The effectiveness of short-term microwave irradiation on the process of seed extraction from Scots pine cones (Pinus sylvestris L.)

iForest - Biogeosciences and Forestry, Volume 13, Issue 1, Pages 73-79 (2020)

doi: https://doi.org/10.3832/ifor3089-012

Published: Feb 13, 2020 - Copyright © 2020 SISEF

Research Articles

Abstract

The influence of short-term microwave irradiation on the process of seed extraction from Scots pine cones was investigated in this study. Cones from the Brzesko Forest District (near Kraków, southern Poland) were collected in 2015. The size and changes in the mass of cones during the process of seed extraction, as well as the relations between these parameters, were analyzed. Changes in water content and drying rate of cones were modeled using suitable mathematical equations. The thermal balance of the whole process of seeds extraction was calculated, and the heat necessary to extract the seeds was determined. Cones were initially exposed to 2.45 GHz microwaves with a power of 800 W for either 5 or 15 seconds. Subsequently, cones were placed in a circulating air oven and seeds extracted under convective drying at a constant temperature of 50 ± 0.1 °C. We found that seeds from cones subjected to 15-seconds microwave radiation were dramatically damaged, while no significant difference were found in germination and quality of seeds between cones subjected to the 5-seconds microwave pre-treatment and control cones, both yielding first-class quality seeds (mean germination capacity > 90%). The results of this study could help developing microwave-dryer control algorithms to support the automated process of cone seed extraction in large-capacity extraction plants.

Keywords

Seed Extraction Heat, Drying Process, Moisture Content, Seed Viability

Introduction

The literature on seed extraction from conifer cones reports processes conducted under laboratory and/or industrial conditions, both in extraction chambers and cabinets. All stages of the process of production of forest reproductive material, from cones collection to nursery cultivation and selection, may have an effect on its genetic diversity - mainly by directional selection - that should be carefully considered ([15]). Most studies have sought to identify methods of convective cone drying characterized by short processing time and high viability of the resulting seeds ([7], [5], [23], [2]). To date, research was carried out on changes in moisture content of cones during seed extraction, the determinants of those changes, as well as moisture content upon seed release ([2]). Despite these efforts, the introduction of new methods for seed extraction has not led to shortening the process, nor to avoiding non-simultaneous opening of cones in the drying chamber. Furthermore, there is little evidence in the literature on the use of additional treatments, such as brief exposure of individual cones to microwaves. It is worth to remember that excessive microwave irradiation of biological material results in tissue and cell damage ([8], [18], [19], [20], [35], [16], [17], [27], [34], [11], [33]). The available evidences on intermittent microwave drying indicate that it affects the biophysical characteristics of various plants ([10]), including rice ([36]), amaranth ([13]), rapeseed ([21], [14], [31]), and tree seeds and seedlings ([26]), which lose vitality due to an abrupt microwave-induced temperature rise.

The effects of microwave irradiation on Pinus sylvestris cones were described by Aniszewska & Slowinski ([4]), who determined safe cone exposure time in terms of ensuring seed quality. Furthermore, Aniszewska ([3]) investigated surface temperature changes in cones exposed to microwaves for different periods. Finally, Hemis et al. ([12]), who analysed microwave-assisted drying of rapeseed, soy, and corn, reported that microwaves may cause seed cracking, which is deleterious to their quality.

The objective of the paper was to elucidate changes in the moisture content of pine cones briefly exposed to microwave irradiation prior to conventional seed extraction, taking into account the effects of cone size, initial moisture content, and drying temperature. Additional goals were to develop a mathematical model describing the drying process and assess the viability of the obtained seeds. The eventual increase of the effectiveness of the process of seed extraction from cones will support research efforts aimed at increasing the production of pine cones ([22]).

Materials and methods

Characteristics of the material

Scots pine (Pinus sylvestris L.) cones were collected in December 2015 from the So60 seed stand (53° 00′ N, 15° 00′ E) in the Brzesko Forest District (Kraków State Forests Regional Directorate). The cones were stored under refrigeration at 0 °C for 8 months. Following removal from refrigeration, the cones were acclimatized at room temperature (20-22 °C) for approximately 2 h at a relative air humidity of 40%.

Prior to seed extraction, the length (l) and the widest diameter (d) of each cone were measured. The diameter was determined in two orthogonal directions and the mean calculated. The measurements were made using a 0-150 mm digital hardened stainless steel caliper with an LCD display, with an accuracy of 0.1 mm.

Microwave irradiation and seed extraction

The pine cones were divided into three lots, each containing 40 specimens (a total of 120). The control lot (“lot C”) was subjected to conventional seed extraction, while the other two lots were initially exposed to 2.45 GHz microwaves with a power of 800 W in a Sharp R-200® laboratory microwave oven (Vestel Poland Sp. z o.o., Warsaw, Poland). The exposure time was either 5 seconds (“lot 5 s”) or 15 seconds (“lot 15 s”).

