Changes in Populus sp. wood subjected to heat treatment: anatomy and silica content

iForest - Biogeosciences and Forestry, Volume 18, Issue 4, Pages 223-226 (2025)

doi: https://doi.org/10.3832/ifor4549-018

Published: Aug 09, 2025 - Copyright © 2025 SISEF

Short Communications

Abstract

Heat treatment of wood is a widely used process in the timber industry, particularly in European countries, involving controlled high temperatures to improve the physical and chemical properties of wood. This study analyzes the effects of heat treatment on the anatomy (fiber lumen and vessel diameter) and silica content of Populus deltoides wood (“Stoneville 67”), cultivated in Junín, Buenos Aires, Argentina. Scanning electron microscopy (SEM) microphotographs reveal an increase in fiber collapse with rising temperature (from 80 to 200 °C) and exposure time (from 60 to 120 minutes). Treatment at 200 °C for 60 minutes shows a notable increase in silica content (from 0.3% to 0.53%), which may positively influence the surface hardness of poplar wood, resulting in an improvement in this property.

Keywords

Introduction

Heat treatment of wood plays a fundamental role in the timber industry, subjecting wood to controlled high temperatures to enhance its physical and chemical properties ([5], [10], [9], [1], [4]). This method offers a sustainable alternative to traditional chemical preservation treatments (creosote, chromated copper arsenate), minimizing environmental contamination compared to natural wood ([11], [1]).

The process influences various properties, including dimensional stability, moisture resistance, insect and microorganism resistance, hardness, wear resistance, color, and appearance, among others ([17], [14], [18], [22]). Heat treatment induces chemical changes, such as the degradation of hemicellulose ([6]), reducing water absorption and release, thereby enhancing dimensional stability. Most reports on hygroscopicity ([10], [15], [9], [1]) observe a decrease in their values following heat treatment. However, some studies have reported contradictory behavior for this parameter ([16]).

Another essential component, lignin, undergoes fragmentation due to high temperatures, decreasing density and stiffness while increasing flexibility and reducing wood deformation ([15], [6]). Moreover, cellulose crystallization during heat treatment may enhance dimensional stability ([25], [21]). Additionally, silica, a mineral present in particular wood species, may experience significant changes during heat treatment, affecting properties such as hardness and durability ([20]).

From an anatomical perspective, as hemicellulose degrades and lignin alters, the cellular structure of the wood becomes denser, improving resistance to water and microorganisms ([6]). Heat treatment influences the size and shape of wood cells, affecting their mechanical and physical properties ([7], [3], [15]).

Despite its industrial application in several countries, heat treatment is not widely utilized in Latin American countries, such as Argentina ([16]). This study focuses on the effects of heat treatment on commercial woods in Argentina (Populus sp.), utilizing reference conditions from Spavento ([22]), who studied the same species in similar conditions.

The objective of this study was to analyze the influence of heat treatment on cellular structure (fiber lumen and vessel diameter) and silica content (percentage and influence on surface hardness) in Populus deltoides wood, aiming to identify temperatures and exposure times that lead to technological improvements in this wood.

Materials and methods

Random trees were selected from a commercial plantation of Populus deltoides “Stoneville 67” in Buenos Aires, Argentina. Five specimens, aged between 20 and 24 years, were chosen for sampling. The first two commercial logs (up to 6 meters in height) were used for thermal treatment and subsequent analysis using scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDX). The surface hardness data used to analyze whether silica content influences this parameter were presented in a previous study ([2]).

Two temperatures (80 and 200 °C) and two exposure times (60 and 120 minutes) were employed for the heat treatments, based on previous studies ([22] - Tab. 1). The heat treatment was conducted in an electric oven (ORL Company, Model SD755, 175-liter capacity) equipped with a high-precision Programmable Logic Controller (PLC - O.R.L.). After preheating to 80 °C, the samples were placed inside, and the timing commenced. After 60 minutes (T1), the first samples were removed, and the remainder continued for an additional 120 minutes (T2). The same procedure was followed for 200 °C.

