and long-term outdoor exposure tests that showed the optimal WPG above which hardly any microbial degradation (usually weight loss) of the wood occurs. It cannot be extrapolated which WPG is sufficient against any biological attack in wood species, but it can be concluded that the higher the level of acetylation, the higher the durability will be. Multiple scientific papers have proven a direct link between acetyl content and wood durability ([36], [20], [1], [31], [42], [23]), but there are also other influential factors like water uptake, density, anatomy, etc. According to Militz ([26]), beech resisted brown and white rot fungi at 20% WPG. It needs 12% WPG against Coriolus versicolor, 20% WPG against Poria placenta, 17% WPG against Coniophora puteana and Gloeophyllum trabeum, and 10% WPG against soft rot decay ([1]).

Acetylation increases the weight of wood, which also increases wood density giving it higher compression strength and hardness properties. This phenomenon is more prominent in saturated wood as the acetylation-induced moisture content reduction in turn increases the tensile strength, the modulus of rupture (MOR), and the modulus of elasticity (MOE). Some cell wall degradation may occur due to the enhanced heat and pressure as well as the presence of acetic acid ([17]). According to the scientific literature, it is unclear how acetylation affects mechanical properties; some scientists report an increase in strength ([9], [45], [22], [38], [30]), some report unaffected properties ([9], [24], [22], [34]), and others a slight decrease in strength ([29], [9], [19], [33], [35]). It should be noted that these results were obtained in lab scale tests and were not optimized on industrial scale.

Hornbeam (Carpinus betulus L.), which is known for its high density, hardness, toughness and wear-resistance, was chosen for this study. It is mainly used as firewood (50-60% in Hungary) because of its limited durability and defects like twisted grain and ridged trunk (which gives small yield). If its durability and dimensional stability can be improved, it has the potential to be used for high added value applications, such as decking and fencing. To our knowledge, no scientific paper concerning the acetylation of hornbeam wood exists.

The aim of this study was to perform a variety of tests on untreated and acetylated hornbeam wood (from the same area of origin) and offer conclusions and suggestions regarding the feasibility of this product. If the results are promising, the process can be optimized for hornbeam; thus, a new product group for outdoor usage can be developed and the usage of the wood species can be widened as well.

Material and methods

Wood material

Twenty pieces of edged and air-dry boards were ordered from a Hungarian sawmill. Their dimensions were 28 × 160 × 2500 mm3 (T x W x L). The wood was from the southwest part of Hungary. Half of the boards were put aside as untreated control specimens and the other half were transported to Accsys Technologies (Netherlands).

Acetylation

Before acetylation, the dimensions were measured with a measuring tape (± 0.5 mm) and a caliper (± 0.01 mm). The moisture content was determined with an electrical resistance moisture meter equipped with insulated electrodes according to EN-13183-2 ([11]). The weight was specified using a laboratory scale (± 0.01 g). The boards’ density and moisture content had low variation, which was ideal for the acetylation process. Prior to acetylation, the boards were pre-dried at the sawmill (ca. 30-40%) following standard protocols, then dried with a convection dryer to a 12% moisture content. The acetylation process took place under industrial conditions.

Weight percentage gain (WPG)

There were no twists or cracks observed on the boards after acetylation. The WPG of ten boards was calculated.

Physical properties

The EMC and density were measured in every test according to DIN-52183 ([4]) and DIN-52182 ([3]), respectively. The shrinkage (β) and anti-swelling efficiency (ASE) were defined according to DIN-52184 ([5]) using 50 samples in each case.

The maximum water uptake after 49 days was determined on 50 samples in each case according to EN-927-5 ([14]). The absorption and desorption cycle were examined in a floating and submersion test for 144 hours according to a research paper of Van Acker et al. ([43]). A silicone sealant (Ceresit CS24® universal silicone, Killich, Czech Republic) was used to seal the edges.

The color was expressed in CIE L*a*b* and CIE L*C*h color system. The color of one untreated and two treated pieces of wood were measured using a CM-2600d® spectrophotometer (Konica Minolta, Tokyo, Japan) with the help of Spectramagic NX program. The colorimeter’s sensor head was 3 mm. The color was measured and calculated based on the D65 illuminant and 10° standard observer. Color measurements were done on the side surfaces with 30 measurement points on each side. The color change for depth was determined in 8 cycles. A cycle here refers to the following: after the color measurement of a surface, the surface was planed (approx. 1-1.5 mm). This process was repeated 8 times and allowed the color change and homogeneity to be examined across the surface and the depth.

Durability

A non-industrial accelerated checking test was performed according to a house method to determine how prone the wood is to develop checks. Before the test, 20 cm long pieces were cut from each board (10 untreated and 10 acetylated) and each was examined for splits or checks. The surfaces were marked to indicate the bark (B) and heart (H) sides. Thereafter, the samples were submerged in water at room temperature for 24 hours. Immediately after the water stage, the samples were placed in an oven at 40 °C and the temperature was increased to as high as 103 °C until constant mass was achieved. The pieces were observed for checks and splits on the surface after drying.