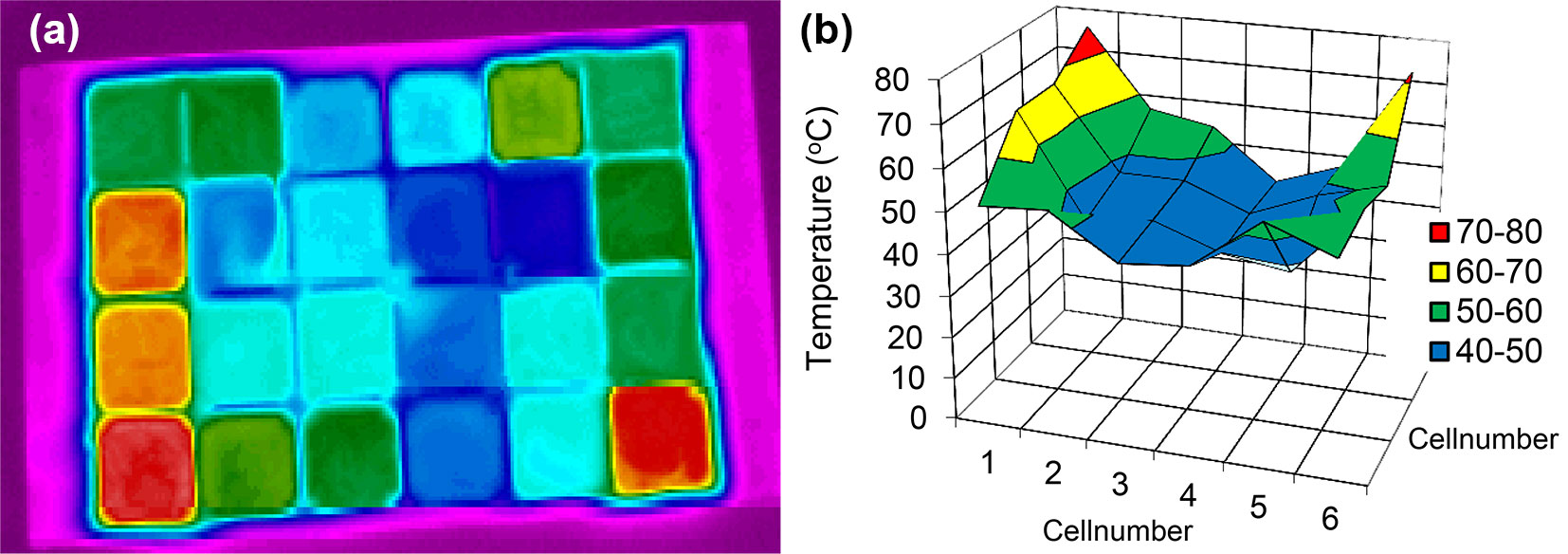

Temperature distribution within the microwave oven was determined in order to appropriately position the cones. A container measuring 12 × 8 cm divided into 24 cells (6 × 4) was placed in the oven, with 10 mL of demineralized water at 21 °C in each cell. The container with water was exposed to the maximum microwave power for 60 and 120 s, and then photographed with a VIGOcam V50® thermographic camera (VIGO System S.A., Ozarów Mazowiecki, Poland) from a distance of 50 cm. The adopted emissivity coefficient for water was 0.97. Images were acquired at a resolution of 384 × 288 pixels and processed using Therm v.2.29.3 software (VIGO System). Temperature was recorded with an accuracy of 0.1 °C. The obtained temperature distribution is shown in Fig. 1.

Fig. 1 - Temperature distribution in a container filled with water exposed to microwaves in the oven after 1 min. (a): thermograph; (b): 3D-graph.

After determining temperature distribution in the oven, cones were individually irradiated. Each cone was placed horizontally in the middle of a rotating glass plate. Before and 10 min after microwave treatment each cone was weighed on a WPS210 S® laboratory balance (Radwag, Radom, Poland) to record their initial (mp) and final (mk) weight with an accuracy of 0.001 g. It was experimentally determined that cone weight did not further change 10 min after the end of thermal treatment. Subsequently, the pine cones were placed in a Heraeus UT 6120® circulating air oven (Kendro Laboratory Products GmbH, Hanau, Germany) and subjected to seed extraction under convective drying at a constant temperature of 50 ± 0.1 °C and relative air humidity decreasing from 42% to 12%. The convective drying lasted 10 hours. Temperature and humidity in the oven and in the laboratory were monitored using an FTH 100® sensor (Geo FENNEL, Kassel, Germany) with an accuracy of 0.01 °C and 0.01%, respectively.

During seed extraction, cones were placed on the grill inside the oven. The decrease in weight was recorded every 60 ± 1 min over 10 h.

Seed extraction process and seed extraction heat

The study sought to describe the seed extraction process by mathematical equations, including the effects of initial microwave irradiation. Two equations were developed: one for the time interval of 0-0.16(6) h and another one for 0.16(6)-10 h. The former equation represents a linear function corresponding to the period required for the microwave treatment (5 s or 15 s) of individual cones comprising a given experimental lot, so that the entire lot could be then simultaneously placed in the convective (circulating air) oven. The latter equation is an exponential function corresponding to the time of seed extraction in the convective oven.

Given that the moisture content of the studied pine cones was much lower than that of so far researched plants or plant products, changes in cone moisture content (ui) during seed extraction in the convective oven were modeled using the exponential equation for the second period of drying solids given by Pabis ([25] - eqn. 1):

where uo is the initial cone moisture content, uk is the final cone moisture content, b is the characteristic drying coefficient, τ is the drying time, exp is the base of the natural logarithm. Moreover, instantaneous cone weight (mi) was measured during seed extraction to calculate instantaneous cone moisture content (uw) as the ratio of the weight of water (mH2O) to the dry weight of the cone (ms), which was also measured.

