Influence of thermo-vacuum treatment on bending properties of poplar rotary-cut veneer

iForest - Biogeosciences and Forestry, Volume 10, Issue 1, Pages 161-163 (2016)

doi: https://doi.org/10.3832/ifor1955-009

Published: Jun 13, 2016 - Copyright © 2016 SISEF

Short Communications

Abstract

The present paper investigates the influence of thermo-vacuum treatment at 170, 190 and 210 °C on the mechanical and physical properties of poplar wood rotary-cut veneers obtained from two different poplar clones (’I-214’ and ’Lena’). The modulus of rupture in bending was determined according to a method derived from European Standard EN-310 and previously validated by the authors, while the density was determined on the basis of EN-323. With both clones no significant decrease was recorded either in bending strength or in density with treatment temperatures up to 190 °C. On the contrary, at 210 °C a highly significant decrease in modulus of rupture (’I-214’: -18%; ’Lena’: -15%) was recorded; the density showed a similar, though lower, trend (’I-214’: -5 %; ’Lena’: -8.5 %).

Keywords

Populus, Poplar Wood, Veneer, Thermal treatment, Bending Strength

Introduction

Thermal treatment has been applied to wood since the beginning of the last century, when several studies demonstrated that exposing wood to high temperatures reduces its equilibrium moisture content and consequently its dimensional shrinkage ([2], [6]). High-temperature heat treatment is considered a suitable method to improve some wood characteristics. It allows to reduce the amount of toxic chemical applications normally required to increase wood durability and enhances dimensional stability by reducing its hygroscopicity ([10], [11]). Nowadays, heat treatment (HT) is mainly applied to sawn timber, while limited information is yet available about the treatment of wood-based engineered materials, in particular poplar veneers and plywood. In this context, a few recent studies focused on these products: Goli et al. ([7]) investigated the physical mechanical properties of poplar plywood heated in normal conditions of oxygen availability; Lovrić et al. ([9]) studied the influence of thermal modification on the color of poplar veneers; Zdravković et al. ([14]) assessed the dimensional stability of plywood made of thermally modified poplar veneers.

Several HT processes have been developed during the last years; among these, thermo-vacuum treatment is an innovative technology in which reduction of oxygen concentration, necessary to avoid wood combustion, is obtained by creating a vacuum inside the reactor. This method provides several advantages in terms of process efficiency and quality of the material treated ([1]). On the whole, the industrial and scientific interest in thermally treated wood is currently having new impetus due to the growing demand for environmental-friendly construction products ([12], [13]).

In this paper we report the results of a study on the bending properties of poplar rotary-cut veneers to which a thermo-vacuum process was applied at 170 °C, 190 °C and 210 °C. The aim was to determine which process parameters allow to achieve the maximum improvement of performance. In fact, it is well known that while some wood characteristics (e.g., durability, dimensional stability) benefit from thermo-treatment, others (e.g., the mechanical behavior) can be negatively influenced ([6], [8]).

Materials and methods

In this experimental work, veneers of the clones ’I-214’ (Populus × canadensis Moench) and ’Lena’ (Populus deltoides W. Bartam. ex Marshall) were peeled by a plywood factory of established experience, according to its usual industrial practice. For each clone, 4 veneers were chosen among the sheets where growth rings and/or separation between sapwood and false heartwood were clearly visible, in order to evaluate the influence of these anatomical features on the properties of the wood material considered. Veneers were divided into different portions, which were subjected to heat treatment at 170 °C (T1), 190 °C (T2), 210 °C (T3); due to the limited amount of material available, treatment T2 was not performed on the veneers of the clone ’Lena’. Non-treated veneers (T0) were also collected and successively tested as control.

After treatment, all veneers, including non-treated ones, were photographed and a grid was drawn on their surface in order to locate all test pieces which were subsequently cut from the sheet and marked according to their original position. From each sheet portion a set of 36 test pieces was drawn.

As there are no international standards establishing mechanical test methods for veneers, the bending strength of the test pieces (2.5 mm thick, 20 mm wide and 80 mm long) was determined according to a method - based on EN-310 ([4]) - already validated by one of the authors in a previous study ([3]). Due to the high correlation between modulus of elasticity (MoE) and modulus of rupture (MoR) demonstrated ([3]), and in consideration of the simplicity and convenience of determining the latter with the equipment available, only MoR was measured.