Fungi resistance was determined according to EN-113 ([10]) where the samples were exposed to Coniophora puteana and Poria placenta brown rot fungi, and Coriolus versicolor white rot fungus for 16 weeks. The culture medium was prepared from malt agar (malt extract agar 1.05398.0500, Kenilworth, Merck, NJ, USA). There were 11 Kolle flasks with reference samples for each fungus, with one untreated and one acetylated sample, and there were 2-4 flasks with virulence control specimens.

Mechanical properties

The compression strength parallel to the grain was determined according to DIN-52185 ([6]) using 50 samples in each case. The bending strength and MOE were measured on dry and water-saturated specimens (50 samples in each case) according to DIN-52186 ([7]). When the specimen was put in the test machine, the loading head pressed the tangential face of the sample so that it was perpendicular to the annual rings.

The impact bending strength was determined according to DIN-52189-1 ([8]) using 50 samples in each case. The test piece was put in the Charpy impact test machine so that the hammer encountered the radial section and knocked through the tangential section. The specimens all broke into two pieces during the tests.

Janka hardness was determined in every anatomical direction, on dry and water-saturated specimens according to ISO-3350 ([21]) with different dimensions. The specimens were 50 mm wide, 50 mm long and only 25 mm thick instead of the desired 50 mm due to the thinness of the available material. This difference in size can affect the results because the big loading head caused the samples to crack more easily. There were 50 untreated samples, but only 25 acetylated samples.

Brinell hardness was determined in every anatomical direction, on dry and water-saturated specimens according to EN-1534 ([12]) with different dimensions (50 samples in each case). Similarly, the specimens were 50 mm wide, 50 mm long, and only 25 mm thick instead of 50 mm due to the thinness of the available material. In this case, the sample size does not affect the results because of the small indentation. The indentation points were distributed randomly. 500 N was applied during the test as it is a European wood species.

Results and discussion

Weight percentage gain (WPG)

The WPG ranged between 13.6% and 16.5%, having an average of 15.3%. The WPG level indicated that the wood was successfully impregnated.

Equilibrium moisture content and density

Hornbeam was unable to absorb as much moisture in an acetylated state as it can in a natural state. EMC values decreased by 70% after acetylation and the fiber saturation point (FSP) was 35% lower. Due to weight gain, density changed by 16% in the dry state, 8% in the conditioned state, and 4% in the saturated state (Tab. 1).

Tab. 1 - Physical properties of untreated and acetylated hornbeam, beech and radiata pine; values in brackets are standard deviations. Literature data: (MB): Molnár & Bariska ([28]); (AT): Accsys Technologies (Netherlands); (W): Wagenführ ([44]).

| Property | Parameter | Hornbeam | Beech | Radiata pine | |||

|---|---|---|---|---|---|---|---|

| Acetylated | Control | Acetylated | Control | Acetylated | Control | ||

| Moisture content (%) |

Fiber saturation point | 24 (2.3) | 37 (1.9) | - | 32-35 MB | - | - |

| Equilibrium at 20 °C 65% | 3 (0.3) | 10 (0.5) | - | - | - | - | |

| Density (kg m-3) |

Dried | 801 (66.3) | 689 (15.9) | - | 680 W | - | 400 W |

| Conditioned | 823 (53.6) | 761 (53.5) | 800 AT | 720 W | 510 AT | 510 W | |

| Saturated | 982 (58.2) | 942 (35.5) | - | 1070 W | - | 800 W | |

| Shrinkage (%) |

Radial | 1.17 (0.47) | 6.46 (0.67) | 1.3 AT | 5.9 AT | 0.7 AT | 2.3 W |

| Tangential | 2.04 (0.83) | 10.86 (0.80) | 2.2 AT | 12.9 AT | 1.5 AT | 4.5 W | |

| Longitudinal | 0.32 (0.20) | 0.42 (0.30) | - | 0.3 MB | - | 0.3 W | |

| Max. water uptake (g m-2) | 4559 (1035) | 5513 (1137) | 5600 AT | - | 23442 AT | - | |

Shrinkage, dimensional stability

Tangential shrinkage was 41% greater than radial shrinkage in untreated samples and 43% greater in treated samples (Tab. 1). The shrinkage values of acetylated samples were lower than shrinkage values of untreated samples; the values were 81%, 82%, and 24% lower in the tangential, radial, and longitudinal directions, respectively. This is related to the increased ASE, which was measured from the saturated to dried state, and from the conditioned (20°C 65%) to dried state, which resulted in 81% and 88% ASE, respectively.

