Hardness and contact angle of thermo-treated poplar plywood for bio-building

iForest - Biogeosciences and Forestry, Volume 14, Issue 3, Pages 274-277 (2021)

doi: https://doi.org/10.3832/ifor3662-014

Published: May 29, 2021 - Copyright © 2021 SISEF

Research Articles

Collection/Special Issue: Research Project PRIN-MIUR 2015

The forest-wood value chain: biomass supply, traceability, C-footprint. Innovation for bioarchitecture and energy efficiency

Guest Editors: Scarascia Mugnozza G, Maesano M, Romagnoli M

Abstract

The interest towards poplar cultivation and its wood has recently been growing in Italy, where the use of timber and wood-based materials in construction is increasing as well. Poplar plywood, with a national production of around 270.000 m3 in 2017, is a key product for the Italian wood sector, and currently is destined for several applications as component for furniture and motorhomes. Previous research has shown that thermal treatment can be effectively applied to poplar plywood in order to make it suitable to the requirements of new end-uses. The present study aims to widen the knowledge of the effects of thermal treatment on poplar plywood. With this purpose, 7-layered, 12-mm thick plywood bonded with urea-melamine-formaldehyde (UMF) resin was thermally treated for 2 h at 170, 190 and 210 °C through the Termovuoto® process. The treatment aimed to improve the dimensional stability and durability against fungal decay. The process was set at lower temperature and shorter time than those of many thermal treatments commonly used in practice in order to limit the reduction in mechanical properties and to maintain an adequate bonding quality. The above properties were already verified by previous research, whereas in this study Brinell hardness and contact angle of treated panels were investigated as relevant for several end-uses that can be prospected in building and in outdoor environments. Brinell hardness decreased from 10.8 to 8.3 N mm-2 and contact angle increased from 75.8° to 103.6°. Overall, treatment at 190 °C seems the most suitable to induce balanced modifications in the panels. From a technical point of view, these appear ready to enter the market, for instance for use in exterior claddings, partitions and outdoor flooring.

Keywords

Brinell Hardness, Contact Angle, Plywood, Poplar, Thermo-treatment

Introduction

The interest towards the use of wood in construction has been growing steadily in the last two decades. This can be attributed mainly to the development of innovative wood-based and engineered products that have considerably widened the range of architectural timber solutions ([22]). Moreover, the environmental value of wood materials, in terms of low greenhouse gas emissions associated to their production, carbon dioxide storage, easiness of reuse etc., is ideal to meet the sustainability requirements set by the modern bio-building ([3], [25]).

The Italian construction sector is in line with this global interest towards wood and derived products. According to FederlegnoArredo ([18]), Italy was the fourth European producer of prefabricated timber buildings in 2018; 3144 buildings were constructed on the national territory with a turnover of 724 million euros, which represents a 5% increase compared to 2017. New timber buildings were mainly residential (91%, that is 7% of new dwellings), whereas non-residential buildings constituted the remaining minor share (9%).

The poplar supply chain is a key factor for the Italian wood sector given the annual volume of timber that was estimated 2.25 million m3 in 2014 ([17]). After decades characterized by a constant decrease in plantation coverage and operators ([2]), a renewed interest in poplar cultivation and its wood has re-emerged recently: the amount of plantations has been growing since 2015, reaching 46.125 ha in 2017 ([8]). This tendency is also due to the increased support from the Regions and the central government, as shown by several activities: the constitution of the National Poplar Observatory; the signature of the “Agreement for the development of the poplar supply chain” among Northern Regions where plantations are more diffuse; the compilation of an inventory of the Italian poplar cultivation (Monipoplar project); the publication of the “Guidelines for a sustainable poplar cultivation” ([8]).

Poplar wood is a versatile raw material that has many applications ranging from energy to construction. The national poplar cultivation sector is mainly geared towards producing assortments suitable for plywood manufacturing, which represents the higher valorization of poplar wood and timber. In 2017, the Italian production of poplar plywood reached about 270.000 m3 ([15]). Currently, this product is mainly destined to furniture, but a sizable proportion is also used in packaging, transport, do-it-yourself and construction.