The coefficient b was determined for each cone on the basis of actual changes in moisture content (eqn. 2):

where n is the number of readings of cone weight mi and time τi during seed extraction. This coefficient was averaged and adopted as the characteristic parameter of the mathematical model describing moisture content changes in the cones, with the other characteristic parameters of the model being uo and uk.

The drying rate (loss of cone moisture over time) was calculated as the derivative of moisture content duration ui (eqn. 3):

The pine cones were weighed using a WPS210S® laboratory scale (Radwag, Radom, Poland) with an accuracy of 0.001 g. The dry weight of cones was determined after seed extraction by drying at 105 ± 1 °C until constant weight. After drying, the number of scales on the cone and the number of obtained seeds were counted. The seeds were cleaned and dewinged. The overall weight of seeds and wings from a given cone was measured with an accuracy of 0.001 g.

The heat of extraction Q for individual cones was calculated from the formula (eqn. 4):

where Q1 is the amount of heat supplied to the cone to reach the drying temperature (eqn. 5), and Q2 is the amount of heat needed to evaporate the water during seed extraction (eqn. 6):

Qs is the amount of heat needed to heat up the cone (J), Qw is the amount of heat needed to heat up water (J), cp is the heat of water evaporation equal to 2354.54 J g-1, cs is the specific heat of the cone, equal to 1.356 J (g °C)-1, cw is the specific heat of water equal to 4.18868 J (g °C)-1, mw is the weight of water (g), mwk is the weight of water remaining in the cone (g), Δt is the temperature difference (°C).

The amount of water that evaporated from the cone (mwe, g) and the amount of water remaining in the cone (mwf, g) were calculated as follows (eqn. 7, eqn. 8):

where mp is initial mass of the cone in grams, mk is the final weight of the cone in grams.

In calculating seed extraction heat, the heat needed to heat up the oven and air was not taken into account. Thus, Q is the effective seed extraction heat.

Germination energy and capacity

To determine whether the adopted seed extraction conditions result in viable seeds, their germination energy and capacity were assessed ([28], [37]). The pine seeds were placed on filter paper in a Jacobsen germinator (Laborset, Lódz, Poland) in three replicates of 100 specimens for each seed lot (5 s, 15 s, and C), totaling nine replicates (i.e., 900 specimens). The twenty-four hour operating cycle of the germinator consisted of 8 hours of lighting and 16 hours of dark. During the lighting period the seed temperature was kept at 30 °C, while during the remaining 16 hours it was equal to 20 °C. Temperature settings were regulated by the TERMO-STAB RBS1® controller (TERMO-STAB, Warsawa, Poland) with an accuracy of ± 1 °C. GRASSLIN Talento® 371 exposure time controller (Grässlin GmbH, St. Georgen, Germany) was used. The light source consisted of two fluorescent lamps TUNGSRAM 36W-F74 DAYLIGHT. Germination energy was measured after 14 days and germination capacity after 28 days of experiment. Based on those results, the seed quality class was determined according to the standard PN-R-65700 ([28]). First class pine seeds should germinate in 91% of the cases.

Statistical analysis

The external parameters of the cones were statistically evaluated using the software Statistica ver. 13 ([9]). The Shapiro-Wilk test was applied to evaluate normal distribution of the dependent variables. Differences in mean size and weight parameters were assessed by the ANOVA F-test and Duncan test for equal sample sizes. Homogeneity of variances were also tested using the Levene’s test. All analyses were made at a statistical significance level of 0.05.

Results

Characteristic parameters of Scots pine cones

Tab. 1 presents the basic size parameters (length, diameter, and length-to-diameter ratio) and initial weight for the three studied lots of pine cones. The mean length, diameter, and initial weight calculated for all cones were 45.77 mm, 21.50 mm, and 7.98 g, respectively, which is within the typical range for Scots pine ([6]). Cone size and weight showed a normal distribution after the Shapiro-Wilk test. Duncan test for equal sample sizes did not show any significant differences in length, diameter, or initial weight between the three studied lots of cones, which means that they may be compared each other.

Tab. 1 - Cone size and weight statistics for the three investigated lots. Two lots were initially exposed to 2.45 GHz microwaves, the exposure time was either 5 s (“lot 5 s”) or 15 s (“lot 15 s”). The control lot (“lot C”) was subjected only to conventional seed extraction. (l): length (mm); (d): diameter (mm); (l/d): length-to-diameter ratio; (mp): initial weight (g).