Water uptake

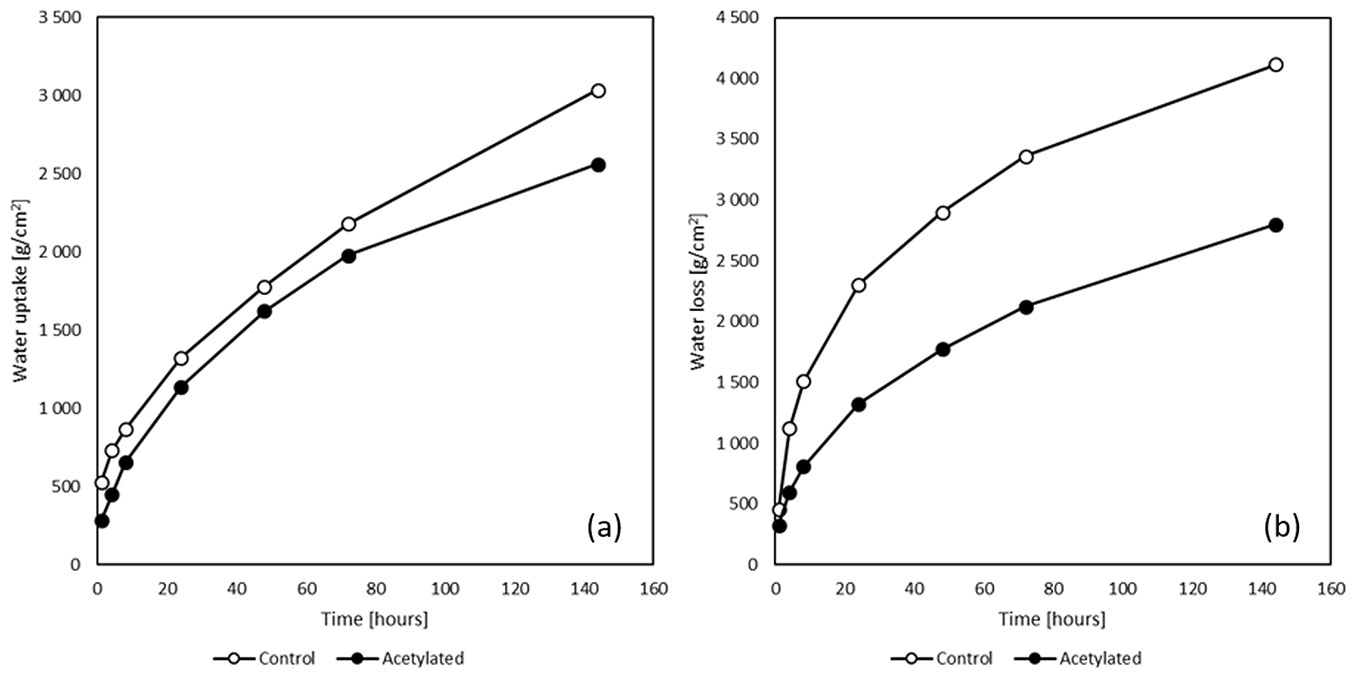

In connection with the moisture content reduction, the acetylated specimens had 17% lower water uptake/loss values (Tab. 1). Fig. 1 shows the rate of water uptake (a) and water loss (b) after 144 hours.

Compared to acetylated beech and acetylated radiata pine, acetylated hornbeam had 18% and 80% lower water uptake after 49 days, respectively (Tab. 1).

This change of hygroscopicity indicates that acetylated hornbeam has lower hysteresis and lower sorption isotherms than natural hornbeam ([15]). In order to prove this hypothesis, further tests need to be carried out regarding the sorption behavior of acetylated hornbeam. This can be useful in applications like parquet, decking, or façades where the wood is exposed to water and frequently changing humidity.

Accelerated checking

Due to forced moisture and temperature changes, the untreated hornbeam samples discolored, warped, cracked, and developed internal checks and fiber cell collapses. None of the untreated samples remained intact; cracks appeared on both sides as well as on the end grain. On the contrary, the acetylated samples were more dimensionally stable; only a few hairline cracks appeared because of the accelerated desorption. There were no detectable differences in appearance between the heart and bark side of the board.

Color measurements

The darkening of acetylated wood highly depends on the reaction conditions and the catalyst used (pyridine, dimethylformamide, etc.), and of course on the wood species (chemical structure, permeability) itself ([39]). Hornbeam is a highly permeable, diffuse-porous species that is suitable for acetylation.

Natural hornbeam has wavy grain because of its growing pattern, but this look is more prominent when it is acetylated. Besides this, there were stains because of condensed water on the boards as a result of drying, but these were removed by the first planing. During the acetylation process, the reagent could fully penetrate the wood. There was no envelope effect, just 1-2 mm thick, darker crusting where the acetyl content is the highest. Internal cracks were observed on the acetylated samples as they were taken from the end of the boards where wood moisture desorption is more intensive.