Thermal treatment is widespread at the global level as an effective process to increase the dimensional stability and decay durability of wood ([16], [4]). Generally, the treatment is made on solid wood (sawn timber, sliced or rotary cut veneers). Four industries are active in Italy in the field of thermal modification technologies and several plants have been established at the national level ([20]). In recent years various studies have investigated the effects of thermal treatment on the properties of poplar wood and derived products, taking into account solid wood ([23]), veneers ([5], [27]), oriented strand board ([6]) and plywood ([19], [26]). In particular, Zanuttini et al. ([32]) investigated the effect of thermal treatment on poplar plywood by characterizing its density, bending strength, modulus of elasticity, bonding quality, color change and decay durability. Thermal treatment can broaden the applications of this panel, in particular with regard to non-structural uses in exterior environments under cover or exposed to the weather with limited wetting conditions (use classes UC 2 and UC 3.1, according to [11]). Poplar wood on its own, in fact, is not suited for applications in these exposures due to its low durability (class “DC 5 - not durable”, according to [12]).

The present study aims at widening the knowledge of the effects of thermal treatment on poplar plywood. To this purpose, poplar plywood was treated in a range of 170 to 210 °C for 2 h. In this work, temperatures were selected in the low-mid range of those commonly used, but different process parameters can be worth studying as well. The treatment aimed to improve the dimensional stability and decay durability of the panels while limiting the reduction in their mechanical properties and maintaining adequate color and bonding quality, which was already verified by Zanuttini et al. ([32]). In this study, Brinell hardness and contact angle of thermo-treated poplar plywood have been investigated as relevant properties for assessing its use in different applications in building.

Materials and methods

A detailed description of the poplar plywood subjected to testing and of the thermal treatment applied is reported in Zanuttini et al. ([32]). In brief, the experimental activity was performed on 7-layered, 12 mm thick poplar (I-214 clone) plywood with dimensions 2500×1200 mm produced at industrial scale in a plywood mill located in northwest Italy. Panels were bonded using a commercial urea-melamine-formaldehyde (UMF) resin suited for meeting the requirements of Class 2 according to the specifications of the EN-636:2012+A1 ([13]). Plywood was thermo-treated for 2 h at 170 °C (T1), 190 °C (T2) and 210 °C (T3) by means of the Termovuoto® process ([1]). Treating the entire plywood was preferred to treating veneers prior to composition because thermo-treated veneers are more brittle and their reduced hygroscopicity can hinder the subsequent bonding phase. Panels average density and mass losses (ML) due to thermal treatment correspond to those already reported in Zanuttini et al. ([32]): T0: 388 kg m-3; T1: 381 kg m-3, ML= 1.8%; T2: 358 kg m-3, ML=7.7%; T3: 353 kg m-3, ML=9.0%.

Overall, twelve panels were randomly sampled from the same batch of 150 panels. Nine of these were thermo-treated (three panels × three temperature treatments), whereas three untreated panels (T0) were used as control. Specimens were cut and conditioned at 20 °C and 65% relative humidity until the equilibrium moisture content was reached.

Brinell hardness (HB) was determined on 10 randomly cut specimens (50 × 50 × 12 mm) per panel type according to EN-1534 ([14]). One kN load was applied for 25 ± 5 s on each specimen through a steel ball indenter with diameter 10 ± 0.01 mm, and Brinell hardness was calculated as follows (eqn. 1):

where HB is the hardness (in N mm-2), F is the maximum load applied (in N), D is the diameter of the ball (in mm) d is the diameter of the residual indentation (in mm).

Diameters of residual indentation were measured using a stereo microscope Leica M205 C (resolution 1050 lp mm-1, which being apt to structures down to 476 nm is suitable to measure HB indentation according to eqn. 1) and the software Leica Application Suite (Leica AG, Wetzlar, Germany).

Contact angle was determined on 40 randomly cut specimens (50 × 50 × 12 mm) per panel type by means of the static sessile drop method using droplets of distilled water with volume 10 μl. Images were collected after 2 s from droplets released using a stereo microscope equipped with a camera. Images were processed through the software Photoshop® Elements ver. 11 (Adobe Inc., San José, CA, USA). The contact angle was measured using the plugin “Contact angle” developed by M. Brugnara for the software ImageJ (National Institutes of Health, USA - [31]).