The test pieces were conditioned until constant mass was reached in a climatic cell at a temperature of 20 ± 2 °C in an atmosphere with 65 ± 5 % of relative humidity and then subjected to three-point static bending (with a span of 70 mm), to determine their longitudinal Modulus of Rupture (MoR). The tests were carried out using a tensometer particularly suitable for small-size test pieces when the strains to be measured are rather low, by means of a 100 daN load cell. The load was applied with a constant movement rate of the loading head of 5 mm min-1, corresponding to a total time until rupture between 90 s and 120 s.

As for the determination of density, the tests were carried out in conformity with EN-323 ([5]) standard. The dimensions of each test piece were measured using a digital caliper with an accuracy of ± 0.01 mm, while the weight was measured using a scale with an accuracy of ± 0.01 mm.

For both MoR and density, statistical differences among treatments T0, T1, T2 and T3 were investigated through the analysis of variance (ANOVA) using a LSD post-hoc test.

Results and conclusions

Tab. 1 and Tab. 2 report minimum and maximum values, together with standard deviations and mean values, of the bending strength and density determined on test pieces of the clones ’I-214’ and ’Lena’ respectively, cut both from veneers subjected to all treatments and from non-treated ones.

Tab. 1 - Clone ’I-214’: minimum and maximum values of MoR (N mm-2) and density (in g cm-3), together with standard deviation and mean values, of tested veneers.

| Parameter | Statistics | T0 (non treated) |

T1 (170 °C) |

T2 (190 °C) |

T3 (210 °C) |

|---|---|---|---|---|---|

| MoR (N mm-2) |

Min. | 48.39 | 47.73 | 49.95 | 35.21 |

| Max. | 73.06 | 77.48 | 74.87 | 63.30 | |

| St. dev. | 6.64 | 6.25 | 6.35 | 7.17 | |

| Mean value | 62.14 | 62.75 | 62.82 | 50.97 | |

| Density (g cm-3) |

Min. | 0.290 | 0.299 | 0.297 | 0.281 |

| Max. | 0.393 | 0.386 | 0.389 | 0.372 | |

| St. dev. | 0.345 | 0.022 | 0.021 | 0.023 | |

| Mean value | 0.345 | 0.340 | 0.342 | 0.329 |

Tab. 2 - Clone ’Lena’: minimum and maximum values of MoR (N mm-2) and density (in g cm-3), together with standard deviation and mean values, of tested veneers.

| Parameter | Statistics | T0 (non treated) |

T1 (170 °C) |

T3 (210 °C) |

|---|---|---|---|---|

| MoR (N mm-2) |

Min. | 45.83 | 48.46 | 26.15 |

| Max. | 83.60 | 76.71 | 76.65 | |

| St. dev. | 9.84 | 7.08 | 11.52 | |

| Mean value | 61.05 | 62.28 | 51.99 | |

| Density (g cm-3) |

Min. | 0.304 | 0.314 | 0.292 |

| Max. | 0.465 | 0.471 | 0.451 | |

| St. dev. | 0.041 | 0.038 | 0.046 | |

| Mean value | 0.398 | 0.386 | 0.364 |

According to previous researches ([3]), it can be easily seen that the bending strength varies significantly in the different zones of the growth ring. The values determined on early wood are considerably lower than those obtained on latewood: for instance, in the case of ’I-214’ non-treated (T0) veneers the minimum value (48.4 N mm-2), recorded on early wood, is only 43% of the maximum value (73.1 N mm-2) obtained on latewood. Similar differences were also found for all the treatments for both clones.