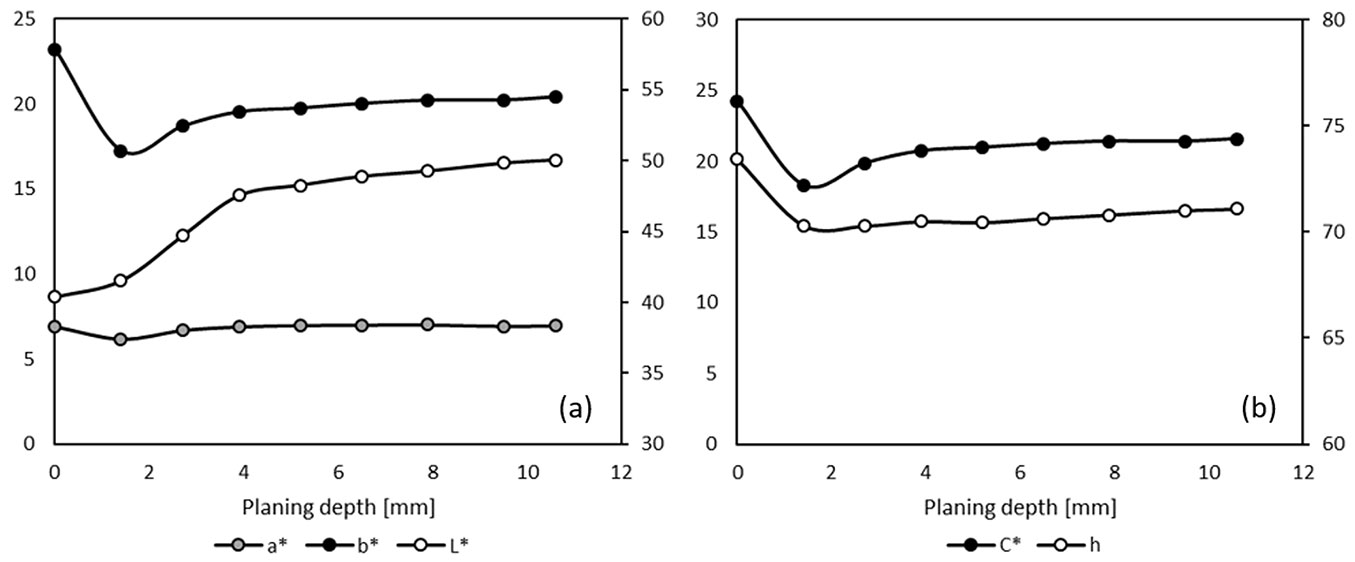

The test results show that going deeper into the wood, the surface color becomes more homogenous (ΔE* decreases) even though the sticker marks fade away only after 4-5 mm (Fig. 2). After acetylation, the lightness decreased, the red hue increased, and the hue decreased. As shown in Tab. 2, it gained a greyish-brown color, which differs from natural hornbeam or beech, but is similar to walnut (Juglans spp.) or mutenye (Guibourtia arnoldiana - [27]).

Fig. 2 - Color properties of acetylated hornbeam surfaces in different depths. (L*): lightness; (a*): red hue; (b*): yellow hue; (h): hue; (C*): chroma.

Tab. 2 - Color properties of acetylated hornbeam, hornbeam and some similar wood species ([27]). (L*): lightness; (a*): red hue; (b*): yellow hue; (h): hue; (C*): chroma; (ΔE*): color difference of each species is compared to acetylated hornbeam.

Fungi resistance

Acetylation greatly improved the fungi resistance of hornbeam, as can be seen in Tab. 3. It lost less than 1% of its weight when exposed to three different fungi. When the untreated specimen was accompanied by an acetylated specimen, the untreated sample lost less weight than the virulence samples because of the reagent’s presence in the flask. In some cases, the fungi could not degrade the wood material because of the appearance of mold; these samples were excluded from the results. In the case of Poria placenta, 4 out of 9 acetylated samples showed negative weight loss, which were changed to zero according to standard.

Tab. 3 - Weight loss of untreated and acetylated samples exposed to wood-decay fungi for 16 weeks. Values are means ± standard deviation.

| Fungus | Vessel | Sample | Weight loss (%) |

|---|---|---|---|

| Coniophora puteana | Virulence | Control | 45.64 ± 3.68 |

| Reference | Control | 18.58 ± 1.07 | |

| Acetylated | 0.84 ± 0.17 | ||

| Poria placenta | Virulence | Control | 20.78 ± 1.54 |

| Reference | Control | 21.19 ± 6.61 | |

| Acetylated | 0.20 ± 0.21 | ||

| Coriolus versicolor | Virulence | Control | 34.00 ± 1.91 |

| Reference | Control | 32.66 ± 2.09 | |

| Acetylated | 0.83 ± 0.12 |

Coniophora puteana attacks both softwood and hardwood but has a preference for conifers. In the case of virulence samples, the fungi successfully decayed the material, but when the samples were mixed, the reference controls were more prone to mold attack.

Poria placenta attacks primarily conifers, but the weight loss values (20.78%) indicate that the test was successful (in the case of conifers it would have been around 35-40%). The mold is also present in many instances, and the deviation is larger than in the cases of the other two fungi.

Coriolus versicolor attacks primarily broadleaved species, which explains the small deviation and the scarce appearance of mold (which could not hinder the decaying process). In this case, there is only a small difference between the virulence and reference untreated samples.

Compression strength parallel to the grain

Due to acetylation, hornbeam gained a harder and denser structure, which provided 43% higher compression strength properties. As seen in Tab. 4, its structure is still less homogenous than the untreated wood, resulting in higher deviation in the results. During the test, a greater number of samples were cloven due to the denser structure.