| Lot | Param | Mean | Min | Max | Range | Variance | SD | CV | SE |

|---|---|---|---|---|---|---|---|---|---|

| 5 s | l | 45.84 | 35.70 | 52.50 | 16.80 | 25.64 | 5.06 | 11.05 | 0.90 |

| d | 21.55 | 17.00 | 24.60 | 7.60 | 3.56 | 1.89 | 8.75 | 0.33 | |

| l/d | 2.13 | 1.69 | 2.55 | 0.86 | 0.04 | 0.19 | 8.98 | 0.03 | |

| m p | 7.96 | 4.79 | 11.32 | 6.53 | 3.36 | 1.83 | 23.01 | 0.32 | |

| 15 s | l | 45.83 | 37.80 | 56.80 | 19.00 | 18.66 | 4.32 | 9.43 | 0.76 |

| d | 21.28 | 18.40 | 25.00 | 6.60 | 3.29 | 1.81 | 8.52 | 0.32 | |

| l/d | 2.16 | 1.89 | 2.62 | 0.72 | 0.03 | 0.16 | 7.55 | 0.03 | |

| m p | 7.97 | 5.30 | 13.15 | 7.85 | 3.83 | 1.96 | 24.55 | 0.35 | |

| C | l | 45.24 | 37.60 | 56.10 | 18.50 | 19.92 | 4.46 | 9.87 | 0.80 |

| d | 21.67 | 17.80 | 26.10 | 8.30 | 4.12 | 2.03 | 9.36 | 0.36 | |

| l/d | 2.09 | 1.73 | 2.50 | 0.77 | 0.03 | 0.18 | 8.61 | 0.03 | |

| m p | 8.01 | 5.10 | 12.68 | 7.58 | 3.90 | 1.98 | 24.11 | 0.35 |

The mean length-to-diameter ratio was 2.13, which places the cones in the long-and-thick category (l/d = 0.20-0.25) according to Pravdin ([29]). In the studied material, there were also 16 egg-shaped cones (l/d = 1.50-2.00) and 2 long ones (l/d = 2.50-3.00).

A significant linear relationship (R=0.630) was found between cone diameter (d) and length (l - eqn. 9):

and between initial weight (mp) and length of cones (R = 0.554 - eqn. 10):

Thus, the longer the cone, the larger its diameter and initial weight. The mean initial moisture content of the cones (u0) amounted to 23 ± 1.5%.

The process of seed extraction

The total seed extraction time for Scots pine cones lasted 10 h, which was sufficient for all cones to open and release seeds. Moisture content for the studied lots is given in Tab. 2. Statistical analysis revealed that the mean moisture content values did not differ significantly between the three lots of cones, whereby the results can be deemed homogeneous. Throughout the 10 h long drying process, the cones initially exposed to microwaves for 5 s lost 1.13 g (from 0.670 g to 1.780 g), while those with a 15 s initial exposure lost 1.14 g (from 0.821 g to 1.839 g). A 5 s exposure to microwaves led to an average decrease in cone weight of 0.036 ± 0.014 g (from 0.010 g to 0.060 g), while a 15 s exposure led to a decrease of 0.447 ± 0.127 g (from 0.230 g to 0.841 g). Changes in moisture content calculated from weight loss indicate that microwave heating resulted in a moisture loss of 0.0055 (0.5%) and 0.069 (6.9%) kgH2O kgdw-1 for the 5s and 15 s lots, respectively.

Tab. 2 - Parameters of the mathematical equation describing seed extraction from Scots pine cones. (up): moisture content prior to microwave irradiation (kgH2O kgdw-1); (uo): moisture content after microwave irradiation (kgH2O kgdw-1); (uk): final moisture content after seed extraction (kgH2O kgdw-1); (b): coefficient (1 h-1) from eqn. 1 to 3 (see text). (SD): standard deviation; (CV): coefficient of variation; (SE): standard error of the mean.

| Lot | Param | Mean | Min | Max | Range | SD | CV | SE |

|---|---|---|---|---|---|---|---|---|

| 5 s | u p | 0.232 | 0.205 | 0.269 | 0.064 | 0.015 | 6.425 | 0.003 |

| u o | 0.227 | 0.199 | 0.263 | 0.064 | 0.015 | 6.575 | 0.003 | |

| u k | 0.057 | 0.029 | 0.087 | 0.058 | 0.009 | 16.285 | 0.002 | |

| b | 0.31 | 0.14 | 0.44 | 0.30 | 0.07 | 21.57 | 0.01 | |

| 15 s | u p | 0.227 | 0.189 | 0.264 | 0.075 | 0.015 | 6.688 | 0.003 |

| u o | 0.157 | 0.120 | 0.206 | 0.086 | 0.018 | 11.731 | 0.003 | |

| u k | 0.050 | 0.020 | 0.076 | 0.056 | 0.011 | 21.868 | 0.002 | |

| b | 0.39 | 0.29 | 0.47 | 0.18 | 0.04 | 11.14 | 0.01 | |

| C | up= uo | 0.233 | 0.205 | 0.267 | 0.062 | 0.013 | 5.587 | 0.002 |

| u k | 0.058 | 0.046 | 0.077 | 0.031 | 0.008 | 13.740 | 0.001 | |

| b | 0.32 | 0.21 | 0.40 | 0.24 | 0.07 | 21.97 | 0.01 |

In the case of control cones, moisture content up equaled uo as they were not pretreated with microwave irradiation prior to placement in the convective oven.

Moisture content uo, final moisture content uk, and b coefficients characteristic of the drying curve significantly differed between cones initially exposed to microwaves for 5 s and 15 s, while no significant differences were found between the 5 s lot and the control lot, as evaluated by the Duncan test (Tab. 3).