The statistical analysis was performed using the software package SPSS® ver. 25.0 (IBM Corp., Armonk, NY, USA). Differences in contact angle between untreated and thermo-treated plywood were investigated through the Kruskal-Wallis non-parametric test, with the Dunn-Bonferroni test as a post-hoc. Differences in Brinell hardness were investigated by one-way analysis of variance (ANOVA) and LSD test as a post-hoc. Homogeneity of variance was verified by Levene’s test; significance was always set at a level of 0.05.

Results and discussion

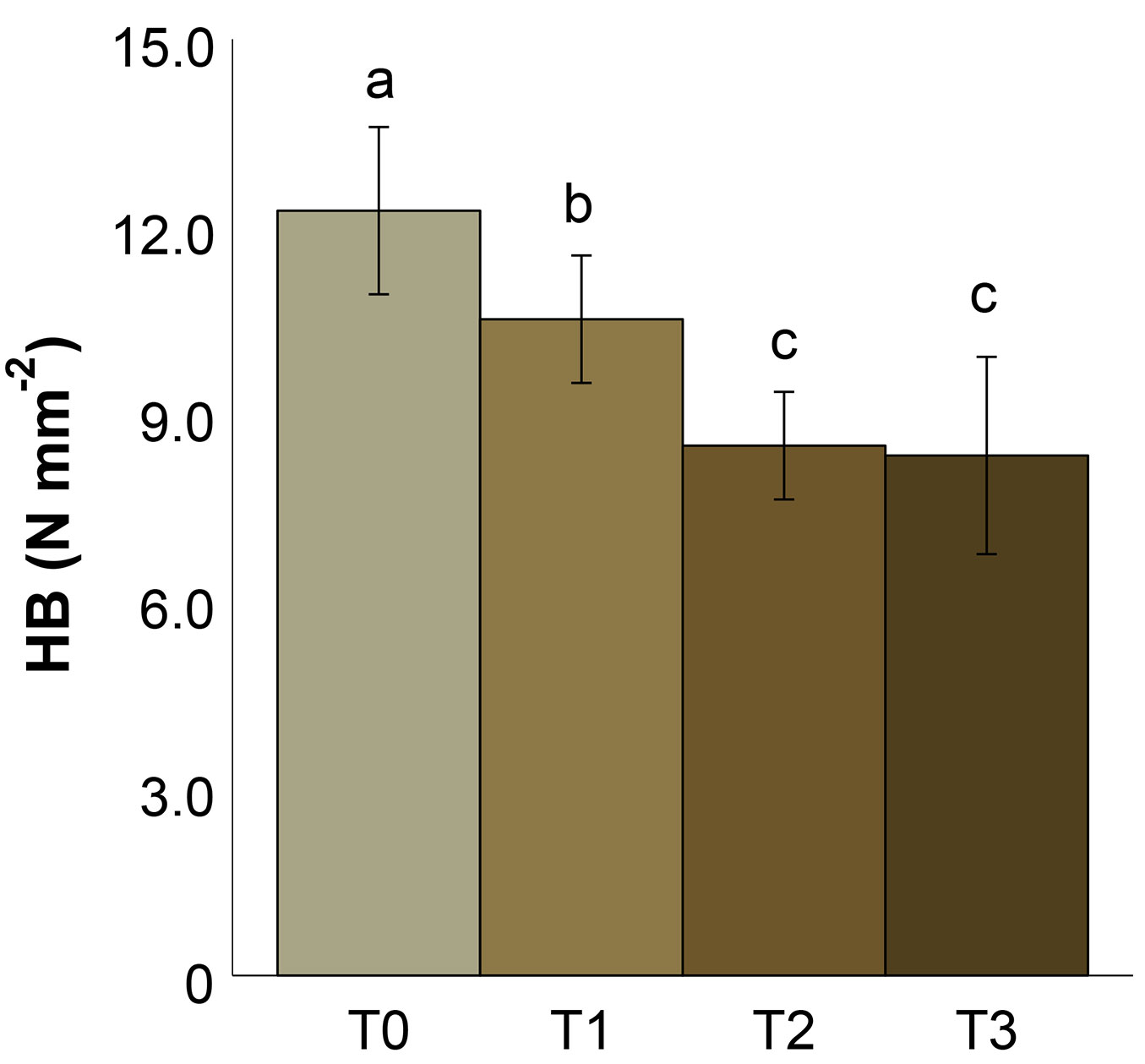

Brinell hardness of untreated and thermo-treated poplar plywood is illustrated in Fig. 1. Three groups were identified through LSD post-hoc test: T0, T1, and T2-T3 (p=0.776), with differences between groups always significant (p<0.005). Compared to T0, HB decreased as follows: T1= -12.2%, T2=-30.9%, T3=-32.5%. As for other mechanical properties, the reduction in HB can be related to the mass loss due to thermal treatment, as already reported in studies on poplar wood and other hardwoods ([28]). Decrease in HB can also be related to the reduction in modulus of elasticity that is typically induced by thermal treatment. In Brinell Hardness test, in fact, once the load is released wood springs back to some extent due to partial elastic recovery ([29]). Lower modulus of elasticity attenuates this effect, resulting in wider indentation and consequently in lower HB values (eqn. 1).

Fig. 1 - Average Brinell hardness (HB) of untreated and thermo-treated poplar plywood. Different letters indicate significant differences (p<0.05) among group means after Dunn-Bonferroni post-hoc test. The error bars represent the standard deviation.

Non-significant differences between T2 and T3 can be explained by the limited difference in mass loss due to thermal treatment (T2: 7.7%, T3: 9.0% - see above). In addition, non-significant differences could also be due to local collapses determined by the increasing brittleness of wood that could have affected the extension of the indentation area. Overall, considering that poplar wood is among the woods with lower hardness ([7]), the reduction in HB due to thermal treatment can constitute a critical aspect for some end applications.