Tab. 4 - Strength and elasticity properties of untreated and acetylated hornbeam, beech and radiata pine; values are means ± standard deviation. Literature data: (MB): Molnár & Bariska ([28]); (AT): Accsys Technologies (Netherlands); (W): Wagenführ ([44]).

| Property | Hornbeam | Beech | Radiata pine | ||||

|---|---|---|---|---|---|---|---|

| Acetylated | Control | Acetylated | Control | Acetylated | Control | ||

| Compression strength parallel to grain (N mm-2) | 84.0 ± 6.6 | 59.0 ± 4.3 | - | 62 MB | - | 51 W | |

| Modulus of rupture (N mm-2) | Conditioned | 173.0 ± 25.2 | 144.0 ± 9.8 | 114 AT | 127 AT | 39 AT | 78 W |

| Saturated | 141.0 ± 15.2 | 73.0 ± 6.4 | 107 AT | 60 AT | - | - | |

| Modulus of elasticity (kN mm-2) | Conditioned | 15.4 ± 1.5 | 15.4 ± 1.2 | 12.15 AT | 13.03 AT | 8.79 AT | 11 W |

| Saturated | 14.1 ± 1.4 | 10.4 ± 1.0 | 11.68 AT | 7.81 AT | - | - | |

| Impact bending strength (kJ m-2) | 159.0 ± 37.0 | 84.0 ± 10.8 | - | 100 MB | 50 AT | 94 W | |