Tab. 3 - Results (p-values) of the Duncan test for differences in cone moisture content after microwave irradiation (uo), final moisture content (uk), and b coefficient for the three studied lots. (*): p<0.05; (ns): not significant.

| Lot | Param | 5 s | 15 s | C |

|---|---|---|---|---|

| 5 s | u o | - | 0.0001* | 0.1114ns |

| u k | - | 0.0043* | 0.4021ns | |

| b | - | 0.0001* | 0.6098ns | |

| 15 s | u o | 0.0001* | - | 0.0001* |

| u k | 0.0043* | - | 0.0300* | |

| b | 0.0001* | - | 0.0001* | |

| C | u o | 0.1114ns | 0.0001* | - |

| u k | 0.4021ns | 0.0300* | - | |

| b | 0.6098ns | 0.0001* | - |

After 10 h of seed extraction, the lowest final moisture content was found for the cones pretreated with microwaves for 15 s (0.050 kgH2O kgdw-1, or 5.0%). In turn, the lowest b coefficient was identified for the cones pretreated with microwaves for 15 s (0.31 1 h-1).

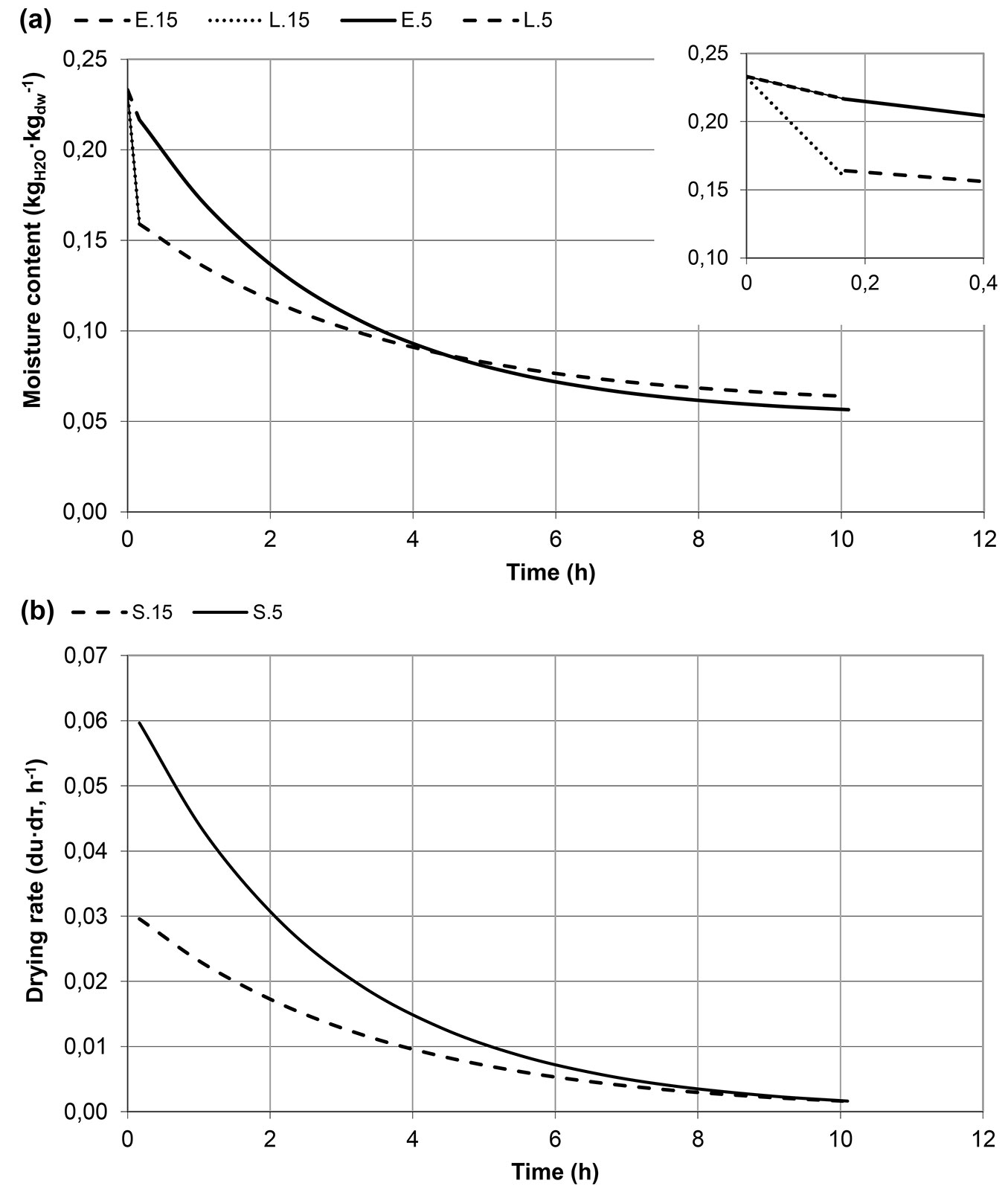

Fig. 2 - Changes in moisture content (a) and drying rates (b) for cones subjected to seed extraction with 5 s and 15 s microwave pretreatment. (a): Moisture content changes described by linear (L) and exponential (E) functions; (b): drying rate (S: seed extraction).

Fig. 2a presents the moisture content change in the course of seed extraction for two cones exposed to microwaves for 5 s or 15 s prior to extraction (curves E.5 and E.15, respectively). Mathematical equations describe those curves according to eqn. 1 and eqn. 3. The process of seed extraction following 5 s exposure to microwaves is given by eqn. 11, for uo= 0.217 kgH2O kgdw-1, uk = 0.052 kgH2O kgdw-1, and b = 0.36 1 h-1 (eqn. 11):

for τ∈(0.16(6) -10>.