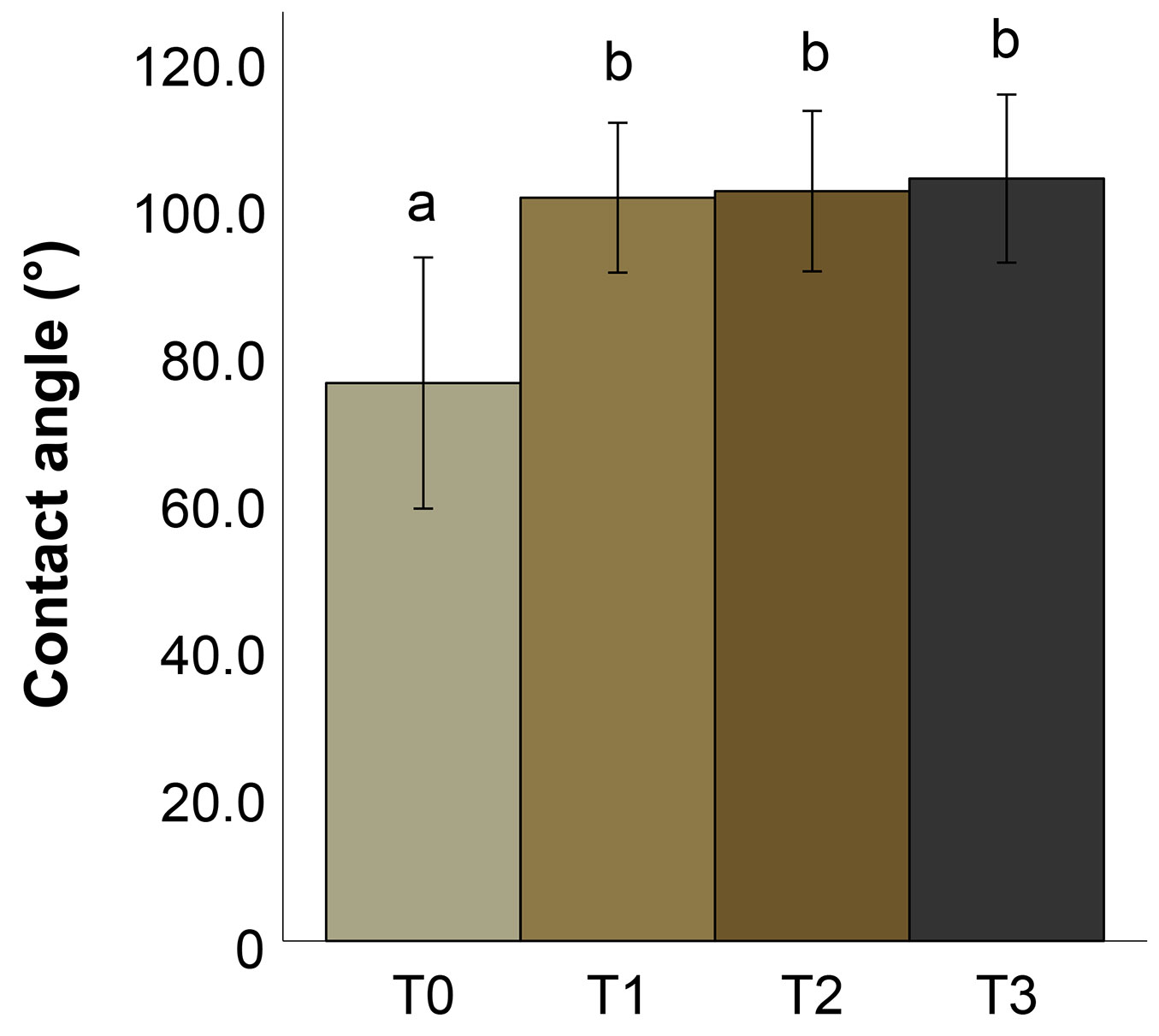

Fig. 2shows the measured values of contact angle. Two groups were identified through the Dunn-Bonferroni post-hoc test: T0 and T1-T2-T3. Differences between groups were always significant (p<0.001), whereas differences among T1, T2 and T3 resulted always not significant (p>0.700). Compared to T0, the contact angle of T1-T2-T3 was about 34% higher. This result is also attributable to the degradation of hemicelluloses and lignocellulosic components of wood, which is known to be the main cause of the increased hydrophobicity of thermo-treated wood ([24]). Results are consistent with those obtained by Hakkou et al. ([21]), who found that contact angle increased and remained constant for thermal modifications performed at temperatures higher than 120 °C. The non-significant differences among T1, T2 and T3 could also be explained by the close difference in intensity of the treatments performed (temperature increased by steps of 20 °C) that induced similar modifications in the chemical composition of the surface of thermo-treated plywood. This interpretation is in line with the results of a previous study by Unsal et al. ([30]). In this study, non-significant differences were found in contact angle of eucalyptus wood treated at 150 °C and 180 °C, indicating that 30 °C difference in treatment temperature does not necessarily affect the contact angle value. In addition, other studies have found that mass loss and reduction in wettability are not correlated ([16]).

Fig. 2 - Average contact angle of untreated and thermo-treated poplar plywood. Different letters indicate significant differences (p<0.05) among group means after Dunn-Bonferroni post-hoc test. The error bars represent the standard deviation.