Tab. 1 - Temperature and duration of exposure in heat treatments.

| Treatment | Temperature (°C) | Time (Minutes) |

|---|---|---|

| T1 | 80 | 60 |

| T2 | 80 | 120 |

| T3 | 200 | 60 |

| T4 | 200 | 120 |

| Untreated | - | - |

The ultra-structural anatomical analysis involved ten samples per treatment, including an untreated control sample, with dimensions of 2 × 2 × 2 cm. These samples were evaluated by the Non-Destructive Testing, Material and Product Evaluation Department of the National Institute of Industrial Technology (INTI, San Martín, Buenos Aires). Photomicrographs were obtained at various magnifications (100×, 1000×, 1500×) using a scanning electron microscope (SEM, high vacuum), enabling observation of the cellular structure in treated and untreated wood. Fiber lumen and vessel diameter were measured, with 500 measurements per treatment and untreated wood, using ImageJ software v. 1.52a.

The chemical analysis involved observing the samples under the scanning electron microscope coupled with energy dispersive X-ray spectroscopy (EDX) using a Philips 505® SEM to determine the elemental composition of treated and untreated wood.

The values for fiber lumen, vessel diameter, and silica content were statistically analyzed with respect to the applied heat treatments. The relationship between silica content and previously reported surface hardness values was also examined.