MOR and MOE

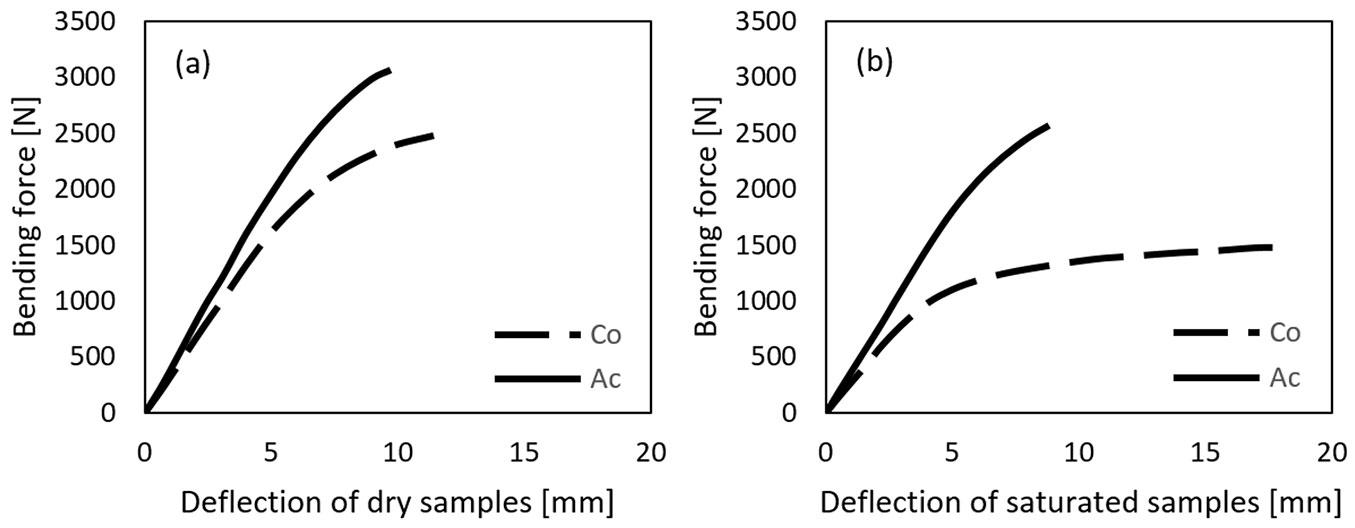

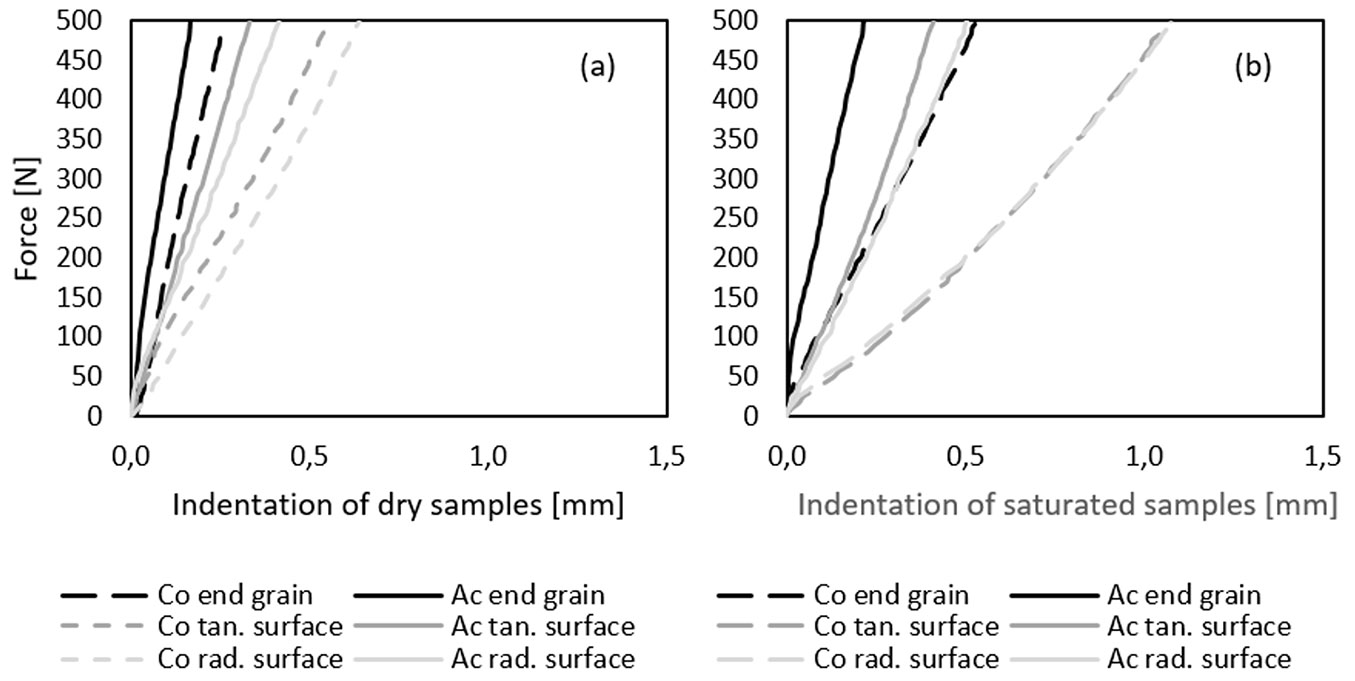

During the bending test of the dry samples, the untreated and acetylated samples gave different fractures. Most of the samples broke on the outer side where tension stress was induced. In some cases, the sample had skewed grain, which resulted in weaker bending strength (<100 MPa). The difference in strength and flexibility is also reflected in the way the samples broke: the untreated samples had brittle fractures while the acetylated samples had stiff fractures (Fig. 3a). It took more time to bend the saturated untreated hornbeam samples than it did to bend the treated ones, because unsaturated untreated hornbeam became very soft, which leads to weaker bending strength and smaller MOE (Fig. 3b). Meanwhile, the acetylated samples did not absorb as much water, so their properties did not decrease as much (Tab. 4). After acetylation, the MOR of dry and saturated samples increased by 20% and 93%, respectively. The MOE of saturated samples increased by 36%.

Fig. 3 - Fracture diagram of control (Co) and acetylated (Ac) hornbeam samples according to bending tests.

Impact bending strength

Due to the increased density and hardness, hornbeam had 88% higher impact bending strength after acetylation. This is also reflected in the way the samples broke - untreated hornbeam had brittle, clean breaks while acetylated hornbeam had stiff, splintery fractures after impact. The treated material tends to have an inhomogeneous structure and sometimes lower dynamic loading properties because of the cell wall degradation caused by acetylation. Hornbeam tends to have a twisted or wavy grain, which needs to be taken into account during sample production. These wood defects are caused by natural growth and not hornbeam-specific settings used in the acetylation process, which can explain the high deviation of the results (Tab. 4).

Janka hardness

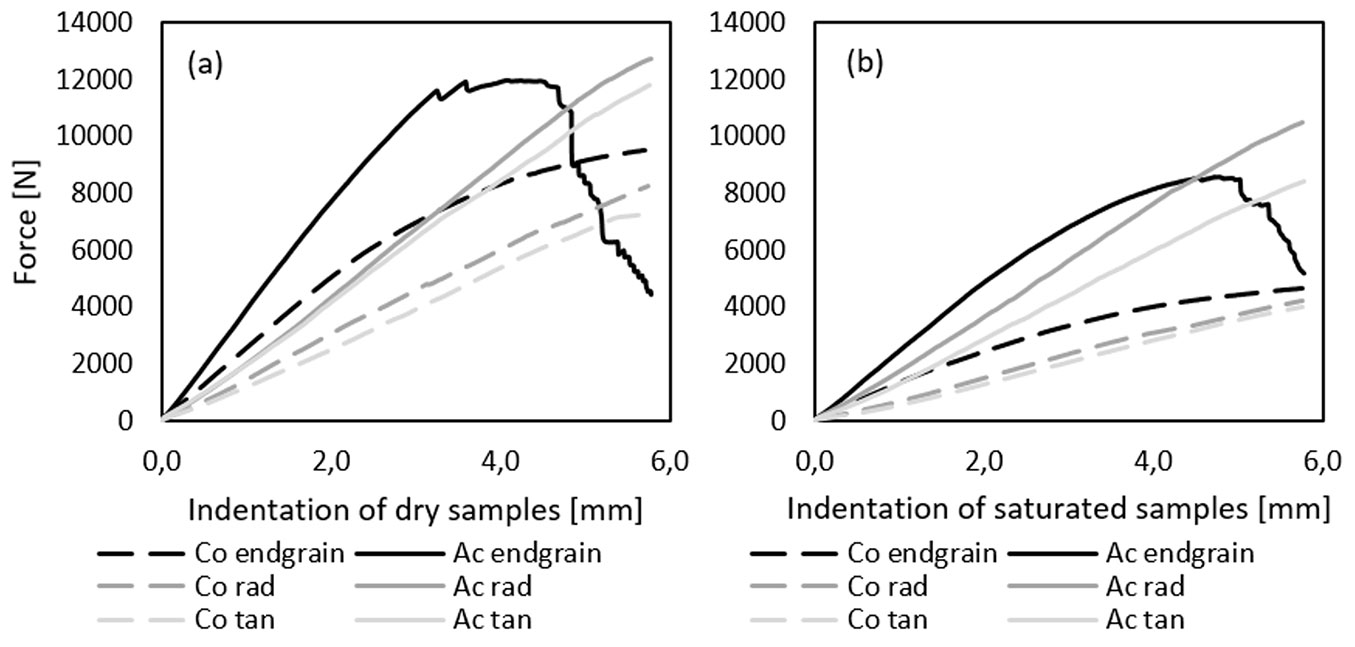

The Janka hardness of the tangential surface was 9% higher than in tangential direction in both untreated and acetylated samples. After saturation, this difference increased to 26% for untreated samples and decreased to 4% for acetylated samples. However, cracks tend to appear across the pith rays when the tangential surface is tested.