Finally, Tab. 1provides an overview on the physico-mechanical properties of poplar plywood treated at 190 °C for 2 h (T2) through the Termovuoto® process.

Tab. 1 - Physico-mechanical properties of poplar plywood thermo-treated at 190 °C for 2 h through the Termovuoto® process. (a): values of Brinell hardness and contact angle derive from the present study; (b): values of density, bending strength (MoR), Modulus of Elasticity (MoE), bonding quality and decay durability are taken from Zanuttini et al. ([32]).

| Properties | Reference standard |

Unit | Mean ± st.dev |

|---|---|---|---|

| Brinell hardness a | EN-1534 | N mm-2 | 8.5 ± 0.9 |

| Contact angle a | - | degrees | 101.9 ± 10.9 |

| Density b | EN-323 | kg m-3 | 358 ± 7.1 |

| MoR b longitudinal | EN-310 | N mm-2 | 27.7 ± 3.0 |

| MoR b transversal | EN-310 | N mm-2 | 29.8 ± 4.7 |

| MoE b longitudinal | EN-310 | N mm-2 | 3840 ± 190 |

| MoE b transversal | EN-310 | N mm-2 | 3350 ± 100 |

| Bonding quality - Shear strength b | EN-314, Class 2 | N mm-2 | 1.07 ± 0.3 |

| Bonding quality - Fiber release b | EN-314, Class 2 | % | 76 ± 30 |

| Decay durability b - C. puteana | EN-12038 | Clx. | 1 |

| Decay durability b - G. trabeum | EN-12038 | Clx. | 1 |

| Decay durability b - T. versicolor | EN-12038 | Clx. | 4 |

| Decay durability b - P. ostreatus | EN-12038 | Clx. | 4 |

Conclusion

The need for sustainable construction constitutes a major opportunity for wood-based products. Thermal treatment can open new applications to poplar plywood, making it suitable for use in covered exterior or exterior environments where adequate decay durability is required. This is also interesting for promoting local supply chains and avoiding the use of chemical preservatives with higher environmental impact.