Results and discussion

Anatomical changes in response to thermal treatment

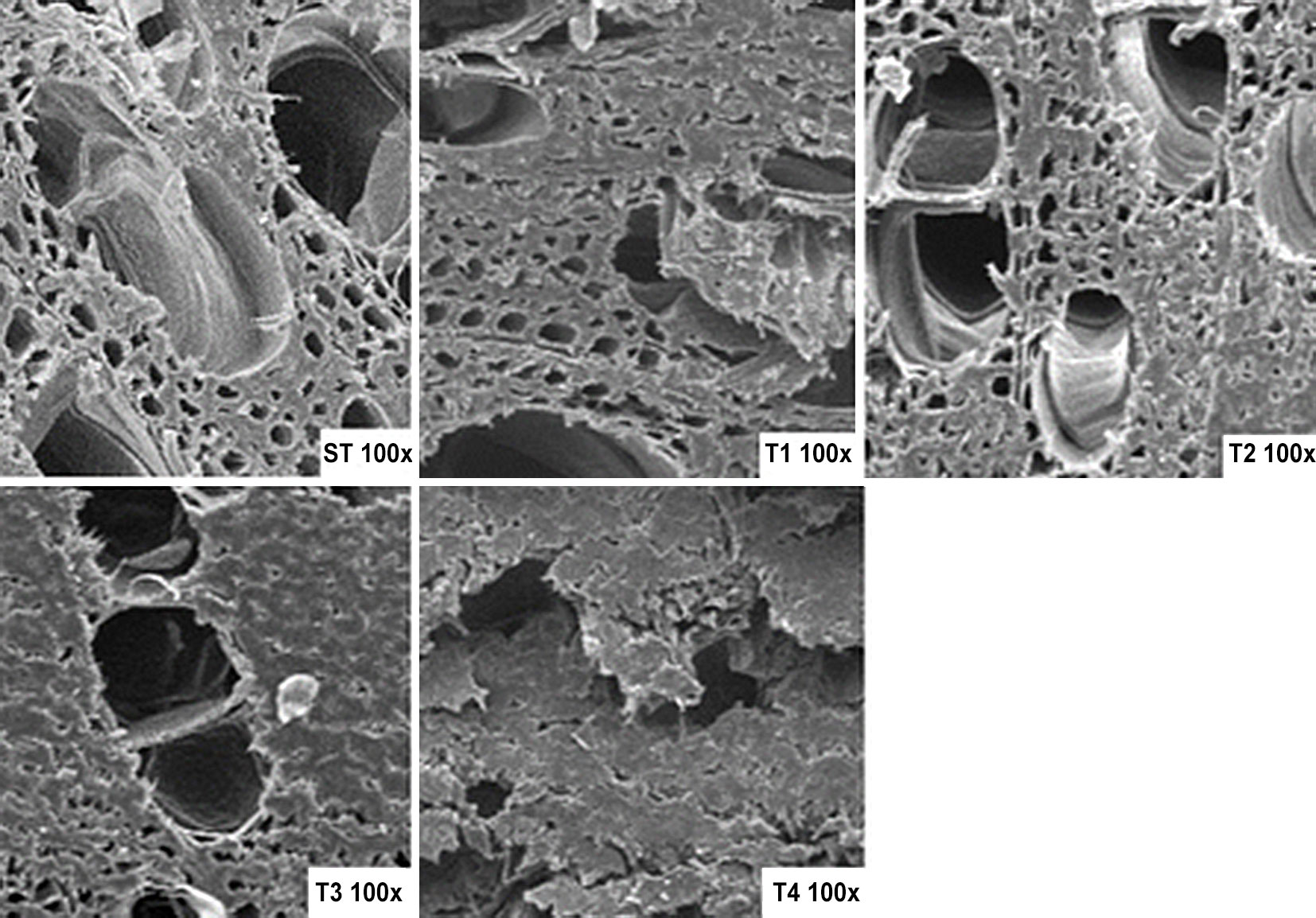

As temperature and exposure time increase during the heat treatment process (from T1 to T4 in ascending order of intensity and exposure time), the collapse of wood fibers becomes more pronounced (Fig. 1). Specifically, Treatment 4 exhibits a notable collapse of the cell walls upon sectioning, which is more pronounced than in the other treatments. These findings align with the conclusions of Boonstra et al. ([3]) regarding the effects of heat treatment on softwoods, where it was reported that poplar wood is particularly susceptible to the collapse of its cellular structures when exposed to high temperatures. A similar result was reported by Päivi ([18]) concerning thermally treated pine wood.

Fig. 1 - Photomicrographs of Treated (T1, T2, T3, and T4) and Untreated (U) poplar wood taken at 100× magnification. See Tab. 1 for the details of each treatment.

Based on the measurements of fiber lumen and vessel diameter (Tab. 2), it can be inferred that heat treatments significantly affect the collapse resistance of fibers and vessels. As both temperature and exposure time increase, both parameters decrease. The analysis of variance revealed significant differences (p < 0.005) among the treatments. According to the Tukey test, the most notable differences were observed between untreated wood and Treatment T3 for fiber lumen (15.15 vs. 5.09 mm) and between the control wood and Treatment T4 for vessel diameter (118 vs. 82 µm).

Tab. 2 - Fiber lumen and vessel diameter in poplar wood. Lowercase letters are to be read vertically within each parameter. Different letters indicate significant (p<0.05) differences in those characteristics between the applied treatments, according to Tukey’s test. Fiber lumens under Treatment T4 could not be measured due to fiber collapse.

| Treatment | Fiber lumen avg. (µm) |

Vessel diameter avg. (µm) |

|---|---|---|

| U | 15.15 c | 118.85 c |

| T1 | 11.05 b | 111.69 cb |

| T2 | 8.81 b | 82.21 ab |

| T3 | 5.09 a | 87.47 ab |

| T4 | - | 56.46 a |

Silica percentage

The results of this study indicate that the silica content in untreated poplar wood (0.30% Si) falls within previously established parameters ([8], [12]). However, after heat treatment, an increase in the silica percentage was observed (T1: 0.34%, T2: 0.32%, T3: 0.53%, T4: 0.35%), particularly notable in Treatment T3 (200 °C / 60 minutes). The significant increase in silica content in Treatment T3 can be attributed to the interaction between exposure time and temperature, which likely triggered a more extensive decomposition of silicates, resulting in a more substantial release of silica compared to other treatments ([13], [19]). However, Treatment T4 showed a decrease in silica percentage (0.32%), indicating that the exposure time may negatively impact the degradation of silicate compounds, thus affecting its final value. Despite a slight upward trend in all treatments, the only significant difference in silica content was found between Treatment T3 and the others (ANOVA p < 0.005, Tukey tests, α = 0.05). When incorporated into the cellular structure, silica may contribute to increased wear resistance and surface penetration ([20]). This is consistent with previous findings by Ziliani ([26]) regarding the hardening of wood due to the presence of silica. Given this context, the relationship between surface hardness values reported by Aragón ([2]) for this same material and the silica percentage values presented in this study was analyzed. It was observed that with T3 at 0.53% silica, the surface hardness value was higher (372 kg cm-2) than that of the control wood (283 kg cm-2), indicating that the silicate compounds produced at that temperature and exposure time enhance surface wear resistance. This increase in surface hardness in heat-treated poplar wood has been previously reported by Taraborelli et al. ([24]), emphasizing the importance of exposure time and temperature. According to our results, at 200 °C and 60 minutes (T3), Populus deltoides €˜Stoneville 67’ shifts from being classified as very soft (untreated) to soft (heat treated), according to the classification by García & García (values extracted from [23]).