The extraction process following 15 s exposure to microwaves is given by eqn. 12, for uo= 0.159 kgH2O kgdw-1, uk = 0.058 kgH2O kgdw-1, and b = 0.29 1 h-1 (eqn. 12):

for τ∈(0.16(6) -10>.

Fig. 2a also shows an initial loss of moisture caused by exposure to microwaves for 5 s and 15 s (functions L.5 and L.15, respectively). The pretreatment, which lasted for a total of 10 min, is described by linear eqn. 13 [τ∈<0-0.16(6) >]:

for 5s up = 0.233 kg H2O kgdw-1, and by eqn. 14 [τ∈<0-0.16(6) >]:

for 15s up = 0.232 kg H2O kgdw-1.

Fig. 2b shows drying rate curves for the studied cones, expressed by eqn. 15 for the 5 s lot [τ∈<0-0.16(6) >]:

and eqn. 16 for the 15 s lot [τ∈<0-0.16(6) >]:

Seed extraction heat

The obtained thermal balance shows that the amount of heat supplied to the control cones dried in a convective oven ranged from 257.46 J to 642.98 J, with the heat needed to evaporate water being 1669.37-4428.89 J (Tab. 4). The heat needed to increase cone temperature (Q1) was calculated to be 271.97-640.25 J and 740.51-1849.79 J for cones initially exposed to microwaves for 5 s and 15 s, respectively. In turn, the mean amount of heat necessary to evaporate water (Q2) was 84.76 J and 1052.57 J for cones exposed to microwaves for 5 s and 15 s, respectively. The total heat needed for seed extraction, as computed from eqn. 4, was 2163.79-5068.08 J for lot 5 s and 3007.05-6750.64 J for lot 15 s.

Tab. 4 - Seed extraction heat (expressed in J) for control cones (C) and cones exposed to microwave irradiation for 5 s (“5”) and 15 s (“15”). (Q1): amount of heat supplied to the cone to reach the drying temperature; (Q2): amount of heat needed for water evaporation during seed extraction; (Q): heat of extraction (sum of Q1 and Q2); (M): heat calculated for microwave exposure time; (PM): heat calculated for the seed extraction period after exposure to microwaves; (MPM): sum of seed extraction heat for both stages (microwaves irradiation and convection drying). (SD): standard deviation; (CV): coefficient of variation; (SE): standard error.

| Variable | Mean | Min | Max | Range | Variance | SD | CV | SE |

|---|---|---|---|---|---|---|---|---|

| Q1 C | 418.09 | 257.46 | 642.98 | 385.52 | 9992.8 | 99.96 | 23.91 | 17.95 |

| Q2 C | 2780.10 | 1669.37 | 4428.89 | 2759.52 | 458593.5 | 677.20 | 24.36 | 121.63 |

| Q C | 3198.20 | 1926.83 | 5070.73 | 3143.90 | 600941.1 | 775.20 | 24.24 | 139.23 |

| Q1 5 | 457.71 | 271.97 | 640.25 | 368.28 | 11311.0 | 106.35 | 23.24 | 18.80 |

| Q2 5 M | 84.76 | 23.55 | 155.40 | 131.85 | 1121.0 | 33.49 | 39.50 | 5.92 |

| Q 5 M | 542.47 | 295.51 | 753.62 | 458.11 | 15386.0 | 124.04 | 22.87 | 21.93 |

| Q1 5 PM | 407.86 | 243.64 | 571.02 | 327.38 | 9033.0 | 95.04 | 23.30 | 16.80 |

| Q2 5 PM | 2566.11 | 1624.63 | 3830.84 | 2206.20 | 311131.0 | 557.79 | 21.74 | 98.60 |

| Q 5 PM | 2973.97 | 1868.27 | 4382.83 | 2514.56 | 416670.0 | 645.50 | 21.71 | 114.11 |

| Q 5 MPM | 3516.44 | 2163.79 | 5068.08 | 2904.29 | 580192.0 | 761.70 | 21.66 | 134.65 |

| Q1 15 M | 1127.92 | 740.51 | 1849.79 | 1109.28 | 80562.0 | 283.83 | 25.16 | 50.18 |

| Q2 15 M | 1052.57 | 541.54 | 1980.17 | 1438.62 | 88940.0 | 298.23 | 28.33 | 52.72 |

| Q 15 M | 2180.49 | 1420.09 | 3829.96 | 2409.87 | 299574.0 | 547.33 | 25.10 | 96.76 |

| Q1 15 PM | 355.15 | 232.22 | 570.85 | 338.64 | 8376.0 | 91.52 | 25.77 | 16.18 |

| Q2 15 PM | 1641.72 | 894.73 | 2670.05 | 1775.32 | 196848.0 | 443.68 | 27.02 | 78.43 |

| Q 15 PM | 1996.87 | 1151.80 | 3193.10 | 2041.31 | 281204.0 | 530.29 | 26.56 | 93.74 |

| Q 15 MPM | 4177.36 | 3007.05 | 6750.64 | 3743.59 | 1024785.0 | 1012.32 | 24.23 | 178.95 |

Weight, number, and quality of extracted seeds

Descriptive statistics for the weight and number of seeds extracted from pine cones are reported in Tab. 5. Seed weight accounted on average for 2% of the initial weight of cones. A significant correlation was found between the weight of the extracted seeds and cone length and initial weight (R = 0.385 and R = 0.539, respectively).