Basing on previous research carried out by the authors, in this study the treatment intensity was chosen in order to obtain a final product with balanced modifications. Reduction in Brinell Hardness ranged from about 12% to 30%, and contact angle increased of about 34%.

The results of this study widen the knowledge of the properties of thermo-treated poplar plywood. Overall, from a technical point of view and considering that it meets the requirements of bonding quality of the reference standard, the product appears ready to enter the market, with particular regard to plywood treated at 190 °C. This, considering the value added of thermal treated poplar plywood, could also contribute to sustaining the recent renewed interest towards poplar cultivation in Italy.

Acknowledgements

Part of the experimental activity was performed in collaboration with Dr. Gaetano Castro, CREA-Research Centre for Forestry and Wood.

References

Gscholar

Online | Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Authors’ Info

Authors’ Affiliation

Francesco Negro

Corrado Cremonini https://orcid.org/0000-0001-7569-9141

DISAFA, University of Torino, l.go Paolo Braccini 2, I-10095 Grugliasco, TO (Italy)

Corresponding author

Paper Info

Citation

Zanuttini R, Negro F, Cremonini C (2021). Hardness and contact angle of thermo-treated poplar plywood for bio-building. iForest 14: 274-277. - doi: 10.3832/ifor3662-014

Academic Editor

Giacomo Goli

Paper history

Received: Sep 29, 2020

Accepted: Apr 08, 2021

First online: May 29, 2021

Publication Date: Jun 30, 2021

Publication Time: 1.70 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2021

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 35971

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 30187

Abstract Page Views: 2758

PDF Downloads: 2409

Citation/Reference Downloads: 0

XML Downloads: 617

Web Metrics

Days since publication: 1717

Overall contacts: 35971

Avg. contacts per week: 146.65

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

Total number of cites (since 2021): 3

Average cites per year: 0.60

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Research Articles

Heat treatment of poplar plywood: modifications in physical, mechanical and durability properties

vol. 16, pp. 1-9 (online: 09 January 2023)

Research Articles

Physical-mechanical properties and bonding quality of heat treated poplar (I-214 clone) and ceiba plywood

vol. 8, pp. 687-692 (online: 17 December 2014)

Short Communications

Influence of thermo-vacuum treatment on bending properties of poplar rotary-cut veneer

vol. 10, pp. 161-163 (online: 13 June 2016)

Short Communications

Changes in Populus sp. wood subjected to heat treatment: anatomy and silica content

vol. 18, pp. 223-226 (online: 09 August 2025)

Research Articles

Pre-treatment with sodium silicate, sodium hydroxide, ionic liquids or methacrylate resin to reduce the set-recovery and increase the hardness of surface-densified Scots pine

vol. 10, pp. 857-864 (online: 26 October 2017)

Technical Advances

Technical properties of beech wood from aged coppices in central Italy

vol. 8, pp. 82-88 (online: 04 June 2014)

Research Articles

Thermo-modified native black poplar (Populus nigra L.) wood as an insulation material

vol. 14, pp. 268-273 (online: 29 May 2021)

Research Articles

Compositions of compounds extracted from thermo-treated wood using solvents of different polarities

vol. 10, pp. 824-828 (online: 25 September 2017)

Research Articles

Improving dimensional stability of Populus cathayana wood by suberin monomers with heat treatment

vol. 14, pp. 313-319 (online: 01 July 2021)

Research Articles

Kinetic analysis of poplar wood properties by thermal modification in conventional oven

vol. 11, pp. 131-139 (online: 07 February 2018)

iForest Database Search

Search By Author

Search By Keyword

Google Scholar Search

Citing Articles

Search By Author

Search By Keywords

PubMed Search

Search By Author

Search By Keyword