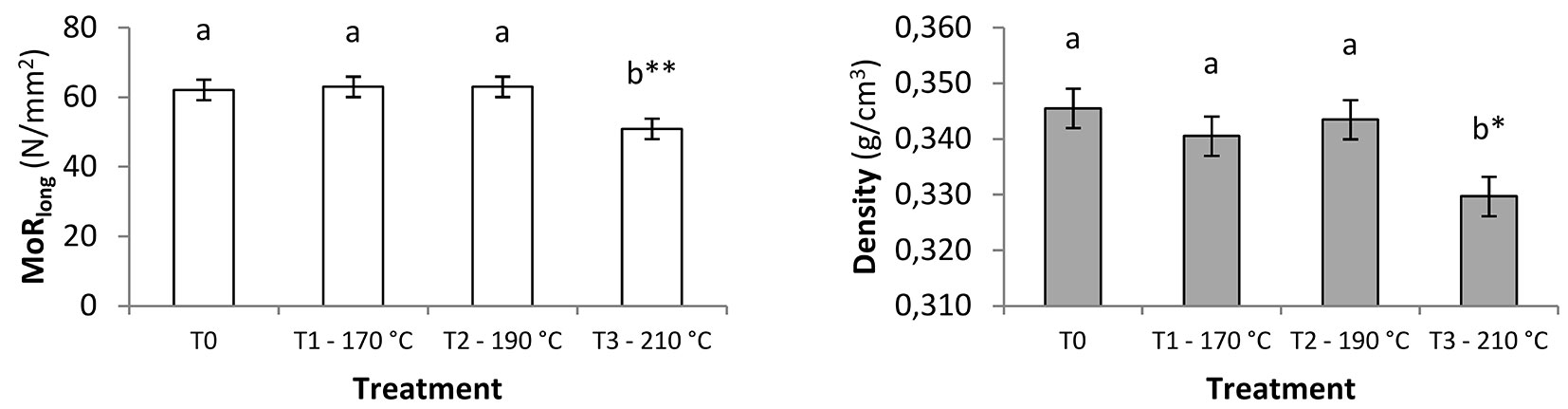

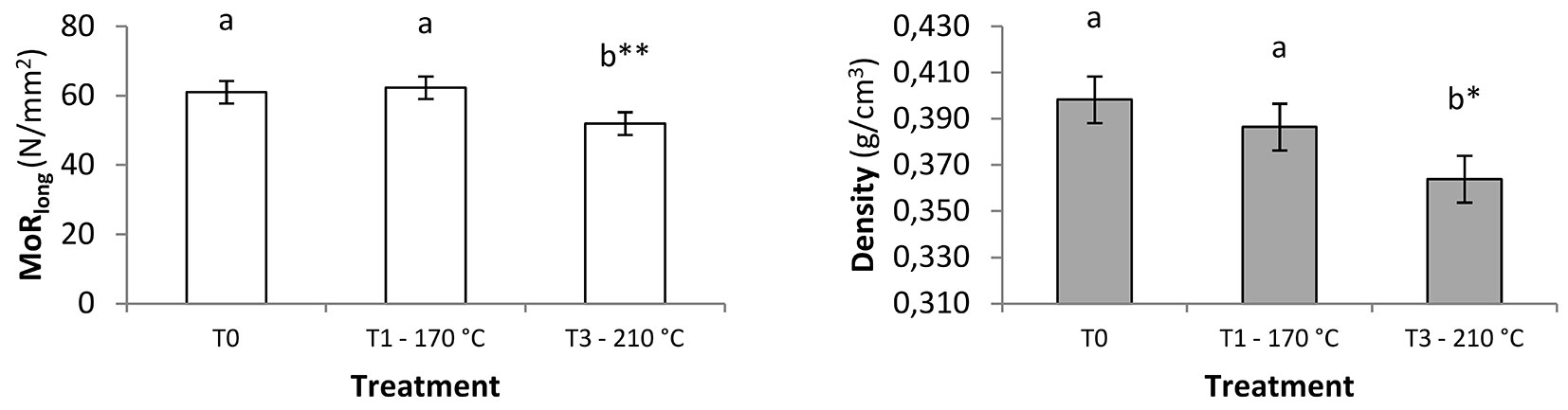

Either for MoR or density, no significant difference was found for both clones among non-treated veneers and veneers treated at 170 °C and 190 °C. Instead, statistically significant differences (p < 0.01 for MoR and p < 0.05 for density) were found between veneers treated at 210 °C and all the other treatments (Fig. 1 and Fig. 2). This behavior, showed both by ’I-214’ and ’Lena’ veneers, indicates that beyond 190 °C a relevant degradation of wood fibre structure occurs, determining an abrupt decrease of bending strength properties. Finally, a high and significant correlation was found by linear regression between density and MoR both for ’I-214’ (R2 = 0.88) and ’Lena’ (R2 = 0.81), confirming the well-known relation between these parameters.