Conclusion

The results indicate that the effects of heat treatment on poplar wood are directly related to the temperature and exposure time employed. The lowest values of fiber lumen and silica percentage were observed in Treatment 4 (200 °C and 120 minutes), while the lowest vessel diameter was obtained in Treatment 3 (200 °C and 60 minutes).

The relationship between silica percentage and the increase in surface hardness highlights the importance of understanding these processes to optimize the properties of treated wood. Modifying this parameter would allow Populus deltoides“Stoneville 67” to be classified from very soft (untreated) to soft (thermally treated), according to the classification by García & García (values extracted from [23]).

Future research in this field should investigate how these enhancements in properties can translate into specific practical applications. This would open new avenues for advancing thermal wood treatment technology in Argentina, contributing to the sustainable and efficient development of the wood industry.

References

Online | Gscholar

Gscholar

Gscholar

Online | Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Authors’ Info

Authors’ Affiliation

Miguel Antonio Tortoriello 0000-0001-7468-639x

Patricio Germán Arrien 0009-0009-3332-1760

Laboratorio de Ensayos de Materiales y Estructuras, Universidad Nacional del Noroeste de Buenos Aires, CIC, Sarmiento 1169, Junín, Bs. As. (Argentina)

Consejo Nacional de Investigaciones Científicas y Técnicas, Godoy Cruz 2290 (C1425FQB) CABA (Argentina)

Corresponding author

Paper Info

Citation

Cobas AC, Tortoriello MA, Arrien PG (2025). Changes in Populus sp. wood subjected to heat treatment: anatomy and silica content. iForest 18: 223-226. - doi: 10.3832/ifor4549-018

Academic Editor

Paola Cetera

Paper history

Received: Dec 26, 2023

Accepted: Mar 24, 2025

First online: Aug 09, 2025

Publication Date: Aug 31, 2025

Publication Time: 4.60 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2025

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 3427

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 1179

Abstract Page Views: 1044

PDF Downloads: 1111

Citation/Reference Downloads: 0

XML Downloads: 93

Web Metrics

Days since publication: 197

Overall contacts: 3427

Avg. contacts per week: 121.77

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

(No citations were found up to date. Please come back later)

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Short Communications

Effect of intensive planting density on tree growth, wood density and fiber properties of maple (Acer velutinum Boiss.)

vol. 9, pp. 325-329 (online: 22 October 2015)

Research Articles

Hardness and contact angle of thermo-treated poplar plywood for bio-building

vol. 14, pp. 274-277 (online: 29 May 2021)

Research Articles

Effect of silver nanoparticles on hardness in medium-density fiberboard (MDF)

vol. 8, pp. 677-680 (online: 17 December 2014)

Research Articles

Improving dimensional stability of Populus cathayana wood by suberin monomers with heat treatment

vol. 14, pp. 313-319 (online: 01 July 2021)

Research Articles

Impact of rotation length of Eucalyptus globulus Labill. on wood production, kraft pulping, and forest value

vol. 15, pp. 433-443 (online: 20 October 2022)

Review Papers

Wood anatomy of boreal species in a warming world: a review

vol. 13, pp. 130-138 (online: 09 April 2020)

Research Articles

Validation of models using near-infrared spectroscopy to estimate basic density and chemical composition of Eucalyptus wood

vol. 17, pp. 338-345 (online: 03 November 2024)

Technical Advances

Technical properties of beech wood from aged coppices in central Italy

vol. 8, pp. 82-88 (online: 04 June 2014)

Research Articles

Kinetic analysis of poplar wood properties by thermal modification in conventional oven

vol. 11, pp. 131-139 (online: 07 February 2018)

Research Articles

Thermo-modified native black poplar (Populus nigra L.) wood as an insulation material

vol. 14, pp. 268-273 (online: 29 May 2021)

iForest Database Search

Search By Author

Search By Keyword

Google Scholar Search

Citing Articles

Search By Author

Search By Keywords

PubMed Search

Search By Author

Search By Keyword