Tab. 5 - Seed weight (SW, g) and number of seeds per cone (N, pcs.) obtained from the three studied lots of pine cones. (SD): standard deviation; (CV): coefficient of variation; (SE): standard error of the mean.

| Lot | Param | Mean | Min | Max | Range | Variation | SD | CV | SE |

|---|---|---|---|---|---|---|---|---|---|

| 5 s | SW | 0.172 | 0.067 | 0.320 | 0.253 | 0.005 | 0.072 | 41.731 | 0.013 |

| N | 23 | 10 | 44 | 34 | 77 | 9 | 38 | 1.6 | |

| 15 s | SW | 0.156 | 0.050 | 0.342 | 0.292 | 0.004 | 0.064 | 41.271 | 0.011 |

| N | 20 | 4 | 37 | 30 | 54 | 7 | 36 | 1.3 | |

| C | SW | 0.201 | 0.075 | 0.421 | 0.346 | 0.007 | 0.085 | 38.581 | 0.015 |

| N | 27 | 10 | 48 | 38 | 73 | 9 | 31 | 1.5 |

The results of the seed quality evaluation are presented in Tab. 6. It is worth noting that a 5 s exposure to microwaves did not significantly affect the quality of pine seeds as compared to the controls, while 15 s of irradiation dramatically damaged 100% of the seeds (none germinated).

Tab. 6 - Assessment of germination quality for seeds from the three studied lots. (Ge14d): germination energy at 14 days (%); (Gc28d): germination capacity at 28 days (%); (Mean Gc): Mean germination capacity (%).

| Lot | Sample no. |

Ge14d (%) |

Gc28d (%) |

Quality class | Mean Gc (%) | Mean quality class |

|---|---|---|---|---|---|---|

| 5 s | 1 | 86 | 90 | II | 93 | I |

| 2 | 92 | 97 | I | |||

| 3 | 86 | 90 | II | |||

| 4 | 92 | 96 | I | |||

| 15 s | 1 | 0 | 0 | - | 0 | - |

| 2 | 0 | 0 | - | |||

| 3 | 0 | 0 | - | |||

| 4 | 0 | 0 | - | |||

| Control | 1 | 91 | 93 | I | 94 | I |

| 2 | 96 | 99 | I | |||

| 3 | 90 | 91 | I | |||

| 4 | 91 | 92 | I |

Analysis of variance revealed no statistical differences in the germination energy (p = 0.221 and F = 1.862) and capacity (p = 0.854 and F = 0.0368) between seeds from control cones and those exposed to microwaves for 5 s.

Discussion

The process of cones drying using microwave irradiation, which is part of the seed extraction process, was carried out in a typical manner. The decrease in humidity was similar to that observed by Orlowska ([24]).

The microwave power applied in the present study led to strong seed damage after 15 s, therefore a shorter exposure time is desirable. Further, a 5 s microwave treatment resulted in first class cones. The increased seed extraction heat in cones exposed to microwaves was associated with the fact that their temperature surged in the first extraction step. Aniszewska ([3]) reported that cone temperature rose to 52 °C after 5 s of microwave irradiation and to almost 100 °C after 15 s. Aniszewska & Slowinski ([4]) and Rukuni ([32]) reported that cone exposure to 800 W microwave irradiation for up to 30 s did not compromise seed viability. The former authors irradiated cones placed one next to another on a tray, with the irradiation distributed across all cones. In contrast, in the present study, microwaves acted on individual cones placed in the middle of a rotating glass vessel, which means that they had a more focused effect. The treatment time was short, but in most cases sufficient for the scales to separate.

Aladjadjiyan ([1]), and Radzevičius et al. ([30]) reported that the use of microwave irradiation with a correct selection of parameters can lead to an increase in germination capacity and energy. Microwaves irradiation has been found to accelerate seed extraction, but it should be examined whether the treated seeds are weaker and equally suitable for long-term storage ([37]). Based on our results, the germination capacity and energy of seeds from cones subjected to 5 s microwave irradiation did not differ significantly from those of seeds from control cones.

In this study, the microwave treatments affected seed extraction, lowered initial moisture content, and modified the drying curve, as proven by the comparison of b coefficients. Nonetheless, these findings should be verified on a larger sample of cones of diverse origins and with different values of initial moisture content.

The process of seed extraction from Scots pine cones subjected to initial microwave irradiation may be described using a linear equation for moisture content changes induced by microwave heating, and using an exponential equation for those induced by convective heating. In the latter case, the characteristic values are the initial moisture content uo, the final moisture content uk, and the b coefficient, which on average amounted to 0.227 kgH2O kgdw-1, 0.057 kgH2O kgdw-1, and 0.31 1 h-1, respectively, for cones which were initially subjected to a 5 s microwave pre-treatment.

The proposed mathematical description of seed extraction process with a preliminary microwave treatment followed by convective drying may be used to determine the course of cone opening and seed release.