Fig. 1 - Clone ’I-214’: mean values and statistical differences MoR (left) and density (right) determined on veneers subjected to HT T0, T1, T2 and T3. Different letters indicate significant differences after LSD test.(*): p < 0.05; (**): p < 0.01.

Fig. 2 - Clone ’Lena’: mean values and statistical differences MoR (left) and density (right) determined on veneers subjected to HT T0, T1 and T3. Different letters indicate significant differences after LSD test. (*): p < 0.05; (**): p < 0.01.

In conclusion, the results obtained so far suggest that no significant modification in terms of modulus of rupture and density occurs to thermo-vacuum treated poplar veneers up to 190 °C, while at 210 °C these properties decrease significantly. These findings, together with other data on treated veneers such as natural durability and dimensional stability, could allow to develop an effective thermo-vacuum treatment for poplar veneers and plywood. Such a product could be suitable for many applications in exterior environments, particularly as a replacement for panels made with some exotic wood species.

Acknowledgements

This research was part of the project “ThermoPoplarPly”, jointly financed by the European Union, the Italian State and the Piedmont Region under the Rural Development Programme 2007-2013.

References

Authors’ Info

Authors’ Affiliation

Laura Rosso

C.R.E.A. - Unità di Ricerca per le Produzioni Legnose fuori Foresta, Casale Monferrato, AL (Italy)

Corresponding author

Paper Info

Citation

Castro G, Rosso L, Allegretti O, Cuccui I, Cremonini C, Negro F, Zanuttini R (2016). Influence of thermo-vacuum treatment on bending properties of poplar rotary-cut veneer. iForest 10: 161-163. - doi: 10.3832/ifor1955-009

Academic Editor

Giacomo Goli

Paper history

Received: Dec 17, 2015

Accepted: Feb 24, 2016

First online: Jun 13, 2016

Publication Date: Feb 28, 2017

Publication Time: 3.67 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2016

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 49363

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 41770

Abstract Page Views: 2784

PDF Downloads: 3569

Citation/Reference Downloads: 36

XML Downloads: 1204

Web Metrics

Days since publication: 3525

Overall contacts: 49363

Avg. contacts per week: 98.03

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

Total number of cites (since 2017): 2

Average cites per year: 0.22

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Research Articles

The physicomechanical and thermal properties of Algerian Aleppo pine (Pinus halepensis) wood as a component of sandwich panels

vol. 15, pp. 106-111 (online: 21 March 2022)

Research Articles

Thermo-modified native black poplar (Populus nigra L.) wood as an insulation material

vol. 14, pp. 268-273 (online: 29 May 2021)

Research Articles

Kinetic analysis of poplar wood properties by thermal modification in conventional oven

vol. 11, pp. 131-139 (online: 07 February 2018)

Research Articles

Physical and mechanical characteristics of poor-quality wood after heat treatment

vol. 8, pp. 884-891 (online: 22 May 2015)

Research Articles

Heat treatment of poplar plywood: modifications in physical, mechanical and durability properties

vol. 16, pp. 1-9 (online: 09 January 2023)

Research Articles

Improving dimensional stability of Populus cathayana wood by suberin monomers with heat treatment

vol. 14, pp. 313-319 (online: 01 July 2021)

Short Communications

Changes in Populus sp. wood subjected to heat treatment: anatomy and silica content

vol. 18, pp. 223-226 (online: 09 August 2025)

Research Articles

Reversible and irreversible effects of mild thermal treatment on the properties of wood used for making musical instruments: comparing mulberry to spruce

vol. 15, pp. 256-264 (online: 20 July 2022)

Research Articles

Physical-mechanical properties and bonding quality of heat treated poplar (I-214 clone) and ceiba plywood

vol. 8, pp. 687-692 (online: 17 December 2014)

Research Articles

Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal

vol. 10, pp. 669-679 (online: 11 July 2017)

iForest Database Search

Search By Author

Search By Keyword

Google Scholar Search

Citing Articles

Search By Author

Search By Keywords

PubMed Search

Search By Author

Search By Keyword