After acetylation, the tangential and radial surfaces’ hardness increased by 55% and 56%, respectively, whereas in the saturated samples, these increased by 154% and 111%, respectively (Fig. 4, Tab. 5). The radial surface hardness of untreated samples decreased by 46% after saturation and the radial surface hardness decreased by 49%. As for the acetylated samples, the same values decreased by 27% and 16%, respectively (Tab. 5).

Fig. 4 - Force-indentation diagrams of Janka hardness tests. Control (Co) and acetylated (Ac) samples.

Tab. 5 - Hardness properties of untreated and acetylated hornbeam, beech and radiata pine. Values are means ± standard deviation. Literature data: (MB): Molnár & Bariska ([28]); (AT): Accsys Technologies (Netherlands); (W): Wagenführ ([44]);

| Property | Hornbeam | Beech | Radiata pine | ||||

|---|---|---|---|---|---|---|---|

| Acetylated | Control | Acetylated | Control | Acetylated | Control | ||

| Janka hardness (conditioned) (N mm-2) |

Radial | 114 ± 17.9 | 73 ± 4.8 | 79 AT | 71 AT | 41 AT | 28 AT |

| Tangential | 124 ± 21.4 | 80 ± 6.8 | - | - | 42 AT | 28 AT | |

| End grain | - | 95 ± 7.3 | 107 AT | 84 AT | 66 AT | 36 AT | |

| Janka hardness (saturated) (N mm-2) |

Radial | 83 ± 10.9 | 39 ± 2.9 | - | - | - | - |

| Tangential | 105 ± 15.3 | 41 ± 5.7 | - | - | - | - | |

| End grain | - | 46 ± 3.5 | - | - | - | - | |

| Brinell hardness (conditioned) (N mm-2) |

Radial | 39 ± 5.6 | 26 ± 2.4 | - | 34 MB | - | 13 W |

| Tangential | 50 ± 9.1 | 29 ± 2.7 | - | 34 MB | - | 13 W | |

| End grain | 101 ± 12.7 | 67 ± 10.4 | - | 72 MB | - | - | |

| Brinell hardness (saturated) (N mm-2) |

Radial | 32 ± 4.7 | 14 ± 1.2 | - | - | - | - |

| Tangential | 40 ± 7.8 | 15 ± 1.5 | - | - | - | - | |

| End grain | 74 ± 15.8 | 30 ± 3.1 | - | - | - | - | |

During the Janka hardness test of the end grain, the acetylated samples broke; those measurements are not included in the results. As a side note, Fig. 4 shows the maximum force to have a tendency above 10-12 kN.

Brinell hardness

The Brinell hardness of the tangential surface was 28% higher than the radial surface in the acetylated samples and 13% higher in the untreated samples. After saturation, this difference decreased to 25% for the acetylated samples and 7% for the untreated samples (Fig. 5).

Fig. 5 - Force-indentation diagrams of Brinell hardness tests of control (Co) and acetylated (Ac) samples.

After acetylation, the hardness values increased by 49%, 68% and 51% on the radial, tangential and end grain surface, respectively. With the saturated samples, the hardness values were 124%, 163%, and 145% higher on the radial, tangential and end grain surface compared to natural hornbeam. The hardness of untreated samples decreased after saturation by 46%, 48%, and 55% on the radial, tangential surface and end grain, respectively. As for the acetylated samples, the same values decreased by 18%, 19% and 26%, respectively. The high deviation in the results indicates inhomogeneity within the wood, but this can be explained by not hornbeam-specific acetylation settings and the relatively small testing surface used during the Brinell hardness test (Tab. 5).

Conclusions

During the acetylation process, the cell walls of hornbeam became bulked due to the reaction between the hydroxyl groups of the cell wall and the acetic anhydride. Acetyl groups replaced the OH groups, which are responsible for the swelling and shrinkage of wood. As a result, hornbeam became less sensitive to moisture than it had been before. This is confirmed by our results, as the EMC, FSP, shrinking rate, and water uptake decreased and the ASE increased.

Acetylated samples showed a lower tendency to crack than natural hornbeam, which can also be explained by the bulking effect.

Due to acetylation, hornbeam’s color darkened, became less homogenous, and developed a wavy figure. According to the color measurement, lightness (L*) decreased, red hue (a*) increased, while the yellow hue (b*) remained unchanged, the hue (h) slightly increased and the chroma (C*) slightly increased. Thus, the color turned a more reddish, grayish brown, similar to the color of walnut.