The irradiation of cones with microwaves for 15 s decreased their moisture content by an average of 7%. Due to the need to maintain seed viability, convection drying with temperature control should be used in the further drying process. The reduction of moisture content obtained through microwave irradiation reduces the next convection drying stage by about 2 hours at 35 °C or by about 1 hour at 50 °C. On average, the initial reduction of cones moisture content by 0.5% results in a reduction of convection drying time at 35 °C by 8 minutes.

The application of microwave irradiation in the process of seed extraction from Scots pine cones may be beneficial, but requires further study involving cone exposure to lower microwave powers (less than the 800 W setting used in the present experiments) and different microwave frequencies.

Conclusions

The application of microwaves with a power of 800 W before seed extraction from Scots pine cones with a mean moisture content of 23% decreased cone moisture and caused some scales to separate.

Individual pine cones exposed to a microwave power of 800 W for 5 s yielded first-class seeds. However, our results suggest that further moisture decreases could be attained by extending the treatment duration at a lower power. At the studied microwave power, however, cone exposure must be shorter than 15 s to reduce the risk of seed damage. This finding should be confirmed in further laboratory studies.

The proposed mathematical descriptions of the process of cone drying using microwave radiation can be used (after further validation) in microwave dryer control algorithms.

The process involving a 5 s microwave pre-treatment followed by convective drying accelerated seed extraction from pine cones at low relative humidity as compared to convective drying alone. However, since the combined process required a greater energy input, a cost calculation should be performed to estimate its economic feasibility.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or no-profit sectors.

References

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

CrossRef | Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Gscholar

Authors’ Info

Authors’ Affiliation

Witold Zychowicz 0000-0001-7877-7096

Arkadiusz Gendek 0000-0002-3370-6590

Institute of Mechanical Engineering, Department of Biosystem Engineering, Warsaw University of Life Sciences - SGGW, Nowoursynowska 164, 02-787 Warsaw (Poland)

Corresponding author

Paper Info

Citation

Aniszewska M, Zychowicz W, Gendek A (2020). The effectiveness of short-term microwave irradiation on the process of seed extraction from Scots pine cones (Pinus sylvestris L.). iForest 13: 73-79. - doi: 10.3832/ifor3089-012

Academic Editor

Giacomo Goli

Paper history

Received: Mar 07, 2019

Accepted: Dec 05, 2019

First online: Feb 13, 2020

Publication Date: Feb 29, 2020

Publication Time: 2.33 months

Copyright Information

© SISEF - The Italian Society of Silviculture and Forest Ecology 2020

Open Access

This article is distributed under the terms of the Creative Commons Attribution-Non Commercial 4.0 International (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Web Metrics

Breakdown by View Type

Article Usage

Total Article Views: 41242

(from publication date up to now)

Breakdown by View Type

HTML Page Views: 34937

Abstract Page Views: 3040

PDF Downloads: 2560

Citation/Reference Downloads: 0

XML Downloads: 705

Web Metrics

Days since publication: 2193

Overall contacts: 41242

Avg. contacts per week: 131.64

Article Citations

Article citations are based on data periodically collected from the Clarivate Web of Science web site

(last update: Mar 2025)

Total number of cites (since 2020): 4

Average cites per year: 0.67

Publication Metrics

by Dimensions ©

Articles citing this article

List of the papers citing this article based on CrossRef Cited-by.

Related Contents

iForest Similar Articles

Research Articles

Conservation of Betula oycoviensis, an endangered rare taxon, using vegetative propagation methods

vol. 13, pp. 107-113 (online: 23 March 2020)

Research Articles

Influence of mother plant and scarification agents on seed germination rate and vigor in Retama sphaerocarpa L. (Boissier)

vol. 7, pp. 306-312 (online: 08 April 2014)

Research Articles

The effect of seed size on seed fate in a subtropical forest, southwest of China

vol. 9, pp. 652-657 (online: 04 April 2016)

Research Articles

Seed trait and rodent species determine seed dispersal and predation: evidences from semi-natural enclosures

vol. 8, pp. 207-213 (online: 28 August 2014)

Research Articles

Inter- and intra-annual patterns of seed rain in the black spruce stands of Quebec, Canada

vol. 10, pp. 189-195 (online: 13 December 2016)

Research Articles

Effects of brassinosteroid application on seed germination of Norway spruce, Scots pine, Douglas fir and English oak

vol. 10, pp. 121-127 (online: 02 October 2016)

Research Articles

Seed germination traits of Pinus heldreichii in two Greek populations and implications for conservation

vol. 15, pp. 331-338 (online: 24 August 2022)

Short Communications

Evidence of Alectoris chukar (Aves, Galliformes) as seed dispersal and germinating agent for Pistacia khinjuk in Balochistan, Pakistan

vol. 14, pp. 378-382 (online: 22 August 2021)

Review Papers

Soil seed banks of pioneer tree species in European temperate forests: a review

vol. 11, pp. 48-57 (online: 25 January 2018)

Research Articles

Germination and seedling growth of holm oak (Quercus ilex L.): effects of provenance, temperature, and radicle pruning

vol. 7, pp. 103-109 (online: 18 December 2013)

iForest Database Search

Search By Author

Search By Keyword

Google Scholar Search

Citing Articles

Search By Author

Search By Keywords

PubMed Search

Search By Author

Search By Keyword