Acetylation prevented all three fungi species from attacking hornbeam, which in its natural state is a non-durable wood species (Class 5 according to [13]). After being exposed to fungi for 16 weeks, the treated samples’ weight loss was below 1%, which makes it a very durable material (Class 1 according to [13]). The presence of the acetylated material also had an impact on the reference samples, as fungi decayed these less than the virulence specimens.

It is difficult to state clearly how acetylation affects the mechanical properties of every wood species because there are many mechanisms that take place. On one hand, the capability of wood to absorb moisture decreases, which can influence the mechanical properties positively; also, the properties do not weaken as drastically as in the case of untreated wood during soaking. The density also increases as a result of the weight percentage gain. On the other hand, as the wood swells because of the acetyl groups, there will be fewer fibers in the cross section, which can decrease the mechanical properties. If the right settings are used for each wood species, the positive and negative effects can be kept in balance or tilted in the positive direction depending on the field of use and the properties to be improved. In the case of hornbeam wood, every mechanical property increased, which is very promising even though there were many instances of high variation in the results. Acetylated hornbeam showed even higher strength and hardness properties than those of acetylated beech and radiata pine.

Hornbeam, in its natural form, is a non-durable wood species with a strong, hard, dense, tough and wear-resistant structure. Its sensitivity to moisture and low durability has hindered its use outdoors, but with acetylation it became a denser, less moisture-sensitive, more dimensionally stable and more durable material. In addition to acetylated beech and radiata pine, it could become a raw material for many indoor and outdoor products that are exposed to varying humidity, fungi, and heat load, such as decking, marine decking, fencing, outdoor stairs, furniture, handrails, etc. After these promising research findings, further examinations that will focus on the optimization of the acetylation treatment of hornbeam are planned. In addition, other tests are being considered regarding behavior to other exposures like surface treatability and bonding, and technological properties like corrosion resistance and workability.

Acknowledgements

We thank Accsys Technologies (Arnhem, the Netherlands) for their cooperation and support in the acetylation process and for sharing their experience and ideas. We also thank the colleagues at the Institute of Wood Science in Sopron (Hungary) who helped during the measurements.

References

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Authors’ Info

Authors’ Affiliation

Róbert Németh

Institute of Wood Science, Simonyi Karoly Faculty of Engineering, Wood Sciences and Applied Arts, University of Sopron, Bajcsy-Zs. u. 4. H-9400 Sopron (Hungary)

Accsys Technologies PLC group, 6802 CC Arnhem (Netherlands)

Corresponding author

Paper Info

Citation

Fodor F, Lankveld C, Németh R (2017). Testing common hornbeam (Carpinus betulus L.) acetylated with the Accoya method under industrial conditions. iForest 10: 948-954. - doi: 10.3832/ifor2359-010

Academic Editor

Giacomo Goli

Paper history

Received: Jan 17, 2017

Accepted: Sep 25, 2017

First online: Dec 19, 2017

Publication Date: Dec 31, 2017

Publication Time: 2.83 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2017

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 49585

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 40576

Abstract Page Views: 3573

PDF Downloads: 4336

Citation/Reference Downloads: 15

XML Downloads: 1085

Web Metrics

Days since publication: 2993

Overall contacts: 49585

Avg. contacts per week: 115.97

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

Total number of cites (since 2017): 13

Average cites per year: 1.44

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Research Articles

Mechanical and physical properties of Cunninghamia lanceolata wood decayed by brown rot

vol. 12, pp. 317-322 (online: 06 June 2019)

Research Articles

Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal

vol. 10, pp. 669-679 (online: 11 July 2017)

Research Articles

Physical-mechanical properties and bonding quality of heat treated poplar (I-214 clone) and ceiba plywood

vol. 8, pp. 687-692 (online: 17 December 2014)

Research Articles

Heat treatment of poplar plywood: modifications in physical, mechanical and durability properties

vol. 16, pp. 1-9 (online: 09 January 2023)

Research Articles

Characterization of technological properties of matá-matá wood (Eschweilera coriacea [DC.] S.A. Mori, E. odora Poepp. [Miers] and E. truncata A.C. Sm.) by Near Infrared Spectroscopy

vol. 14, pp. 400-407 (online: 01 September 2021)

Research Articles

Physical and mechanical properties of particleboards manufactured using charcoal as additives

vol. 10, pp. 70-74 (online: 29 June 2016)

Review Papers

Wood modification technologies - a review

vol. 10, pp. 895-908 (online: 01 December 2017)

Research Articles

Kinetic analysis of poplar wood properties by thermal modification in conventional oven

vol. 11, pp. 131-139 (online: 07 February 2018)

Technical Advances

Technical properties of beech wood from aged coppices in central Italy

vol. 8, pp. 82-88 (online: 04 June 2014)

Research Articles

Reversible and irreversible effects of mild thermal treatment on the properties of wood used for making musical instruments: comparing mulberry to spruce

vol. 15, pp. 256-264 (online: 20 July 2022)

iForest Database Search

Search By Author

Search By Keyword

Google Scholar Search

Citing Articles

Search By Author

Search By Keywords

PubMed Search

Search By Author

Search By Keyword